Device for making capillary pipe spray interface for co-using liquid chromatography and mass spectra

A liquid chromatography and manufacturing device technology, which is applied in the field of capillary spray interface manufacturing devices, can solve the problems of time-consuming consumables and low success rate, and achieve the effects of long service life, convenient processing and high production success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is further described below by examples, but not limited to this example.

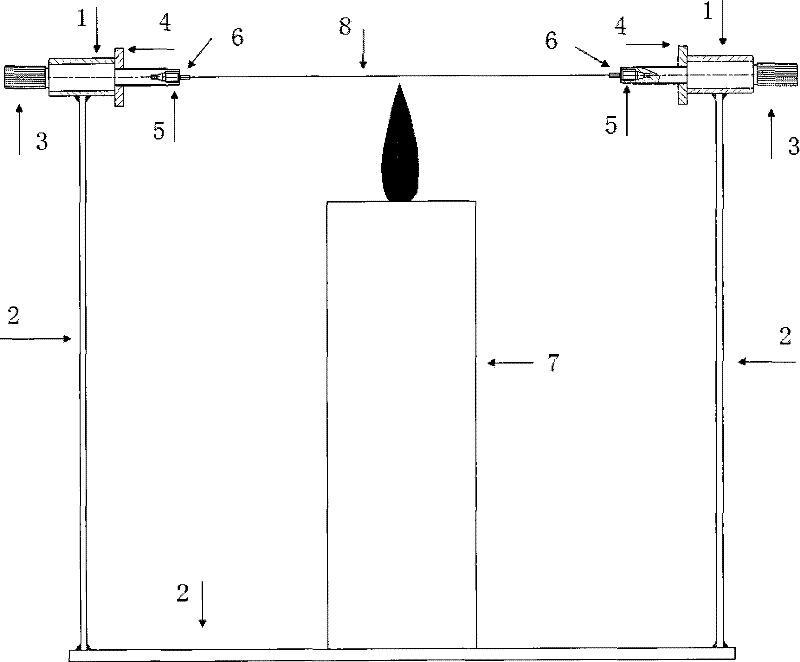

[0014] Such as figure 1 As shown, a device for making a capillary spray interface for liquid chromatography coupled with mass spectrometry, including a steel "U"-shaped support 2 for stable placement, with a height between 25-30cm, according to the temperature of the high-temperature flame designed for height;

[0015] The two tops of the vertically placed "U"-shaped bracket 2 are respectively provided with coaxial transverse chute 1, the chute 1 is a round tube with a diameter of 10-15mm, and hollow steel pipes are placed in the two chute 1 respectively. Adjusting screw rod 3 with an outer diameter of 8-12mm, the adjusting screw rod 3 can slide horizontally in the chute 1 along the horizontal direction, and can rotate along its axis in the chute 1;

[0016] The inner side of the adjusting screw 3 is respectively provided with internal threads and external threads on its i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com