Tablet machine and full-automatic slag producing machine

A tablet press, fully automatic technology, applied in the direction of presses, material forming presses, manufacturing tools, etc., can solve the problems of low processing efficiency of slag making machines, low processing efficiency, etc., to reduce scrap rate and improve processing efficiency , Improve the effect of processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

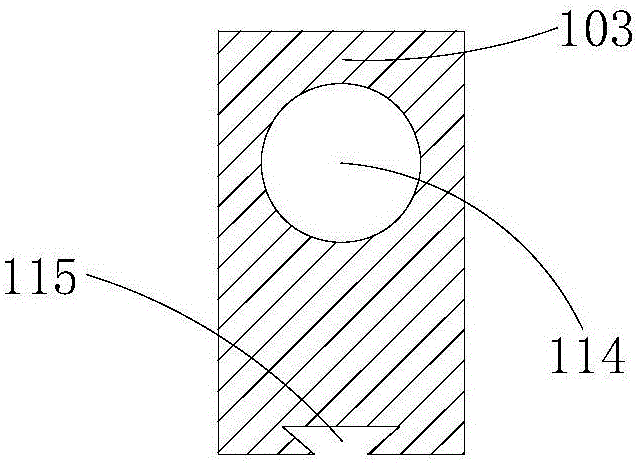

[0049] refer to Figure 1 to Figure 3 , the present embodiment provides a tablet press 119, comprising a frame 101, a mounting part 104, a steel ring 105 and a processing device 106 for processing slag, the steel ring 105 is installed on the mounting part 104, and the steel ring 105 Used to accommodate the slag, the installation part 104 is movably connected with the frame 101 , and the processing device 106 is installed on the frame 101 .

[0050] When the tablet press 119 provided in this embodiment is performing tablet compression, the installation part 104 slides on the frame 101 and brings the steel ring 105 into the processing device 106. After the processing is completed, the installation part 104 leaves the processing device with the steel ring 105 106, so as to improve the processing efficiency of the tablet press 119.

[0051] The installation part 104 and the frame 101 may be connected in a sliding manner, and the installation part 104 slides so that the steel ring...

Embodiment 2

[0058] This embodiment also provides a tablet press 119. This embodiment is a further improvement on the basis of the technical solution in Example 1. The technical solution described in Example 1 is also applicable to this embodiment. Example 1 has been disclosed The technical solution is no longer described repeatedly.

[0059] Specifically, the difference between this embodiment and Embodiment 1 is that the installation part 104 of the tablet press 119 provided in this embodiment is disc-shaped, and the plate surface of the installation part 104 is parallel to the bottom surface of the frame 101, and is installed on a The axis line rotates relative to the frame 101, and the steel ring 105 is installed on the eccentric position of the mounting part 104. When the mounting part 104 rotates, the steel ring 105 can enter the processing device 106 along the mounting part 104. When the mounting part 104 rotates again , the steel ring 105 is turned out from the processing device 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com