Method for preventing pipe plates from welding deformation through strip surfacing of high-pressure air cooler pipe plates

A technology of strip surfacing and welding deformation, used in welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as surfacing deformation, and achieve the effect of reducing the straightening process and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

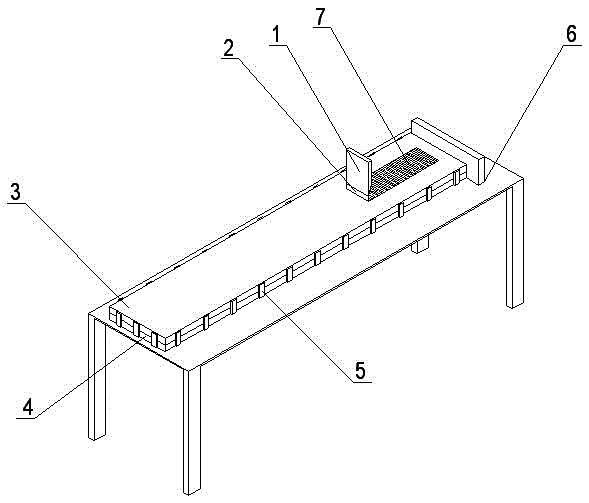

[0009] Such as figure 1 Shown, a kind of high-pressure air-cooler tube plate belt pole surfacing welding method to prevent the tube plate from welding deformation is as follows: first, the first tube plate 3 and the second tube plate 4 are welded together through a plurality of connecting plates 5 around, and then Placed on the surfacing platform and fixture 6, the welding head 1 conveys the welding strip 2, a layer of alloy is surfacing on the surface of the first tube plate 3, the workpiece is turned over, and a layer of alloy is surfacing on the surface of the second tube plate 4. One layer of welding conditions is: surfacing current 800A, voltage 28V; Flip the workpiece again, surfacing the second layer of alloy on the surface of the first tube plate 3, then turn over the workpiece, and surfacing the second layer of alloy on the surface of the second tube plate 4, The welding conditions of the second layer are: surfacing welding current 705A, voltage 28V, surfacing welding...

Embodiment 2

[0011] A method for preventing welding deformation of the tube plate by surfacing welding of the tube plate of a high-pressure air cooler is as follows: firstly, the first tube plate 3 and the second tube plate 4 are welded together through a plurality of connecting plates 5 around the first tube plate 3 and the second tube plate 4, and then placed in the pile On the welding platform and fixture 6, the welding head 1 conveys the welding strip 2, and a layer of alloy is surfacing on the surface of the first tube plate 3, the workpiece is turned over, and a layer of alloy is surfacing on the surface of the second tube plate 4, and the first layer of welding The conditions are: surfacing current 900A, voltage 26V; turn over the workpiece again, surfacing the second layer of alloy on the surface of the first tube plate 3, then turn over the workpiece, and surfacing the second layer of alloy on the surface of the second tube plate 4, the second layer The welding conditions are: surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com