Forming mold and method for aluminum alloy profile

A technology of aluminum alloy profiles and forming molds, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of insufficient mastery, high sensitivity of aluminum-lithium alloys, forming temperature, heating time, etc. problem, to achieve the effect of strong versatility, wide application, and precise control of forming temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific examples. For the convenience of the discussion, "up", "down", "left", and "right" are used to indicate the directions in each schematic diagram, which is conducive to the development of the discussion.

[0059] Such as figure 1 As shown, the present invention provides a preferred aluminum alloy profile forming die. The aluminum alloy profile here may include other various metal elements, for example, when lithium is added, it is an aluminum-lithium alloy profile. Various profiles can be integral profiles or profile parts, there is no limit to this.

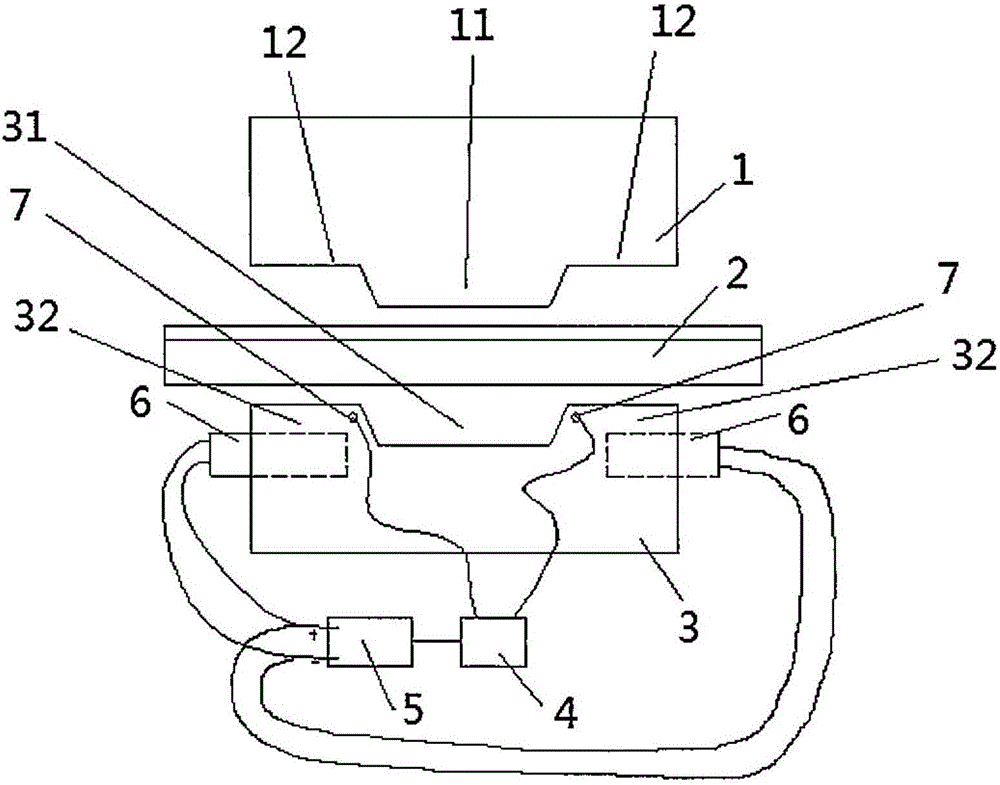

[0060] exist figure 1 Among them, the aluminum-lithium alloy profile forming die includes an upper die 1 and a lower die 3 . The upper mold 1 has a raised portion 11 , and two upper mold shoulders 12 are formed on both sides of the raised portion 11 . The lower mold 3 has a concave portion 31 corr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com