Induction device for speed adjusting of leveler

A technology of induction devices and leveling machines, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increased power consumption, achieve the effects of reducing power consumption, reducing operators, and prolonging machine life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

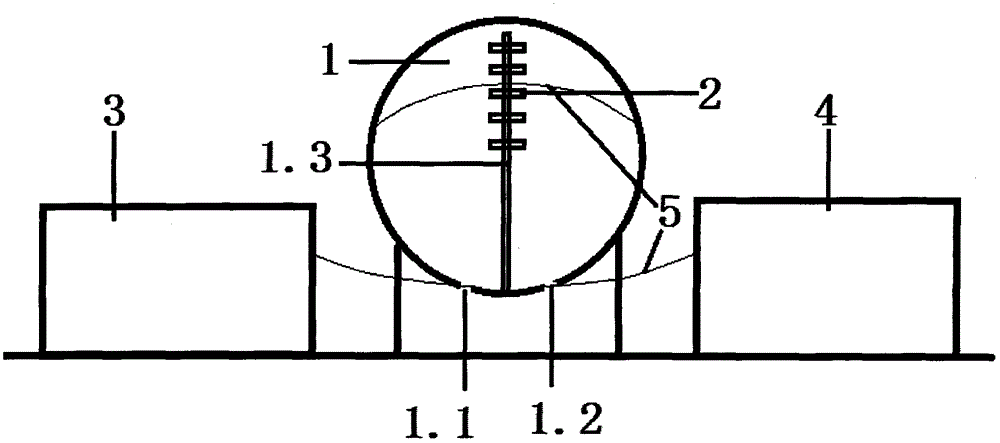

[0011] Such as figure 1 As shown, an induction device for speed regulation of a tempering machine is mainly composed of an "O" type shelf 1 and an inductor 2. The "O" type shelf 1 is arranged behind the leveling machine 3 and in front of the feeder 4 The "O" plane of the "O" shelf 1 is 180 degrees from the leveler 3 and the feeder 4, and is placed vertically. There are inlet 1.1 and outlet 1.2 of the steel bar 5 at the lower end, and the "O" shelf The track that steel bar 5 passes is housed in the lower half circle edge of 1, and vertical pole 1.3 is arranged in the middle of "O" shape shelf 1, and five inductors 2 equidistant are arranged on the upper part of pole 1.3, and inductor 2 is connected Controllers for skin pass mills and feeders.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com