Heat transfer station monitoring recording device based on accumulator read-in module (ARM)

A technology for monitoring and recording, heat exchange station, applied in the direction of household heating, household heating, heating methods, etc., can solve the problems of limited economic bearing capacity, high price of recorders, strong coupling lag, etc., to achieve stable performance and reduce operation. The effect of high integration of personnel and systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

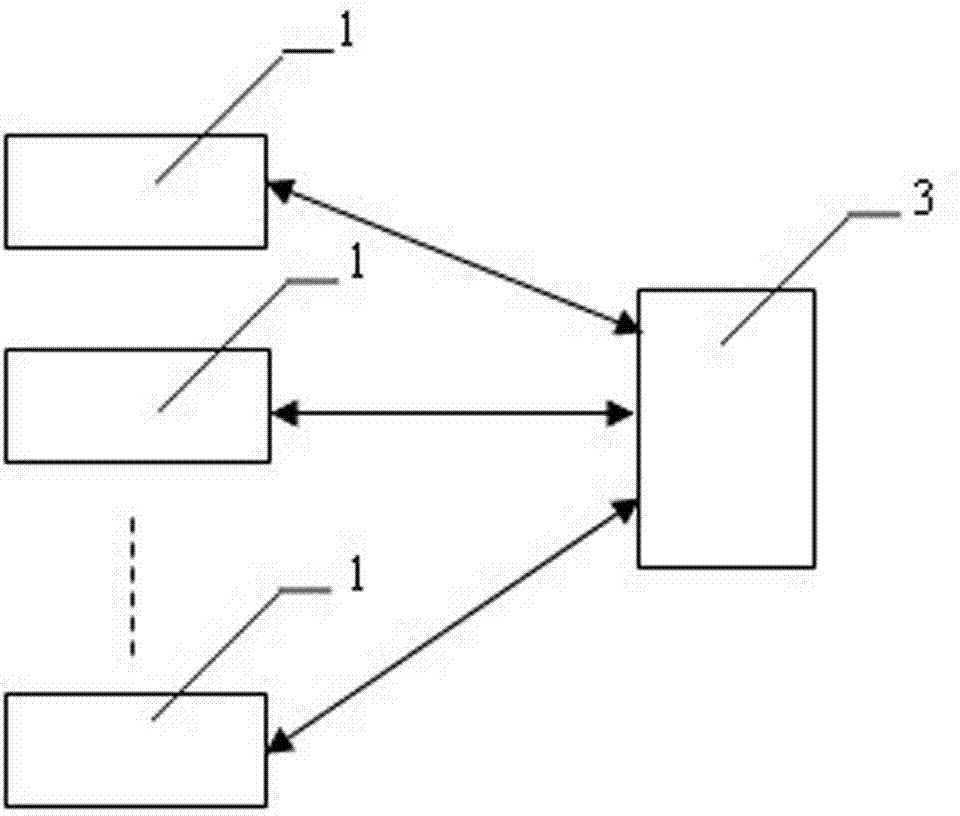

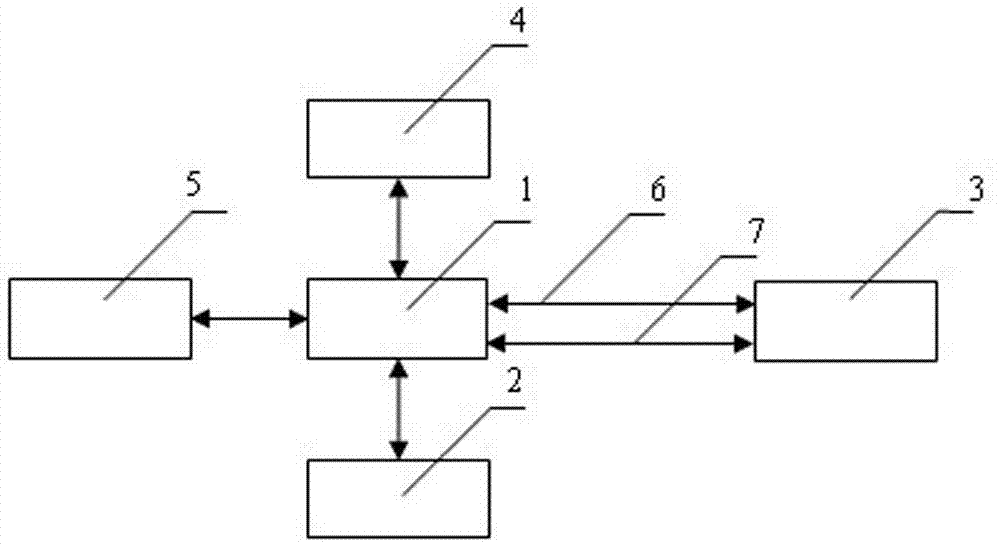

[0021] An ARM-based heat exchange station monitoring and recording device, which includes ARM11 1, camera 5, touch screen color LCD 4, upper computer 3 and single-chip microcomputer system 2, ARM11 1 automatically completes the operation of taking pictures of the camera 5, and stores it in SD through the SPI interface card, and further processing of the information. The camera 5 is installed above the operation room 13 of the heat exchange station. ARM11 1 completes the monitoring and analysis of the on-site working status locally through the processing of the collected data and displays it through the color LCD 4 on the touch screen; all the way through the GPRS module 6 or Ethernet The interface 7 is connected with the upper computer 3 of the remote monitoring station, and the data is uploaded and analyzed.

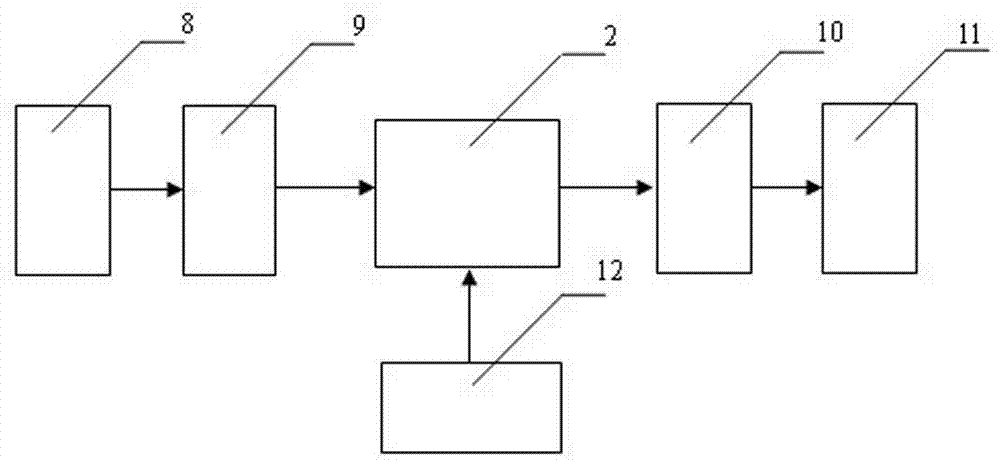

[0022] The ARM11 1 interface is connected with the microcontroller system 2 through a high-speed serial port. The single-chip microcomputer system 2 includes a photoel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com