Purifying device and purifying method for ammonia-containing mixed gas

A technology of mixed gas and purification device, which is applied in the direction of chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of high equipment cost, complex device, and low efficiency, and achieve simple device process, high heat resistance, Simple and clear effect of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

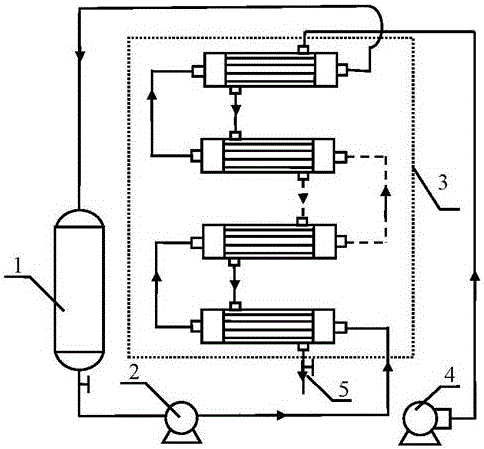

[0030] Turn on the PP pump 2, and the sulfuric acid solution with a mass concentration of 5% in the absorption liquid tank 1 enters the inside of the membrane filament of the first-stage membrane module of the three-stage membrane module 3 through the PP pump 2, and flows out from the inside of the membrane filament of the last-stage membrane module , return to the absorption liquid tank; turn on the fan 4, and the mixed gas containing ammonia at 0°C passes through the fan 4 at a speed of 1900 m 3 The air volume per hour enters the outside of the membrane filament of the last stage membrane module; the ammonia in the ammonia-containing mixed gas entering the outside of the membrane filament of the multi-stage membrane module will enter the inside of the membrane filament from the outside of the membrane filament, and the sulfuric acid solution inside the membrane filament react and be eliminated. The clean gas is discharged from the clean gas outlet of the first-stage membrane...

Embodiment 2

[0032] Turn on the PP pump 2, and the sulfuric acid solution with a mass concentration of 30% in the absorption liquid tank 1 enters the inside of the membrane filament of the first-stage membrane module of the seven-stage membrane module 3 through the PP pump 2, and flows out from the inside of the membrane filament of the last-stage membrane module , return to the absorption liquid tank; turn on the fan 4, and the mixed gas containing ammonia at 100°C passes through the action of the fan 4 at a speed of 100 3 The air volume per hour enters the outside of the membrane filament of the last stage membrane module; the ammonia in the ammonia-containing mixed gas entering the outside of the membrane filament of the multi-stage membrane module will enter the inside of the membrane filament from the outside of the membrane filament, and the sulfuric acid solution inside the membrane filament react and be eliminated. The clean gas is discharged from the clean gas outlet of the first-...

Embodiment 3

[0034] Turn on the PP pump 2, and the mass concentration in the absorption liquid tank 1 is 20%. The phosphoric acid solution enters the inside of the membrane filament of the first-stage membrane module of the fifth-stage membrane module 3 through the PP pump 2, and flows out from the inside of the membrane filament of the last-stage membrane module. , return to the absorption liquid tank; turn on the fan 4, the mixed gas containing ammonia at 80°C passes through the action of the fan 4 at a rate of 1000 m 3 The air volume per hour enters the outside of the membrane filament of the last stage membrane module; the ammonia in the ammonia-containing mixed gas entering the outside of the membrane filament of the multi-stage membrane module will enter the inside of the membrane filament from the outside of the membrane filament, and the sulfuric acid solution inside the membrane filament react and be eliminated. The clean gas is discharged from the clean gas outlet of the first-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com