Device and method for protecting evaporation tank against large salt blocks

An evaporating tank and bulk technology, which is applied in the field of vacuum salt production or co-production of salt and nitrate, can solve problems such as the inability to prevent bulk salt production, and achieve the effects of prolonging a single operation cycle, promoting dissolution, and shortening rinse time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

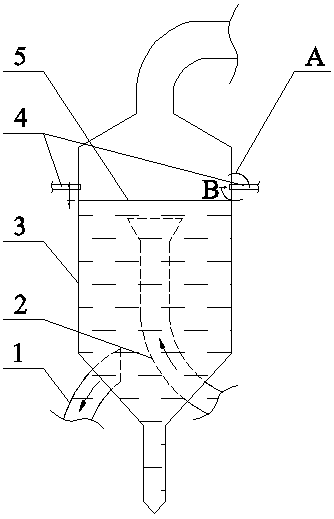

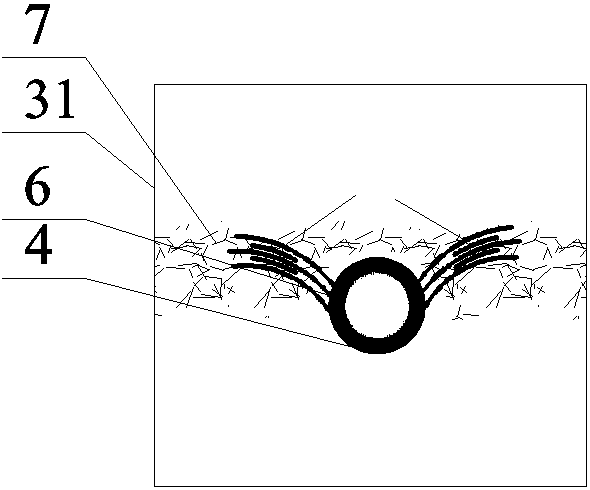

[0029] refer to figure 1 with figure 2 , a device for preventing the generation of bulk salt in the evaporating tank in this embodiment includes 4 flushing water pipes 4 that are evenly distributed on the tank wall 31 of the evaporating tank in a circumferential manner, and the distance between the flushing water pipes 4 and the liquid level of the evaporation chamber is more than 5 The vertical distance is 0.5m. One end of the flushing water pipe 4 is connected to the condensate pressurizer, and the other end passes through the tank wall 31 of the evaporation tank, and a flushing hole 6 is provided at the upper half of the end of the flushing water pipe 4 inside the tank wall. The central axis of the flushing hole 6 and the central horizontal section of the flushing water pipe 4 form an inclined angle of 30°.

[0030] The length of the flushing water pipe 4 located in the evaporation tank 3 is 0.05m.

[0031] The diameter of the flushing hole 6 is 20mm.

[0032] The flush...

Embodiment 2

[0035] refer to Figure 4 with Figure 5 , a device for preventing the formation of large lumps of salt in the evaporation tank of this embodiment, compared with Embodiment 1, there are the following differences:

[0036] The length of the flushing water pipe 4 located in the evaporation tank 3 is 0.08m.

[0037] The number of the flushing water pipes 4 is six.

[0038] The diameter of the flushing hole 6 is 15mm.

[0039] The flushing hole 6 is square.

[0040] The flushing water pipe 4 is provided with a solenoid valve 9 , and the solenoid valve 9 is connected with a time relay 8 .

Embodiment 3

[0042] A method for preventing block salt generation in an evaporating tank, comprising the following steps:

[0043] 1) Install at least four flushing water pipes 4 on the tank wall 31 of the evaporation tank above the liquid level 5 in the evaporation chamber, so that the flushing water pipes 4 are evenly distributed on the tank wall 31 of the evaporation tank in a circular manner, and the vertical distance from the liquid level 5 in the evaporation chamber ≤1m;

[0044]2) Set the interval time of the time relay 8 and the water flow time through the salt production control system, so that the solenoid valve 9 on the flushing water pipe 4 is opened at intervals, so that the flushing water pipe 4 is passed through water, and the tank wall 31 of the evaporation tank is flushed , when the water passing time reaches the set value, the solenoid valve 9 is closed, and the flushing water pipe 4 stops passing water, such as the device in embodiment 2; or, the water passing time of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com