[0009] Above-mentioned background technology 2 has following defect: (1) the microcomputer electric rice cooker of Japanese Toshiba Company invention in 1982, is to replace manual operation with chip programming, the temperature of liquid food in the pot is controlled below boiling point, can not produce boiling state at all, It is not a real anti-overflow pot without breaking through the original anti-overflow method of "no boiling or overfilling"; (2) The instruction manual of the Panasonic SR-MS183 microcomputer electric rice cooker in Japan clearly requires: whether cooking porridge or soup Half pot or small half pot, the heating time is set to "1-4 hours", and the length of the heating time period cannot be automatically adjusted according to the amount of food, so it is doomed to set an unscientific long heating time and waste energy; (3) When the rice boils, the soup will stick to the overflow-proof pot cover and even flow out of the overflow-proof pot cover. It needs to be scrubbed, which is troublesome, wasteful and unhygienic. Therefore, it is not possible to steam food while cooking food. The steamer lacking practicality is useless; (4) The amount of liquid food to be cooked is limited by the scale. You can only cook half a pot at most, but there will still be juice sticking to the overflow-proof pot cover or even gushing out the overflow-proof pot cover. It needs to be scrubbed, which is troublesome, wasteful, and unhygienic; (5) ) Because the temperature when cooking liquid food is controlled below the boiling point, it takes a long time to cook semi-liquid food such as noodles and dumplings slowly—it will be rotten when it is cooked

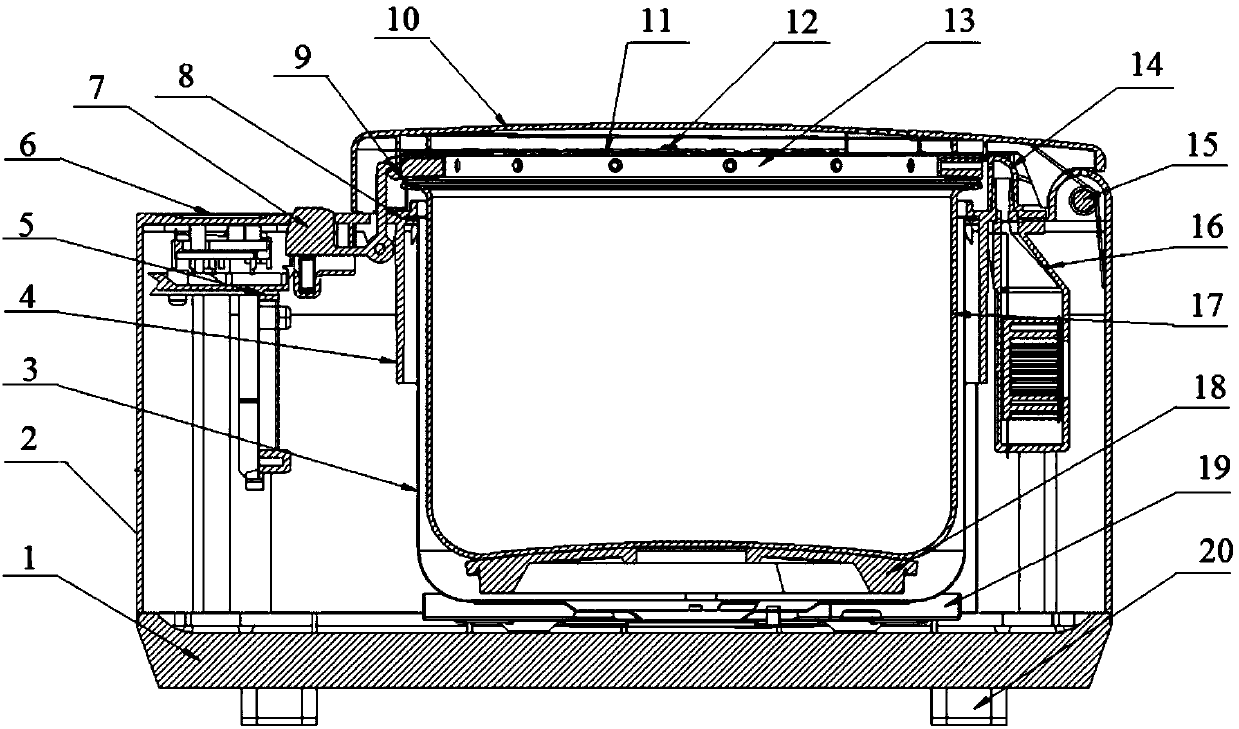

[0011] (1) Defects of the pot body: no breakthrough has been followed for 34 years. The manufacturing method of the traditional electric rice cooker pot body that is neither round, oval, nor square, or rectangular. The pattern is rigid and lacks novelty and creativity. The mold manufacturing process of the pot body is complicated, the production cost is too high, and the production efficiency is too low; there is no reinforcement at the bottom of the pot body, and the stability and loadability are poor. It cannot be used for cooking, and the practicability is single; the bottom surface of the pot body is not provided with vent holes, resulting in insufficient air supply and reducing the anti-overflow effect. Rice, when cooking thick food, vegetable soup, etc., will overflow the pot after boiling, and the anti-overflow probability is only 60%

[0012] (2) Defects of the anti-overflow pot cover: there are main cover and auxiliary cover, which cause the anti-overflow cover to be too thick, too heavy, and unsightly; the main cover and auxiliary cover make the thickness of the anti-overflow cover increase 17mm, wasting raw materials, increasing production costs, and reducing production efficiency; the division of main cover and auxiliary cover increases the manufacturing process, increases production costs, and reduces production efficiency; divides a spill-proof pot cover into main and auxiliary A spill-proof pot cover destroys the integration of the spill-proof pot cover and reduces the strength and service life of the spill-proof pot cover; because only the secondary cover has vent holes, and the area of the secondary cover is too small, the vent holes If it is too small, the discharge of steam will be severely hindered, so the food in the steamer will not be cooked when the food is cooked in the pot, and the energy cannot be reused and energy can not be saved

[0013] (3) Defects of the anti-overflow pot table: the pot body is manufactured by injection molding after the mold is opened

As an important part of the pot body, that is, the layout of the anti-overflow pot table, it is an obvious waste not to achieve multiple uses on one level; failing to achieve multiple uses on one side will inevitably increase the number of parts and affect the whole machine The degree of integration reduces the strength and service life of the whole machine, increases the manufacturing process, increases production costs, and reduces production efficiency.

[0014] (4) Defects of the anti-overflow air duct: the anti-overflow air duct is an arc-shaped duct composed of an upper half with a semicircular cross-section buckled on the lower half with a groove-shaped cross-section

The installation of the edge of the lower half is only arranged in the middle section of the two end faces and the outer side, and there is no installation on the side facing the inner pot, which will cause air leakage and reduce the anti-overflow effect; the contact between the bottom of the lower half and the anti-overflow pot platform There is no rubber gasket, which will cause air leakage and reduce the anti-overflow effect; there is a ring on the lower half, the height of the ring is only 5mm, and there is no fastening device between the upper half and the lower half, so the upper half is very It is easy to be loosened by the wind blown in by the anti-overflow fan, which is easy to leak air and reduce the anti-overflow effect; the length of the anti-overflow air duct is "a curved pipe equivalent to 35% of the circumference set along the edge of the outer pot mouth ", too short, the air pressure formed by the air ejected from the air hole in the space of the pot mouth is not enough to break the thick foam. For the above five types of food, its anti-overflow function is limited to cooking liquid, thin, and rice. Cooking other types of food will overflow the pot when boiling, and the anti-overflow probability can only reach 60%, which is one of the root causes of the whole machine becoming an incomplete anti-overflow pot

[0015] (5) Defects of the anti-overflow fan: the air outlet of the anti-overflow fan and the air inlet of the anti-overflow duct have the same length on the left and right, but the front and rear widths are different. The width of the former is 6.8mm, and the width of the latter is 4mm. It is 2.8mm narrower than the former, forming a step. This step becomes the resistance to the air ejected from the outlet of the anti-overflow fan, which causes too much noise when the anti-overflow fan works, and affects the anti-overflow effect; the anti-overflow fan faces the inner pot There is still 2.5mm away from the insulation skirt of the box body, so that the distance between the air outlet of the overflow-proof duct and the air hole of the anti-overflow pot cover is relatively large, which reduces the wind force from the air outlet to the center of the inner pot, thus reducing the Anti-overflow function; in order to enhance the installation effect and prevent air leakage, there must be a groove around the outlet of the anti-overflow fan to place the rubber gasket

However, the space where the air outlet faces the inner pot is too narrow, and the groove for placing the rubber gasket can only be made very small and narrow, which has a negative impact on the installation effect and the function of preventing air leakage, and it is easy to fall off and cause As for falling into the fan body and causing entanglement, the fan will be damaged.

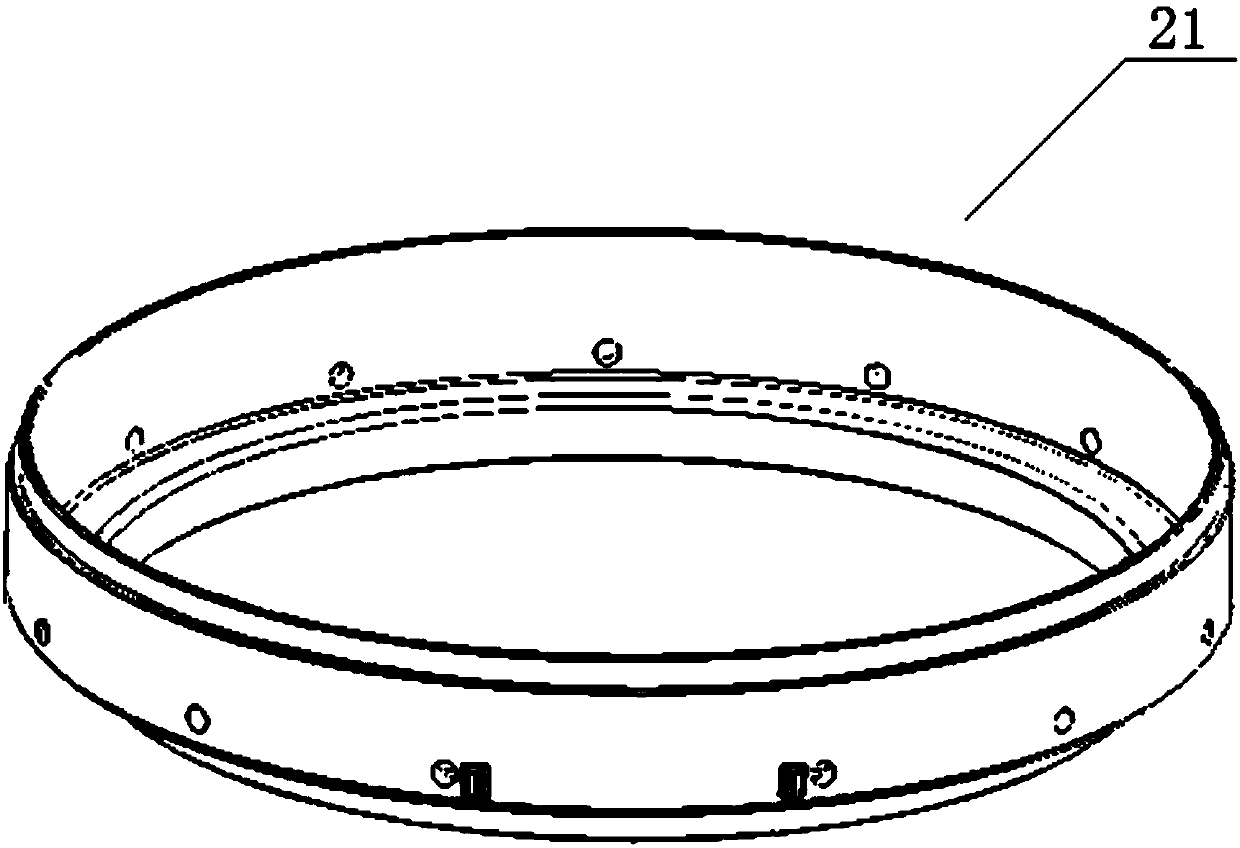

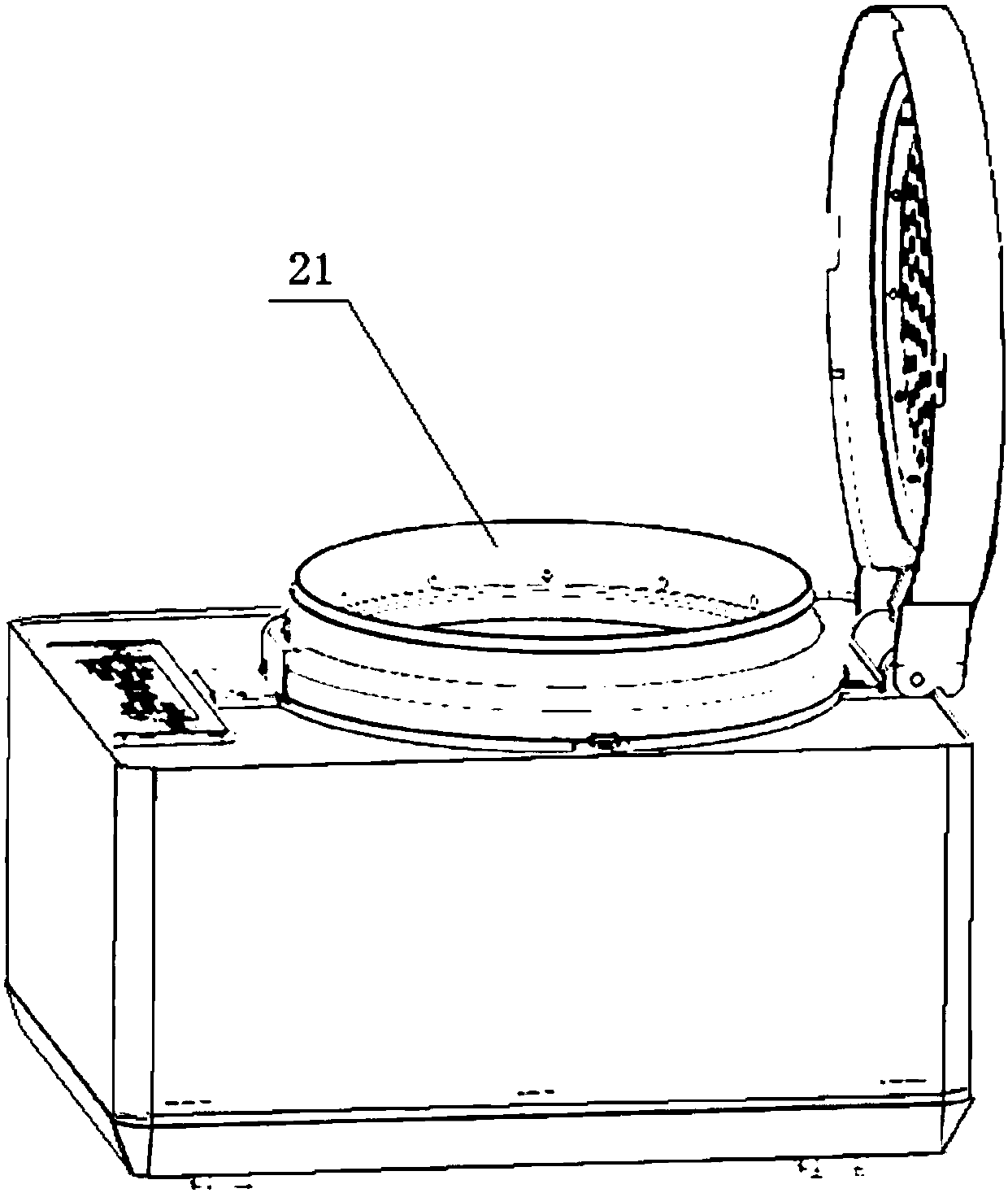

[0016] (6) Defects of the anti-overflow steamer: the anti-blocking column on the inner wall is very heavy, and it will be deformed after injection molding, which is not beautiful; the anti-blocking column is too wide and too thick, which wastes raw materials; the anti-blocking ring on the bottom surface is circular , the distance between the rings is very large, the anti-scalding rings on the bottom of rice bowls and vegetable dishes are also circles, and the anti-scalding rings embedded in the gaps of the blocking rings will block the vent holes on the bottom of the steamer. For anti-overflow function, steamed food The efficiency of the steamer has a negative impact; the positioning ring on the bottom surface is too small, reducing a lot of vent holes, resulting in serious obstruction of steam discharge, so the food in the steamer cannot be steamed while cooking food, and energy cannot be reused, which cannot be realized energy saving purpose

[0017] (7) Defects of the steamer cover: there is a circular empty window in the middle of the steamer cover, and the circular empty window must be covered with a secondary cover to realize the function of "cover". The structure is cumbersome, which increases the process flow, wastes raw materials, and reduces Increased production efficiency, increased production costs, troublesome use

Login to View More

Login to View More  Login to View More

Login to View More