Preparing and use method for additive capable of improving quality of flue-cured tobacco leaf in tobacco leaf modulation stage

A technology of additives and flue-cured tobacco, which is applied in the fields of tobacco, application, and treatment of tobacco, can solve problems such as a certain gap in compatibility, and achieve the effects of low cost, simple operation, and improved grade structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation of additives:

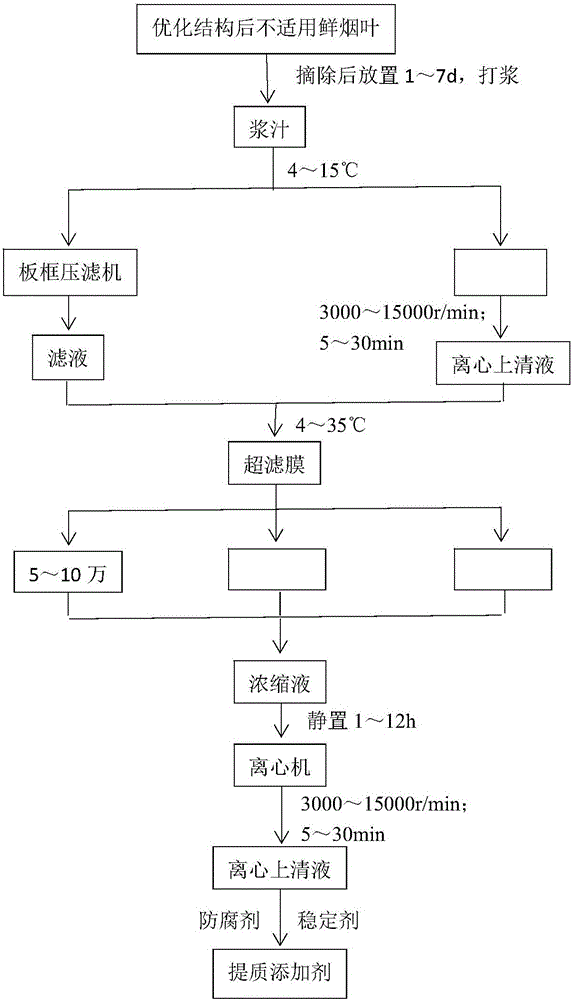

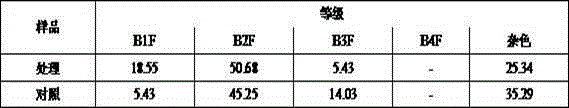

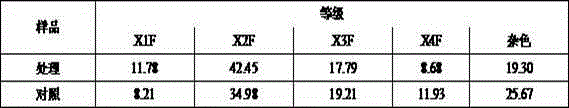

[0026] (1) The preparation process route is as follows: figure 1 shown. The unsuitable lower two fresh tobacco leaves (as shown in Figure 2) were used as raw materials for the optimized structure of Yunyan 87 flue-cured tobacco variety in Kunming Tobacco Area, Yunnan.

[0027] (2) After the juice is homogenized, filter it with a plate and frame filter press at 10°C to collect the filtrate;

[0028] (3) Concentrate the filtrate with an ultrafiltration membrane at 25°C. The primary cut-off molecular weight is 100,000. After 24 hours of ultrafiltration, the concentrated solution is collected to obtain component 1; the filtrate is subjected to secondary separation, and the cut-off molecular weight is 50,000. After 24 hours of ultrafiltration, the concentrated solution is collected to obtain component 2; the filtrate is subjected to the third stage Separation, the molecular weight cut-off is 20,000, after ultrafiltration for 48 hours, the conce...

Embodiment 2

[0042] Preparation of additives:

[0043] (1) The preparation process such as figure 1 shown. The unsuitable upper two tobacco leaves (as shown in Figure 2) were used as raw materials for K326 variety K326 tobacco leaf structure optimized in the Kunming Tobacco Area of Yunnan Province.

[0044] (2) After the juice is homogenized, centrifuge in a centrifuge at 15°C at a speed of 10,000 r / min for 10 minutes, and collect the centrifuged supernatant;

[0045] (3) The filtrate was concentrated by ultrafiltration membrane at 20°C. The primary cut-off molecular weight is 100,000. After 36 hours of ultrafiltration, the concentrated solution is collected to obtain component 1; the filtrate is separated by an ultrafiltration membrane with a cut-off molecular weight of 30,000. After 30 hours of ultrafiltration, the concentrated solution is collected to obtain component 2; The grade cut-off molecular weight was 10,000, and component 3 was obtained after ultrafiltration for 24 hours. ...

Embodiment 3

[0059] Preparation of additives:

[0060] (1) The preparation process such as figure 1 shown. The unsuitable upper two tobacco leaves (as shown in Figure 2) were used as raw materials for the optimized tobacco leaf structure of the red variety in the Kunming Tobacco Area of Yunnan.

[0061] (2) After the juice is homogenized, centrifuge in a centrifuge at 8°C at a speed of 3000 r / min for 20 minutes, and collect the centrifuged supernatant;

[0062] (3) The filtrate was concentrated using an ultrafiltration membrane at 30°C. The primary molecular weight cut-off is 80,000. After 25 hours of ultrafiltration, the concentrated solution is collected to obtain component 1; the secondary molecular weight cut-off is 40,000. After 20 hours of ultrafiltration, the concentrated solution is collected to obtain component 2; the third-stage molecular weight cut-off is 20,000. Component 3 was obtained after ultrafiltration for 20 h.

[0063] (4) Combine components 1 and 2, let stand for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com