Fully automatic double-sided screen-printing machine

A screen printing machine, fully automatic technology, applied in the direction of printed circuit, printed circuit manufacturing, electrical components, etc., can solve the problems of high manufacturing cost, high equipment occupation, difficult to use, etc. of fully automatic double-sided screen printing machine, and achieve saving of screen printing stations , Reduced manufacturing cost, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

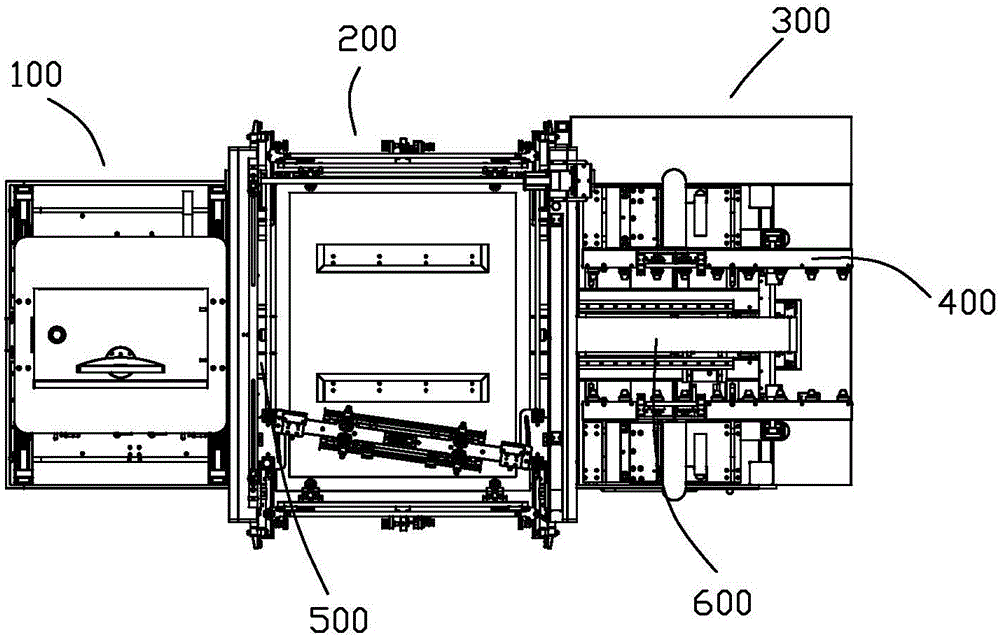

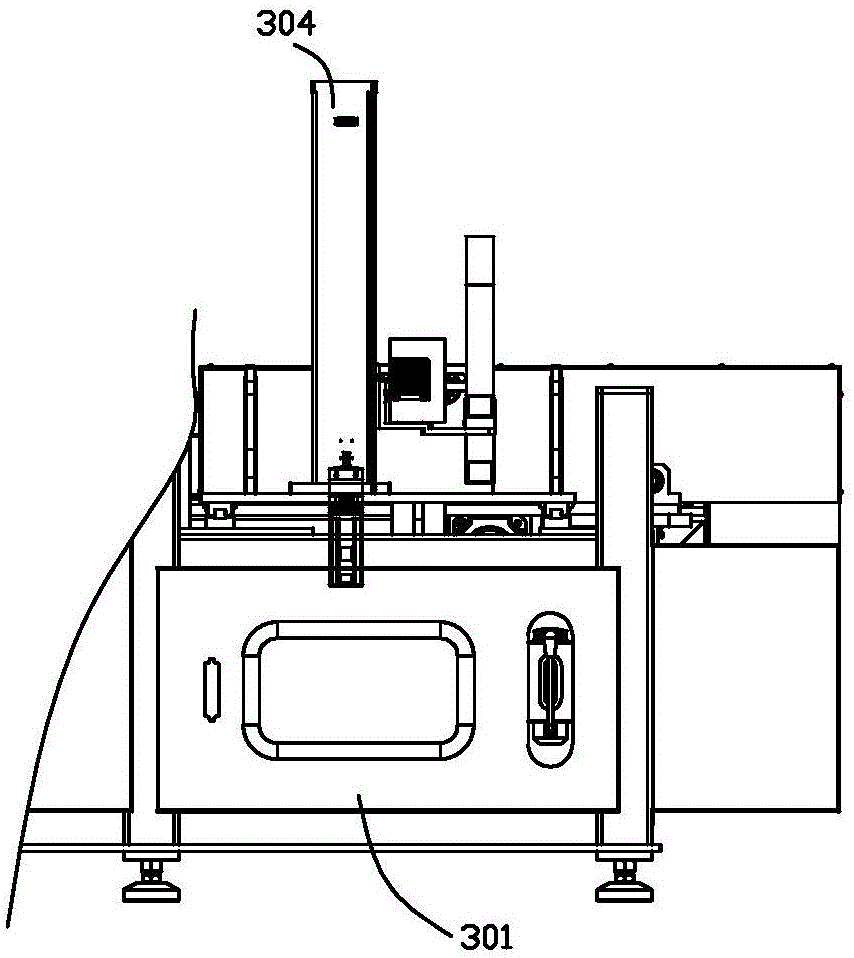

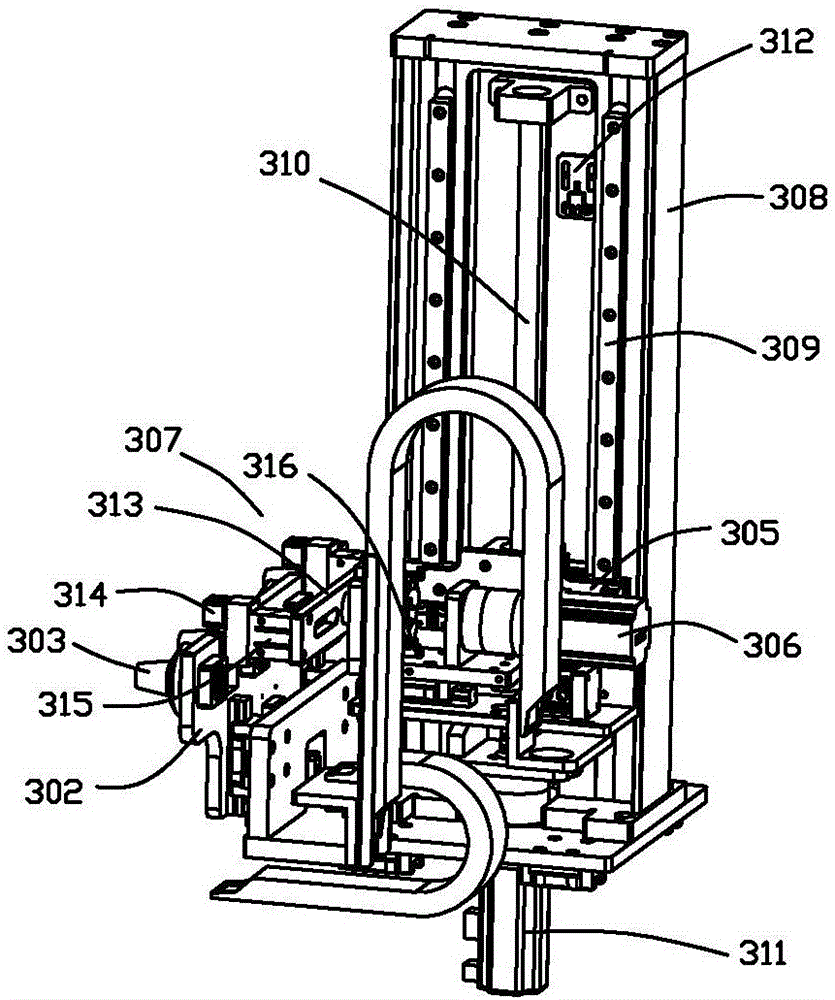

[0017] refer to figure 1 , the fully automatic double-sided screen printing machine of the present invention includes an alignment station 100, a screen printing station 200, and a turnover station 300 arranged in sequence, and the turnover station 300 is connected to a discharge conveyor track 400. The present invention also includes a first feeding table 500 that can be displaced horizontally and linearly between the alignment station 100 and the silk screen printing station 200 and a second feeding table that can be displaced horizontally and linearly between the silk screen printing station 200 and the turnover station 300 600.

[0018] The horizontal linear displacements of the first feeding table 500 and the second feeding table 600 are synchronized. In practice, both are generally driven by the same horizontal displacement driving device to perform horizontal linear displacement. refer to figure 1 , the first feeding table and the second feeding table can move to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com