Fast Magnetic Heater

An electromagnetic heater, fast technology, applied in the direction of induction heating, coil device, etc., can solve the problems of limited development and application, bulky, slow heating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

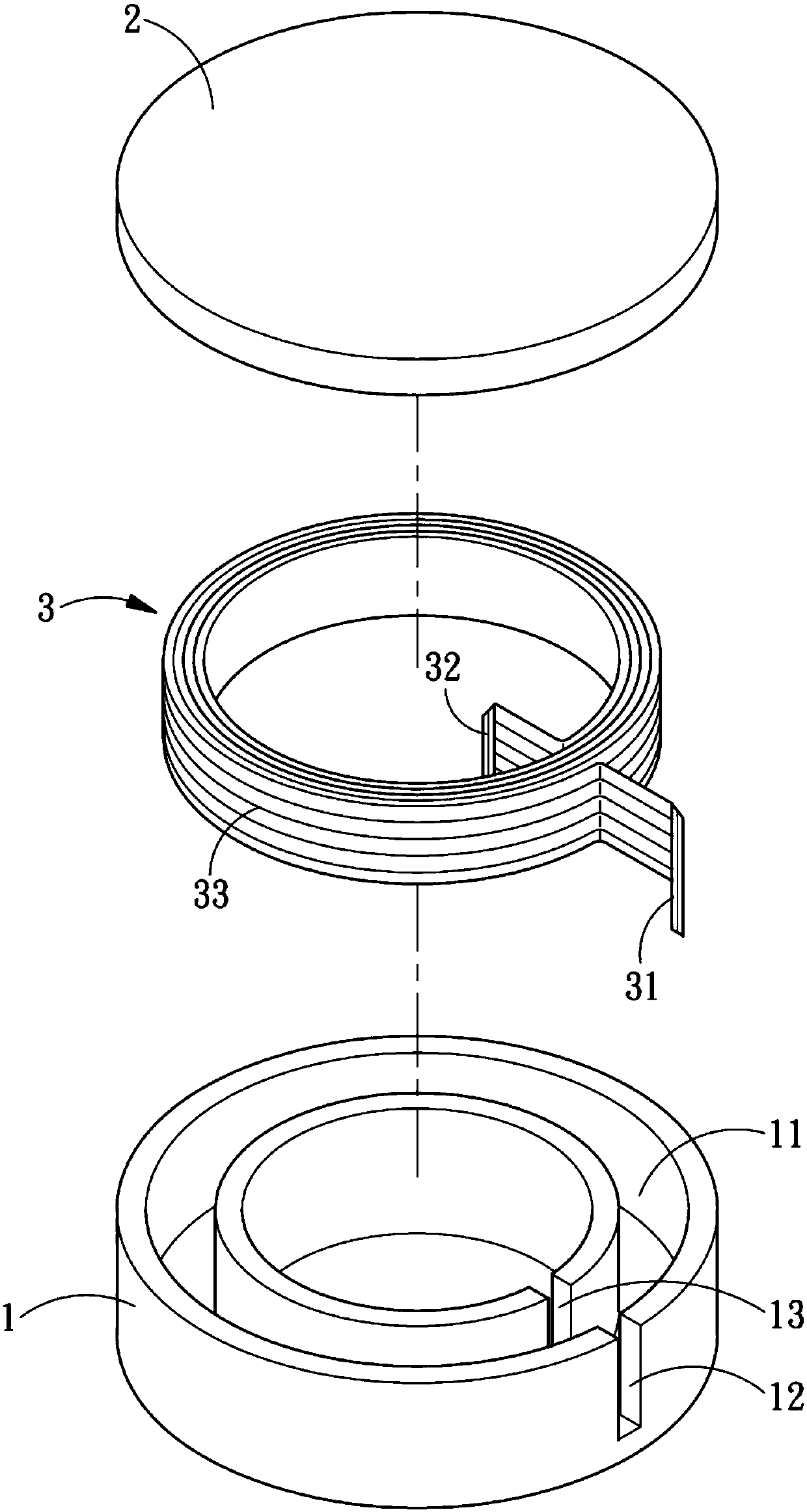

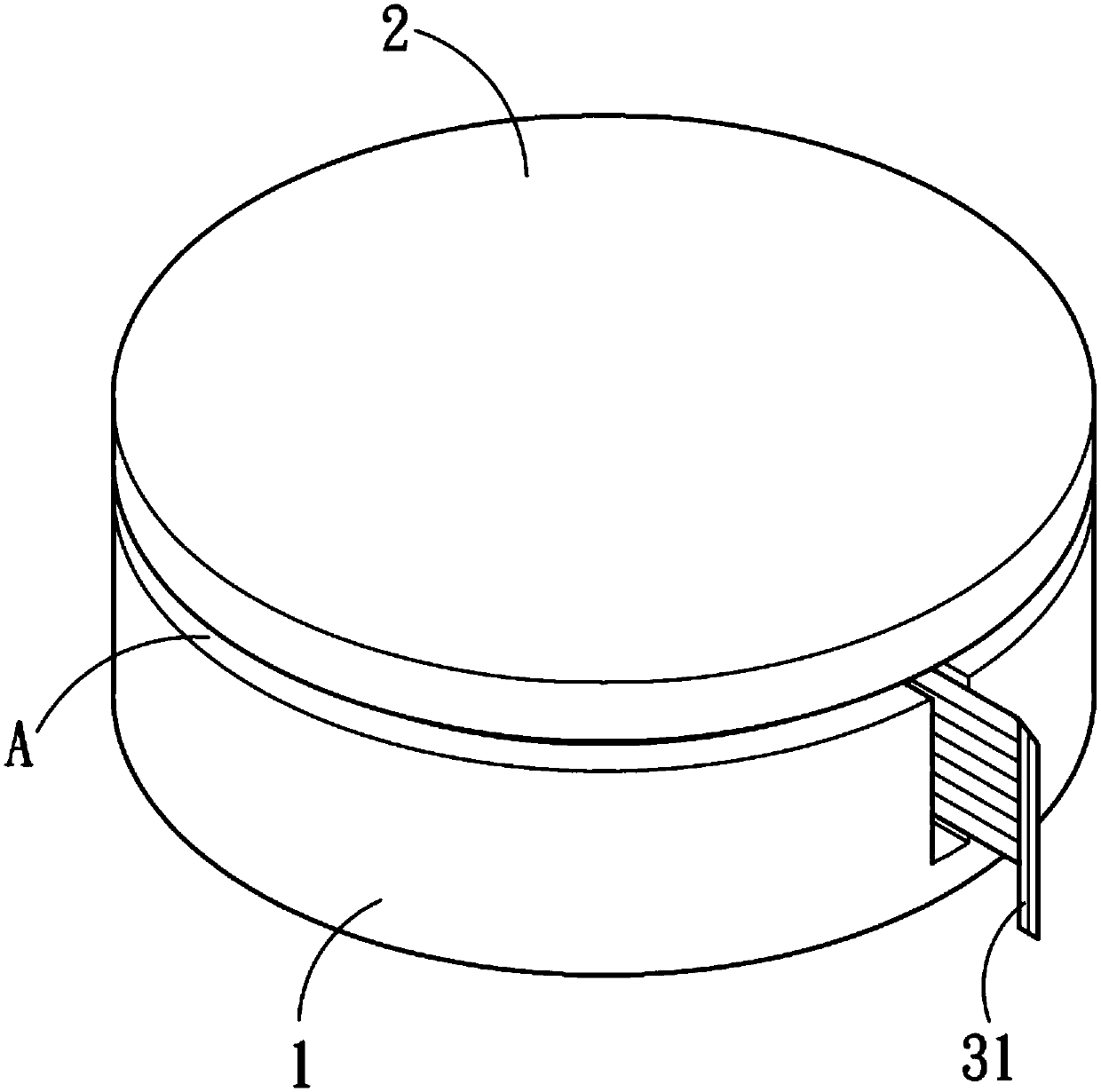

[0030] see Figure 1 to Figure 4 As shown, it can be seen that the structure of the first embodiment of the present invention mainly includes: a ferrite base 1, a magnetically conductive heating plate 2, and an electromagnetic winding 3; wherein the ferrite base 1 is a ferrite (fgrrite ) material integrally formed ring structure, the top surface of the ring body is concavely provided with an annular accommodation groove 11, and the inner and outer sides of the accommodation groove 11 are respectively provided with at least one or more slits 12, 13 , so that the side of the aforesaid accommodating groove 11 can communicate with the outside through the two slits 12 , 13 .

[0031] The magnetic conduction heating plate 2 is a highly permeable metal (which can be iron) sheet structure with the same shape as the periphery of the ferrite seat 1. above groove 11.

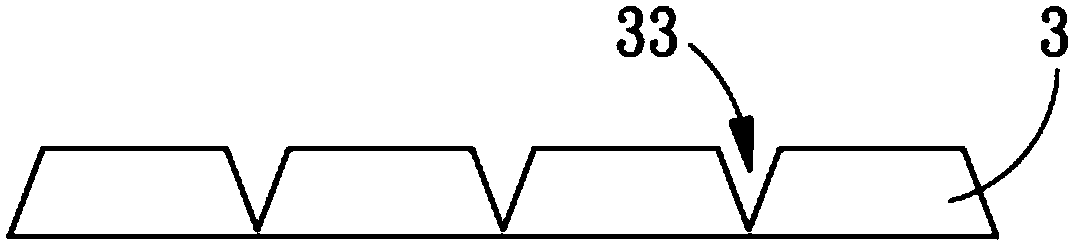

[0032] The electromagnetic winding 3 is arranged in the accommodating groove 11 of the aforementioned ferrite seat 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com