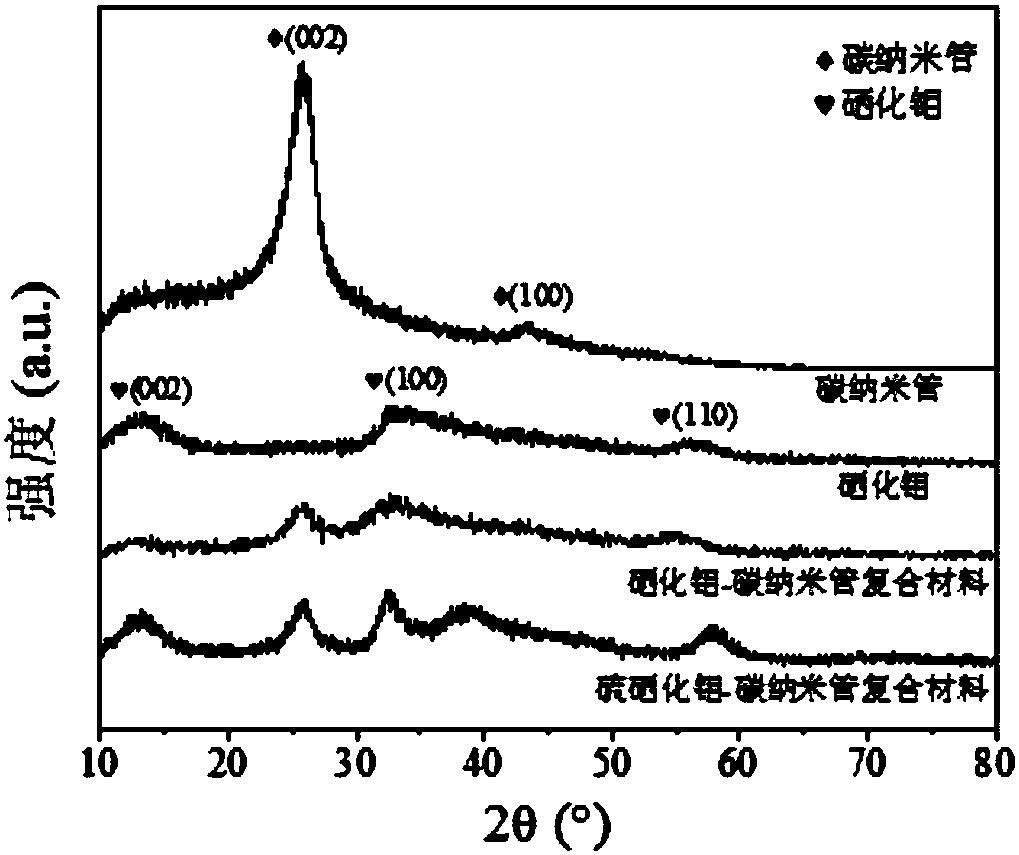

A kind of molybdenum sulfoselenide/carbon nanotube composite material and its preparation and application

A technology of carbon nanotubes and composite materials, used in the preparation/purification of carbon, hybrid capacitor electrodes, structural parts, etc., can solve the problems of poor semiconductor conductivity, limited applications, etc. Excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Disperse 3 g of carbon nanotubes in 100 mL of concentrated sulfuric acid-concentrated nitric acid (volume ratio: 2:1) mixed solution, stir and react at 80° C. for 8 hours to obtain a mixed acid solution of acid-treated carbon nanotubes;

[0047] (2) After the carbon nanotube mixed acid solution is cooled to room temperature, it is centrifuged, washed twice with deionized water and ethanol, and dried in a vacuum oven at 50° C. to obtain acid-treated carbon nanotube powder;

[0048] (3) Dispersing 50 mg of acid-treated carbon nanotube powder in 25 mL of N,N-dimethylformamide, and ultrasonicating for a period of time to obtain an organic dispersion of carbon nanotubes;

[0049] (4) Dissolve 50mg of selenium powder in 25mL of hydrazine hydrate, stir for a period of time to make it evenly dispersed;

[0050] (5) Dissolve 76.61mg of sodium molybdate in 0.2mL of water, and ultrasonically dissolve it to make it evenly dispersed;

[0051] (6) Pour the mixed solution contain...

Embodiment 2

[0055] (1) Disperse 3 g of carbon nanotubes in 100 mL of concentrated sulfuric acid-concentrated nitric acid (volume ratio: 2:1) mixed solution, stir and react at 80° C. for 8 hours to obtain a mixed acid solution of acid-treated carbon nanotubes;

[0056] (2) After the carbon nanotube mixed acid solution is cooled to room temperature, it is centrifuged, washed twice with deionized water and ethanol, and dried in a vacuum oven at 50° C. to obtain acid-treated carbon nanotube powder;

[0057] (3) Dispersing 50 mg of acid-treated carbon nanotube powder in 25 mL of N,N-dimethylformamide, and ultrasonicating for a period of time to obtain an organic dispersion of carbon nanotubes;

[0058] (4) Dissolve 50mg of selenium powder in 25mL of hydrazine hydrate, stir for a period of time to make it evenly dispersed;

[0059] (5) Dissolve 76.61mg of sodium molybdate in 0.2mL of water, and ultrasonically dissolve it to make it evenly dispersed;

[0060] (6) Pour the mixed solution contain...

Embodiment 3

[0064] (1) Disperse 3 g of carbon nanotubes in 100 mL of concentrated sulfuric acid-concentrated nitric acid (volume ratio: 2:1) mixed solution, stir and react at 80° C. for 8 hours to obtain a mixed acid solution of acid-treated carbon nanotubes;

[0065] (2) After the carbon nanotube mixed acid solution is cooled to room temperature, it is centrifuged, washed twice with deionized water and ethanol, and dried in a vacuum oven at 50° C. to obtain acid-treated carbon nanotube powder;

[0066] (3) Dispersing 50 mg of acid-treated carbon nanotube powder in 25 mL of N,N-dimethylformamide, and ultrasonicating for a period of time to obtain an organic dispersion of carbon nanotubes;

[0067] (4) Dissolve 50mg of selenium powder in 25mL of hydrazine hydrate, stir for a period of time to make it evenly dispersed;

[0068] (5) Dissolve 76.61mg of sodium molybdate in 0.2mL of water, and ultrasonically dissolve it to make it evenly dispersed;

[0069] (6) Pour the mixed solution contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com