Testing method for performance of photocatalytic air-purifying material

A technology for air purification materials and testing methods, which is applied in material separation, analysis materials, measurement devices, etc., can solve the problems of difficulty in rapid and accurate evaluation of the performance of photocatalytic air purification materials, and achieves the promotion of practical application process, short test period, and test results. Accurate and reliable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

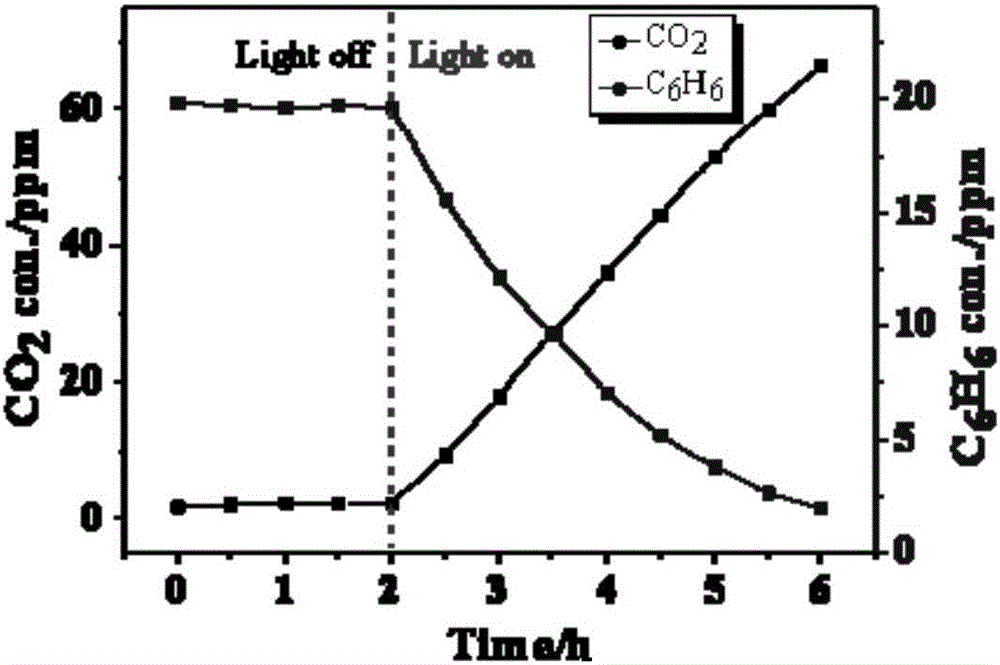

[0037] N-TiO 2 Performance characterization of powder photocatalytic degradation of benzene.

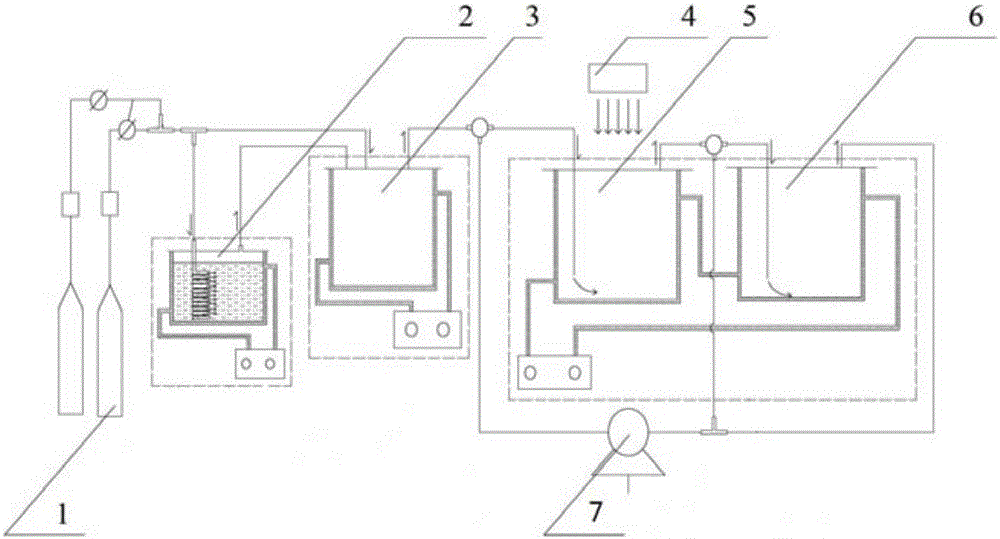

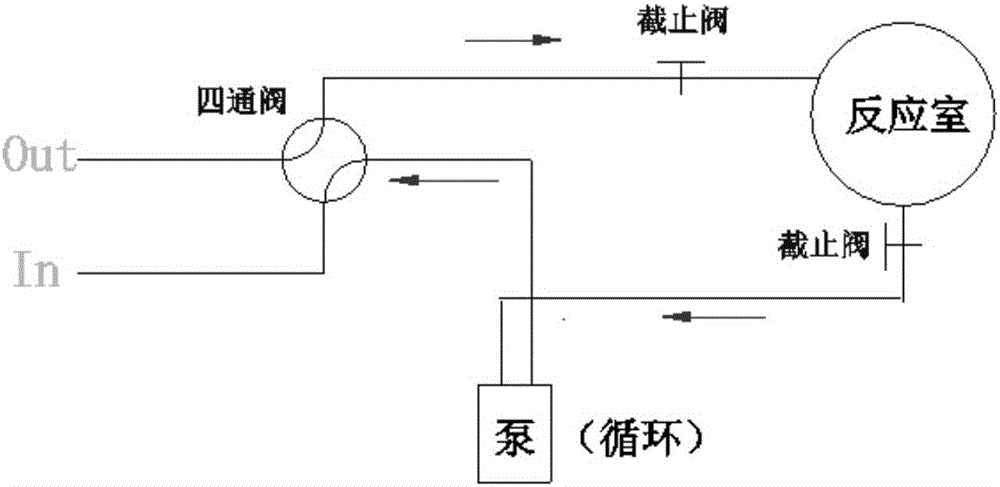

[0038] N-TiO was sprayed with a high-pressure spray gun 2 The dispersion was sprayed on the surface of a 5cm×5cm ground glass sample, weighed after drying with a hair dryer, and the fixed sample load was 30mg. Put the prepared sample into the middle of the bottom of the reaction chamber 5, tighten and close the reaction chamber cover, open the oxygen cylinder valve in the gas source 1 and the two-way ball valves at the front and rear of the reaction chamber, replace the air in the reaction chamber with oxygen, and then close the front and rear valves , turn on the 185nm ultraviolet lamp in the light source system 4 to irradiate the test sample for 6 hours for pretreatment, then use the vacuum pump to evacuate the reaction chamber 5 to -0.10MPa, turn on the gas source 1 and fill the benzene gas with a concentration of 50ppm to 0MPa, and control the target in the reaction chamber The...

Embodiment 2

[0040] N-TiO 2 Performance characterization of spray photocatalytic degradation of toluene, combined with examples figure 1 shown.

[0041] N-TiO was sprayed with a high-pressure spray gun 2 The spray was sprayed on the surface of 5cm×5cm ceramic sheet, dried with a hair dryer, weighed, and the fixed sample load was 10mg. Put the prepared sample into the middle of the bottom of the reaction chamber 4, tighten and close the reaction chamber cover, open the valve of the oxygen cylinder in the gas source 1 and the two-way ball valves at the front and rear of the reaction chamber, replace the air in the reaction chamber with oxygen, and then close the front and rear valves , turn on the 254nm ultraviolet lamp in the light source system to irradiate the test sample for 12 hours for pretreatment, then use a vacuum pump to evacuate the reaction chamber to -0.10MPa, turn on the gas source 1 and fill it with toluene gas with a concentration of 30ppm to -0.05MPa, and then fill it with...

Embodiment 3

[0043] N-TiO 2 Performance characterization of spray photocatalytic degradation of acetaldehyde, combined with examples figure 1 shown.

[0044] The N-TiO 2 The spray was loaded on the surface of 5cm×5cm aluminum-plastic panel, dried with a hair dryer and weighed, and the fixed sample load was 20mg. Put the prepared sample into the middle of the bottom of the reaction chamber 4, tighten and close the reaction chamber cover, open the valve of the oxygen cylinder in the gas source 1 and the two-way ball valves at the front and rear of the reaction chamber, replace the air in the reaction chamber with oxygen, and then close the front and rear valves , turn on the 365nm ultraviolet lamp in the light source system to irradiate the test sample for 24 hours for pretreatment, then use a vacuum pump to evacuate the reaction chamber to -0.10MPa, turn on the gas source 1 and fill the acetaldehyde gas with a concentration of 1ppm to -0.09MPa, and fill it with high-purity Nitrogen to 0M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com