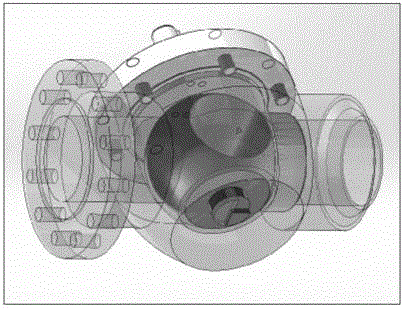

Forced seal ball valve

A technology of forced sealing and ball valves, applied in the direction of valve devices, cocks including cut-off devices, engine components, etc., can solve the problems of large structure and volume, insufficient normal sealing force of valve seats, and the influence of turbulent flow on valve ball components, etc. , to achieve the effect of smooth and reliable transmission, rapid switching action, uniform and reliable cohesion force of forced sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

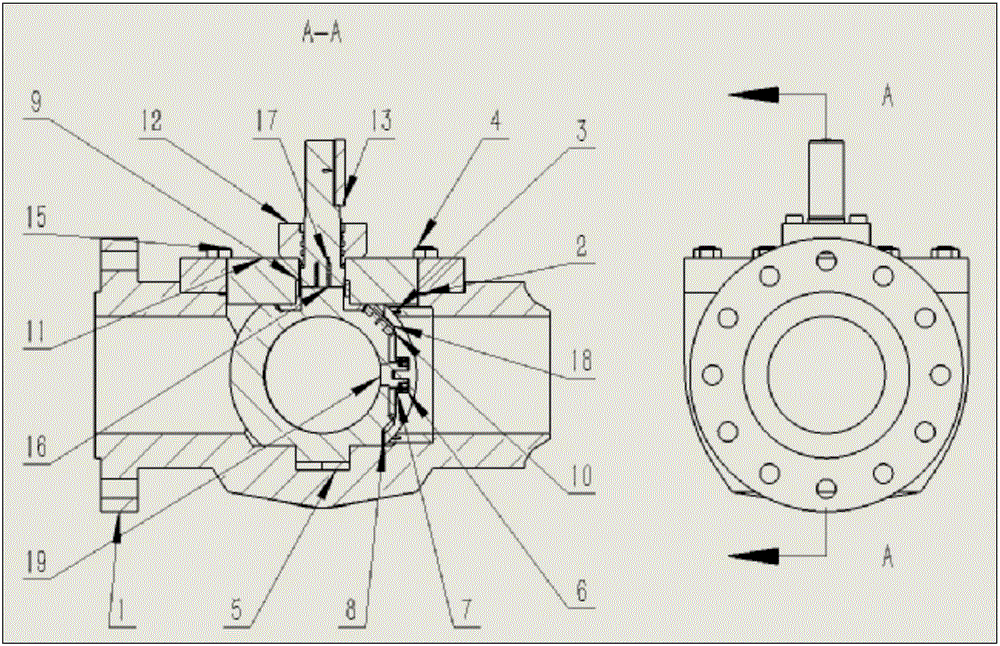

[0049] The forced sealing valve of the present invention can be implemented in various valve body structures such as side-mounted, top-mounted or fully welded. Here, the top-loading type is used as an example to illustrate.

[0050] The top-loading valve body (1) and the upper cover (11) are manufactured by a mature casting process. Later, after machining, the parts meet the assembly size. The rest of the metal parts will be forgings. After machining in the later stage, the parts meet the assembly requirements (so there is no processing difficulty in the parts, and some parts can directly use the same standard parts, such as: bolts, nuts, screws, etc.).

[0051] The following highlights the assembly process:

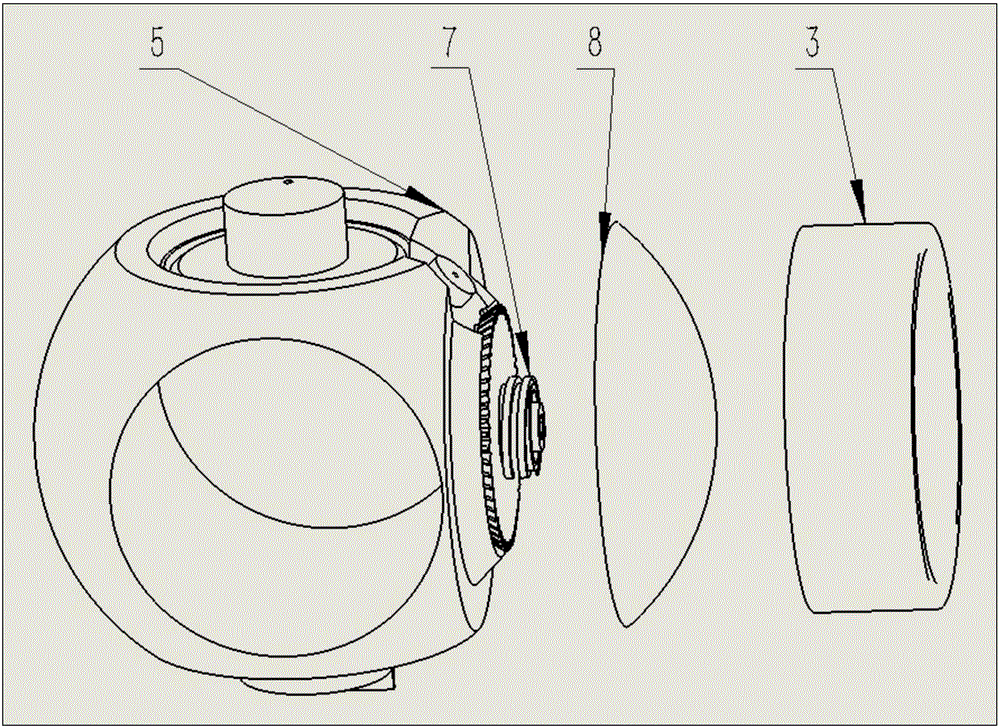

[0052] 1. Assembly of valve seat (3) ( Figure 9 ):

[0053] The valve seat (3) can be directly pressed into the reserved position of the top-mounted valve body with an interference fit, such as Figure 7 shown. The sealing between the valve seat and the valve bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com