Anti-sliding self-locking universal bearing

A self-locking and bearing technology, applied in the field of bearings, can solve problems such as difficulty in ensuring stable operation of workpieces and easy slippage of bearings, and achieve the effects of ensuring long-term effective operation, improving balance, and increasing friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below in conjunction with the accompanying drawings.

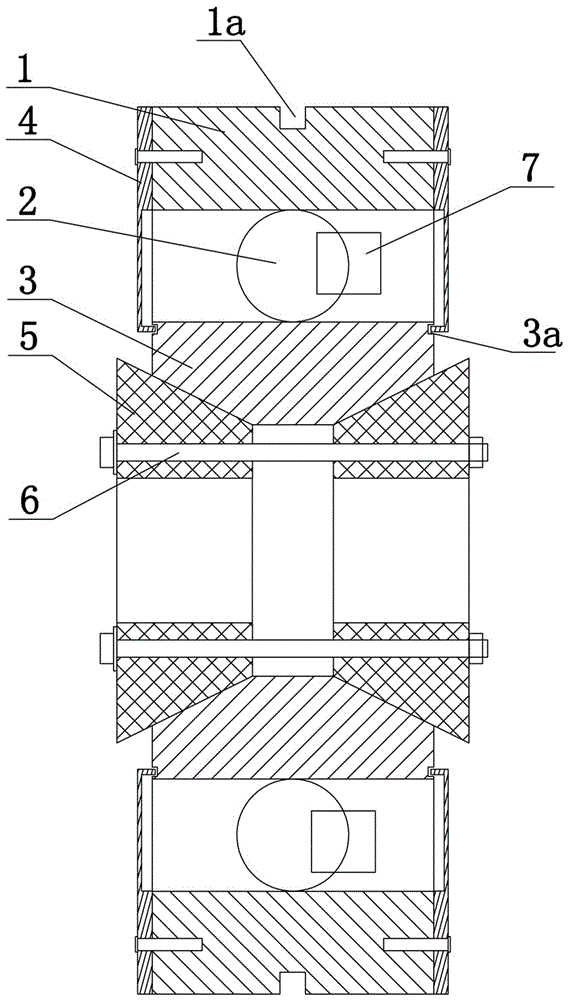

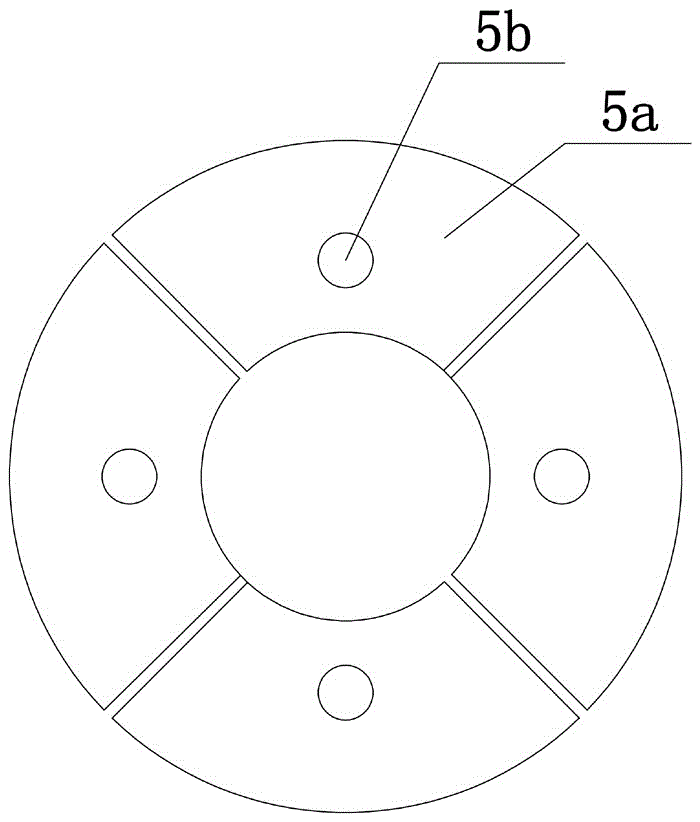

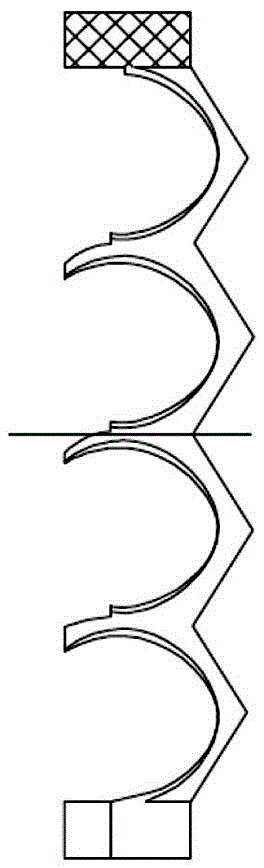

[0023] A non-slip self-locking universal bearing, comprising an outer ring 1, a rolling element 2, an inner ring 3, a dust cover 4, a conical ring 5 and a cage 7; The axis is set, and the rolling element 2 is sandwiched between the inner ring 3 and the outer ring 1; the dust cover 4 is fixed on both sides of the outer ring 1, and the dust cover 4 extends inward and is embedded in the inner ring 3 Side wall; the conical ring 5 has a pair, which are respectively arranged on both sides of the inner wall of the inner ring 3; the pair of conical rings 5 are fixedly connected by bolts 6; the rolling element 2 is embedded in the cage 7; the back of the cage 4 is provided with an opening The window hole, and the open window hole has a self-locking amount.

[0024] The setting of the self-locking amount ensures the consistency of the linear velocity of the groove w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com