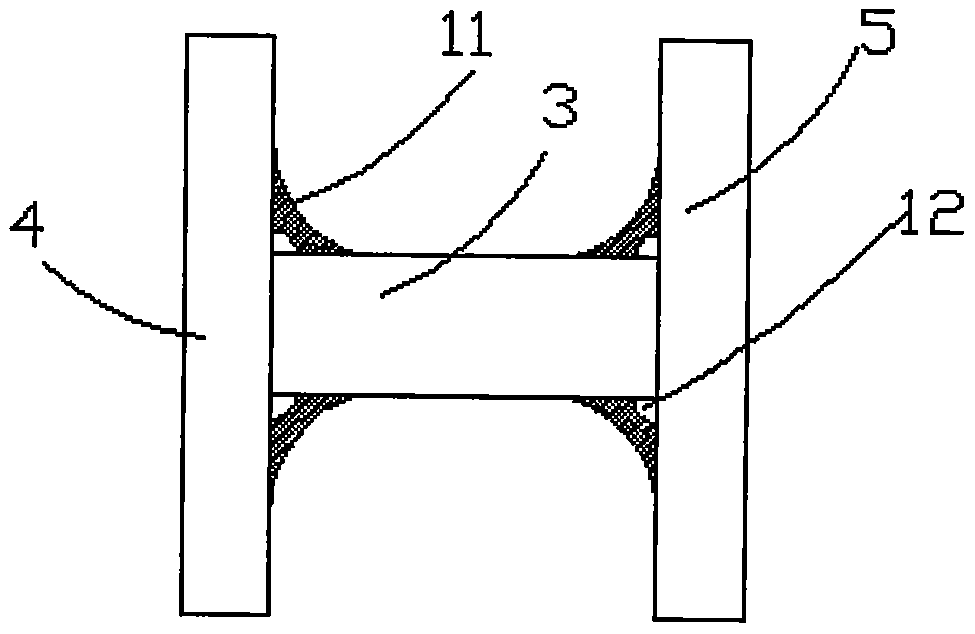

H-shaped steel structural column provided with base for dwelling houses and alloy material for manufacturing same

A technology of alloy materials and steel structures, which is applied in the field of alloy materials of I-shaped steel structural columns and I-shaped steel structural columns, can solve the problems of no steel structure products, increased corrosion, and shortened service life of steel structures, so as to increase anti-corrosion performance, The effect of improving performance and improving structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0071] An alloy material used to manufacture I-shaped steel structural columns with bases for residential buildings, comprising the following components by weight ratio:

[0072] Iron content at 90%;

[0073] The content of manganese oxide is 1%;

[0074] The content of magnesium oxide is 0.3%;

[0075] Aluminum content is 0.5%;

[0076] The content of zinc oxide is 1%;

[0077] Lithium oxide content is 0.7%;

[0078] Titanium oxide content is 1.5%;

[0079] Potassium oxide content is 1%;

[0080] The content of nanometer graphite is 4%.

[0081] The strength of the overall structure of the steel structure obtained from the above formula is improved, and the support force that can bear the outside is significantly improved. Compared with the common steel structure in the existing market, it is known. In addition, the oxidized metal elements added in the present invention can play an anti-oxidation effect and delay the time of corrosion and rust, and meanwhile, the incre...

Embodiment 2

[0083] An alloy material used to manufacture I-shaped steel structural columns with bases for residential buildings, comprising the following components by weight ratio:

[0084] Iron content at 83%;

[0085] The content of manganese oxide is 1.5%;

[0086] The content of magnesium oxide is 2%;

[0087] Aluminum content is 1%;

[0088] The content of zinc oxide is 2%;

[0089] Lithium oxide content is 3%;

[0090] Titanium oxide content is 1.5%;

[0091] Potassium oxide content is 1%;

[0092] Nanographite content is 5%.

[0093] The strength of the overall structure of the steel structure obtained from the above formula is improved, and the support force that can bear the outside is significantly improved. Compared with the common steel structure in the existing market, it is known. In addition, the oxidized metal elements added in the present invention can play an anti-oxidation effect and delay the time of corrosion and rust, and meanwhile, the increase of graphite c...

Embodiment 3

[0095] An alloy material used to manufacture I-shaped steel structural columns with bases for residential buildings, comprising the following components by weight ratio:

[0096] Iron content at 86%;

[0097] The content of manganese oxide is 1.5%;

[0098] The content of magnesium oxide is 1.5%;

[0099] Aluminum content is 1%;

[0100] The content of zinc oxide is 2%;

[0101] Lithium oxide content is 2.5%;

[0102] Titanium oxide content is 1.5%;

[0103] Potassium oxide content is 1%;

[0104] The content of nano graphite is 3%.

[0105] The strength of the overall structure of the steel structure obtained from the above formula is improved, and the support force that can bear the outside is significantly improved. Compared with the common steel structure in the existing market, it is known. In addition, the oxidized metal element added in the present invention can play an anti-oxidation effect and delay the time of corrosion and rust, and meanwhile, the reduction o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com