A prefabricated large block assembled concrete drainage pipe base and its construction method

A technology of prefabricated concrete and drainage pipes, which is applied in infrastructure engineering, construction, etc., can solve the problems of affecting traffic, the bottom of the groove is easily soaked in water, and the bottom of the groove is easy to be frozen, so as to ensure social traffic and personal safety. And the effect of novel and simple structure, undisturbed soil and less environmental disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

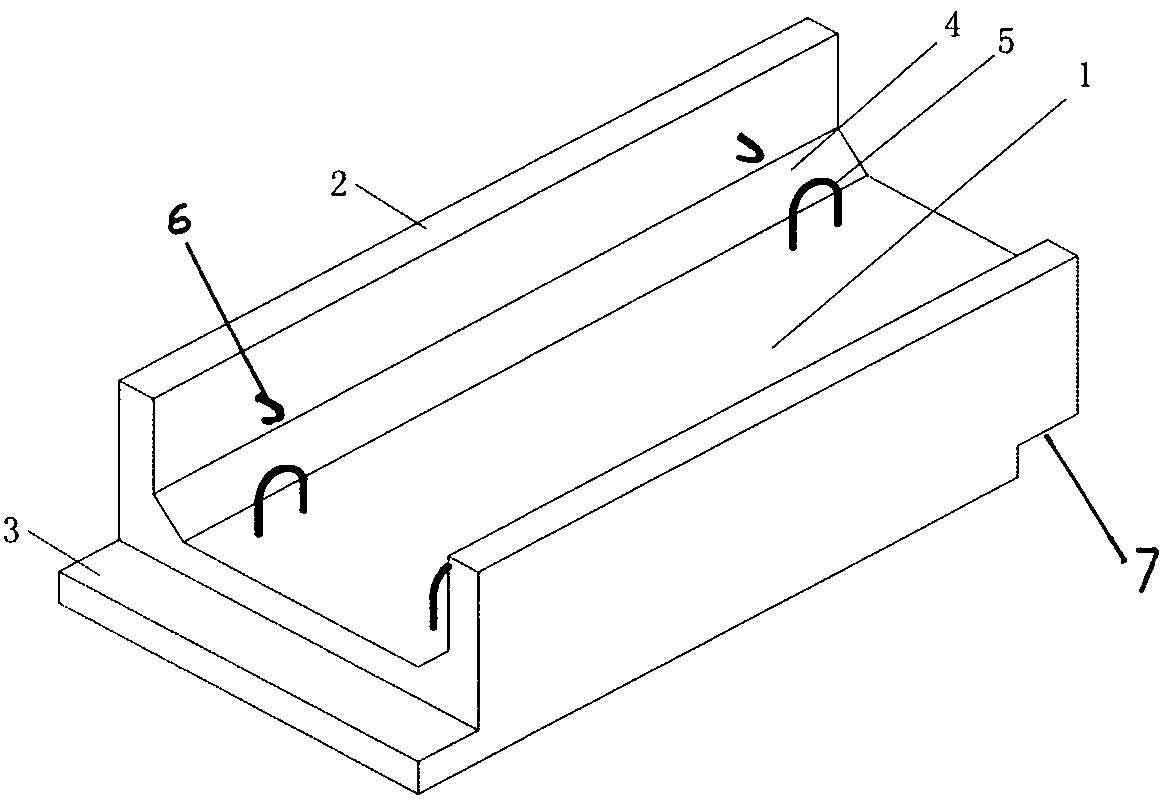

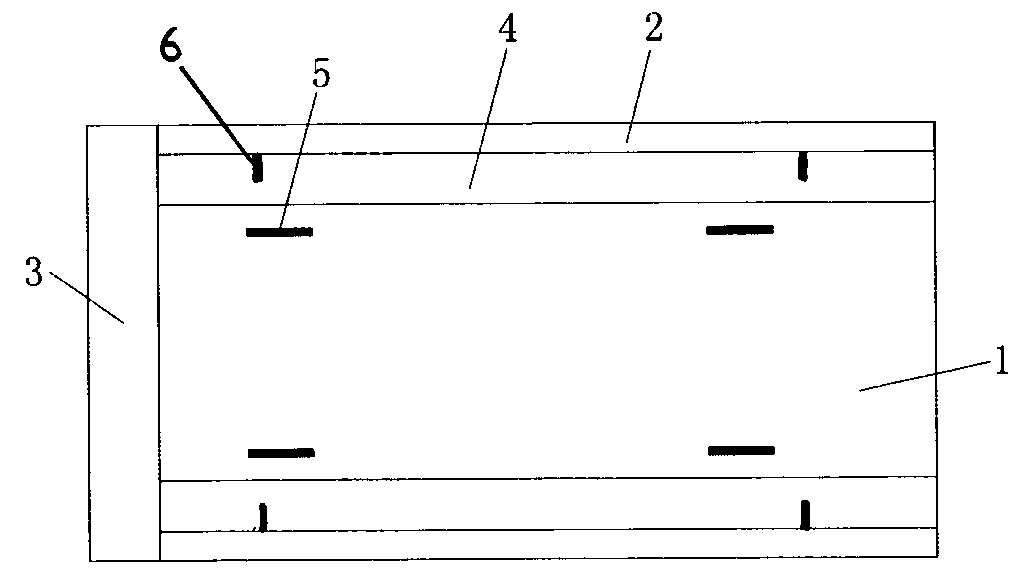

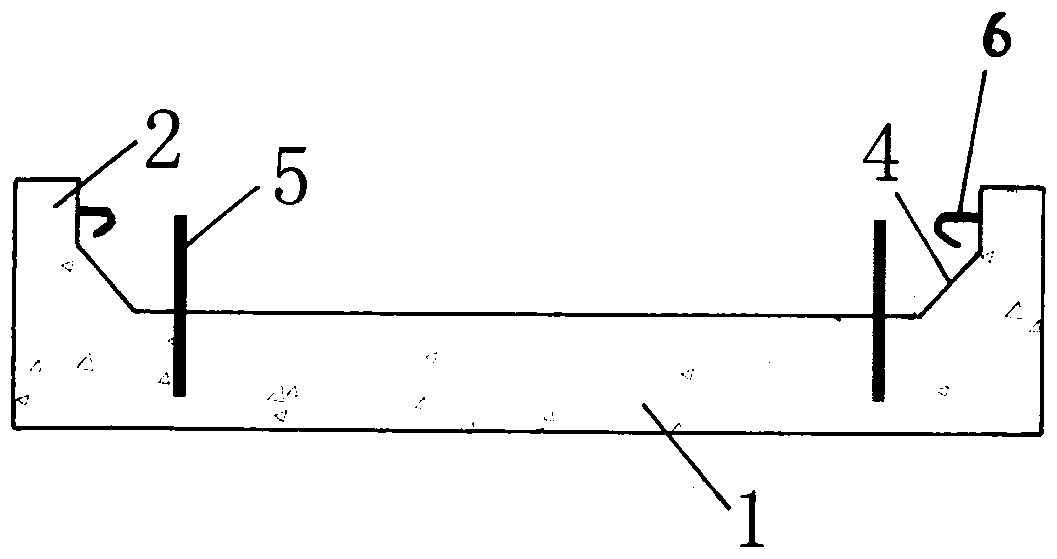

[0021] Such as Figure 1 to Figure 3 As shown, a prefabricated large-scale block-assembled concrete drainage pipe base and its construction method include the following steps:

[0022] (1) Prefabricated concrete drainage pipe base. According to the diameter of the pipe to be installed, the standard specification of the concrete drainage pipe base is designed. Molds are designed based on standard dimensions for concrete drainage pipe foundations. The concrete drainage pipe base is manufactured in the processing plant according to the designed standard size and mold.

[0023] The concrete drainage pipe base includes a plate body 1 and a hook 5 . The plate body is concave. The lower part of the front end of the plate body is provided with an outer convex edge 3 protruding from the front end surface of the plate body. The lower part of the rear end of the board is provided with a concave edge 7 recessed into the rear end surface of the board. The concave edge of the rear end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com