Elastic artificial leather and production method therefor

一种伸缩性、人造革的技术,应用在加压缩水、纺织品和造纸、运输和包装等方向,能够解决未公开改善伸长性及伸缩性的人造革、未公开改善人造革纵向伸长性、伸缩性的简便且有效的方法等问题,达到兼备充实感、形态稳定性优异、兼备手感的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

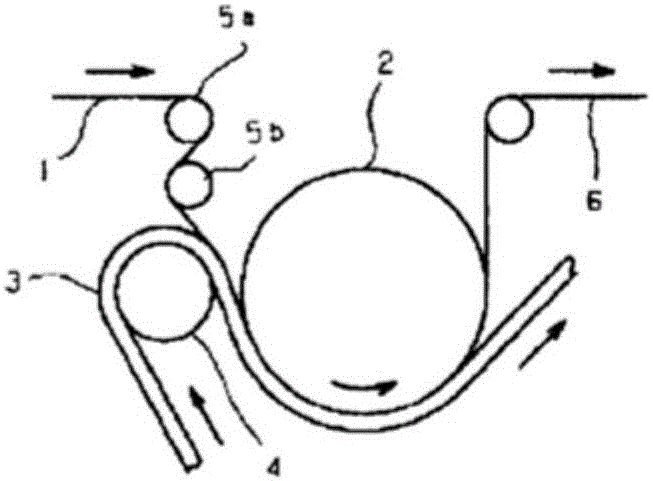

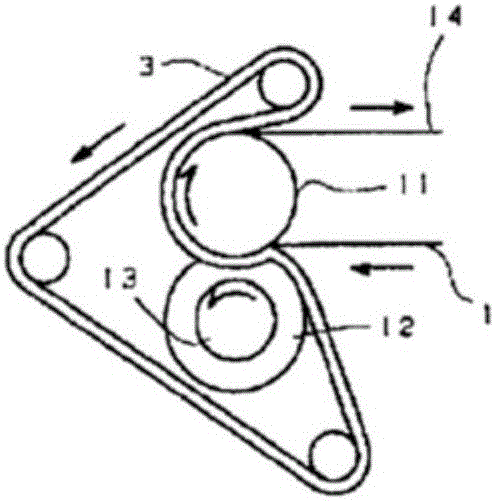

[0167] The stretchable artificial leather according to the first embodiment of the present invention is a stretchable artificial leather composed of a fiber entanglement body including ultrafine fibers having an average single fiber fineness of 0.9 decitex or less, and the apparent density thereof is set to 0.40 g / cm 3 above, and if Figure 4 , 5 As shown, in a section parallel to its thickness direction and longitudinal direction, there is a micro-corrugated structure composed of ultrafine fibers along the longitudinal direction. The stretchable artificial leather of the present invention has moderate stretchability and sense of end of elongation in the longitudinal direction due to its relatively high apparent density and micro-corrugated structure, and at the same time has good mechanical properties. The stretchable artificial leather of the present embodiment is preferably produced by the above-mentioned production method of the present invention, but the production metho...

no. 2 approach

[0194] The stretchable artificial leather of the second embodiment can be produced, for example, by the above-mentioned production method, and has the following features. Hereinafter, the stretchable artificial leather of the second embodiment will be described in detail, and the configurations not particularly mentioned are the same as those of the stretchable artificial leather of the first embodiment.

[0195] [elasticity artificial leather]

[0196] The stretchable artificial leather of the second embodiment is a stretchable artificial leather composed of a fiber entanglement body containing ultrafine fibers having an average single fiber fineness of 0.9 decitex or less, and the apparent density thereof is set to 0.40 g / cm 3 In addition, the elongation coefficient calculated by the following formula (1) shall be 50 or less. The stretchable artificial leather of the present embodiment has moderate stretchability in the longitudinal direction and a feeling of end-of-stretch...

no. 3 approach

[0209] [elasticity artificial leather]

[0210] The stretchable artificial leather of the third embodiment in the present invention has the following features.

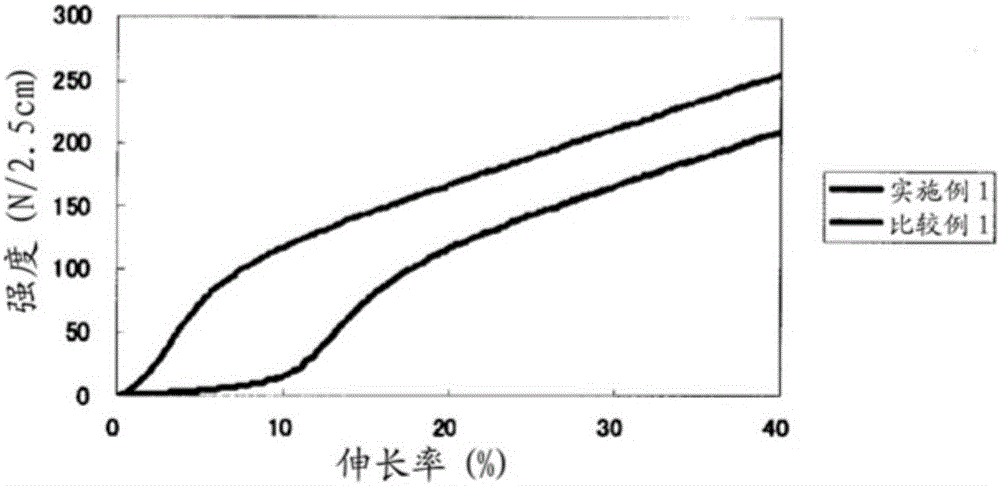

[0211] The stretchable artificial leather of the present embodiment has stretchability, and has the following (A) and (B) in the longitudinal strength-elongation curve measured by the method described in JIS L 1096 (1999) 8.14.1A method conditions of.

[0212] (A) Strength F at 5% elongation 5% It is 0.1~10N / 2.5cm.

[0213] (B) Strength F at 20% elongation 20% and the above F 5% In the relationship, F 20% / F 5% 5 or more.

[0214] In the present embodiment, the strength-elongation curve is measured by the method described in JIS L 1096 (1999) 8.14.1A method. A test piece with a width of 2.5 cm was fixed to chucks with a clamp interval of 20 cm, and the test piece was pulled at a constant speed to obtain elongation and strength. Based on the results, a strength-elongation curve was prepared in which the abscis...

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear density | aaaaa | aaaaa |

| apparent density | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com