Knitting method of rib style knitted fabric and rib style knitted fabric

A technology of knitted fabrics and ribs, which is applied in the weaving of ribbed knitted fabrics and the field of ribbed knitted fabrics, which can solve the problems of insufficient thickness, difficulty in obtaining thickness, and large thickness, etc., and achieve the effect of good appearance and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

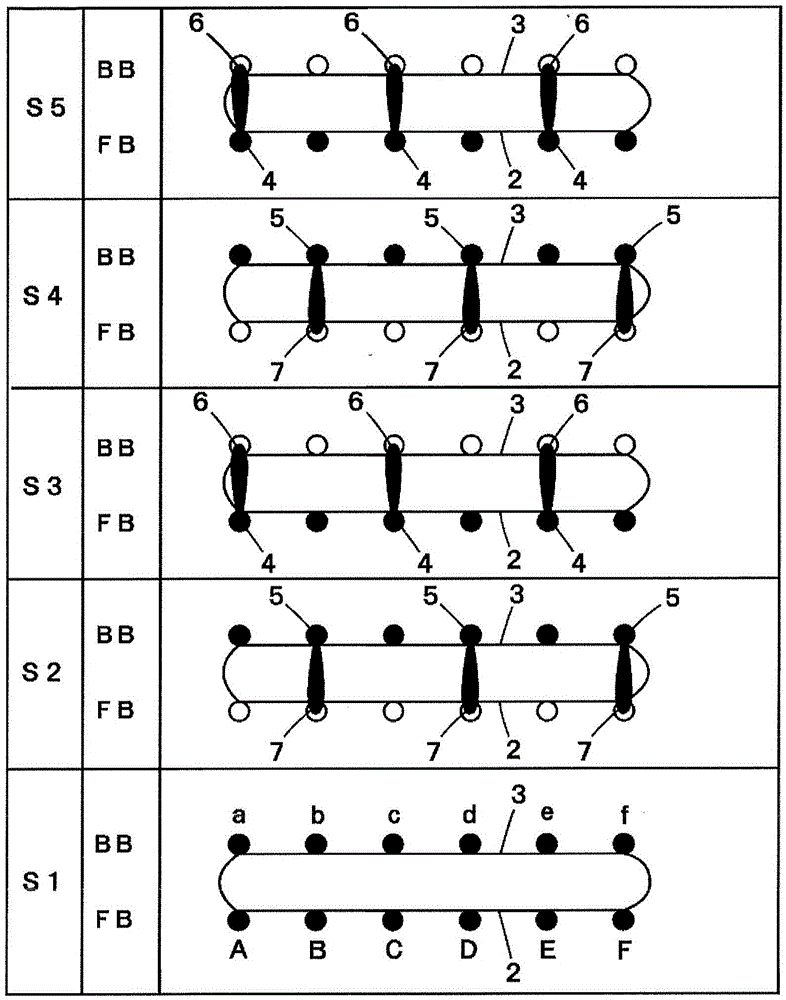

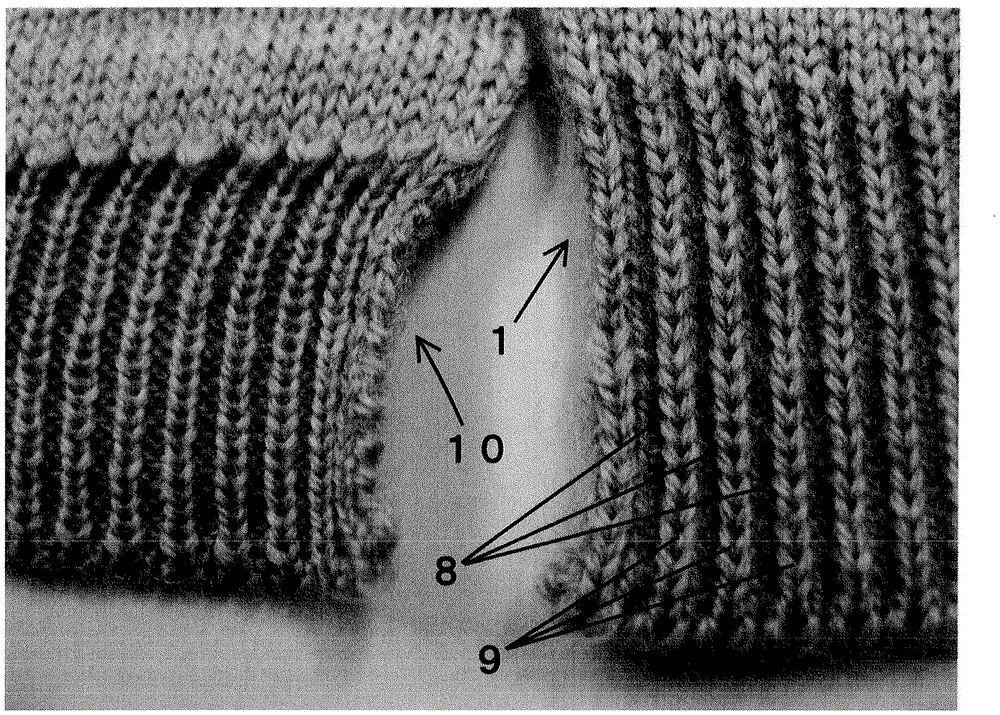

[0025] Below, use figure 1 The knitting process diagram of rib style knitted fabric 1 and figure 2 The image of the rib-style knitted fabric 1 and the image of the conventional rib-style knitted fabric 10 will describe the knitting method of the 1x1 rib-style knitted fabric 1 as an embodiment of the present invention. The flat knitting machine used in this embodiment is a two-needle-bed flat knitting machine having a pair of front and rear needle beds, and knitting is performed by full-needle knitting in which continuous knitting needles do not skip knitting needles. For the convenience of illustration, the ratio of the number of knitting needles in the knitting process diagram figure 2 The ribbed style knit on the right side of the photo is 1 less. figure 1 In , the numbers on the left side of the figure indicate the weaving step (S). FB represents the front needle bed, and BB represents the rear needle bed. The uppercase letters A to F represent the knitting needles of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com