Bearing steel wire rod and production method thereof

A production method and bearing steel technology, applied in the field of iron and steel material production, can solve the problems of inability to mass production, difficult to achieve technology, harsh conditions, etc., and achieve the effect of avoiding abnormal structure and shortening spheroidizing annealing time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

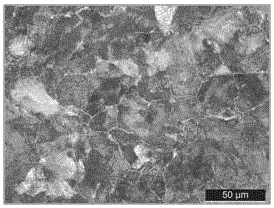

Embodiment 1

[0039] Smelting molten steel and continuous casting into billets, the weight percentages of steel components are: C 0.95%, Si 0.28%, Mn 0.31%, Cr 1.60%, P 0.025%, S 0.018%, Mo 0.08%, Ni 0.13%, Cu 0.20% , O 0.0011%, the balance is Fe and trace impurities.

[0040] The molten steel is refined in a RH furnace, the vacuum degree is 91Pa, and the vacuum cycle treatment time is 46 minutes to ensure that the hydrogen content is less than 3ppm.

[0041] The continuous casting adopts electromagnetic stirring and light reduction process, the superheat degree of the tundish is 15℃, and the carbon segregation index in the center of the billet is 1.03. After the continuous casting of the continuous casting billet is completed, it enters the slow cooling pit for slow cooling for 72 hours.

[0042] The billet was heated to 1150°C and held for 100 minutes.

[0043] The steel billet after dephosphorization is subjected to 6+8 passes of roughing and intermediate rolling, 4 passes of pre-finis...

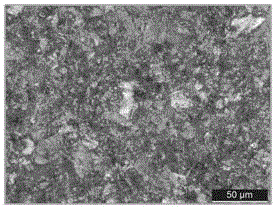

Embodiment 2

[0046]Smelting molten steel and continuous casting into billets, the weight percentages of steel components are: C 1.05%, Si 0.25%, Mn 0.25%, Cr 1.65%, P 0.018%, S 0.025%, Mo 0.10%, Ni 0.10%, Cu 0.25% , O 0.0010%, the balance is Fe and trace impurities.

[0047] The molten steel is refined in a RH furnace with a vacuum degree of 70Pa and a vacuum cycle treatment time of 38 minutes to ensure that the hydrogen content is less than 3ppm.

[0048] The continuous casting adopts electromagnetic stirring and light reduction process, the superheat degree of the tundish is 18℃, and the carbon segregation index in the center of the billet is 1.02. After the continuous casting of the continuous casting billet is completed, it enters the slow cooling pit for slow cooling for 74 hours.

[0049] The billet was heated to 1150°C and held for 105 minutes.

[0050] The billet after dephosphorization is subjected to 6+8 passes of roughing and intermediate rolling, 4 passes of pre-finishing rol...

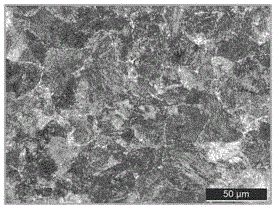

Embodiment 3

[0053] Smelting molten steel and continuous casting into billets, the weight percentages of steel components are: C 1.00%, Si 0.35%, Mn 0.40%, Cr 1.55%, P 0.017%, S 0.020%, Mo 0.05%, Ni 0.15%, Cu 0.15% , O 0.0008%, the balance is Fe and trace impurities.

[0054] The molten steel is refined in a RH furnace with a vacuum degree of 80Pa and a vacuum cycle treatment time of 42 minutes to ensure that the hydrogen content is less than 3ppm.

[0055] The continuous casting adopts electromagnetic stirring and light reduction process, the superheat degree of the tundish is controlled at 12℃, and the carbon segregation index in the center of the billet is 0.98. After the continuous casting of the continuous casting billet is completed, it enters the slow cooling pit for slow cooling for 75 hours.

[0056] The billet was heated to 1100°C and held for 110 minutes.

[0057] The billet after dephosphorization is subjected to 6+8 passes of roughing and intermediate rolling, 4 passes of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com