Color paste used for preparing whiteboard marker ink and preparation method thereof

A pen ink and color paste technology, applied in the preparation of color paste for whiteboard pen ink and the field of preparation thereof, can solve the problems affecting the writing fluency, color, erasability, coarse pigment particles, low tinting strength of ink, etc. The effect of good rubbing performance, uniform dispersion and pure color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

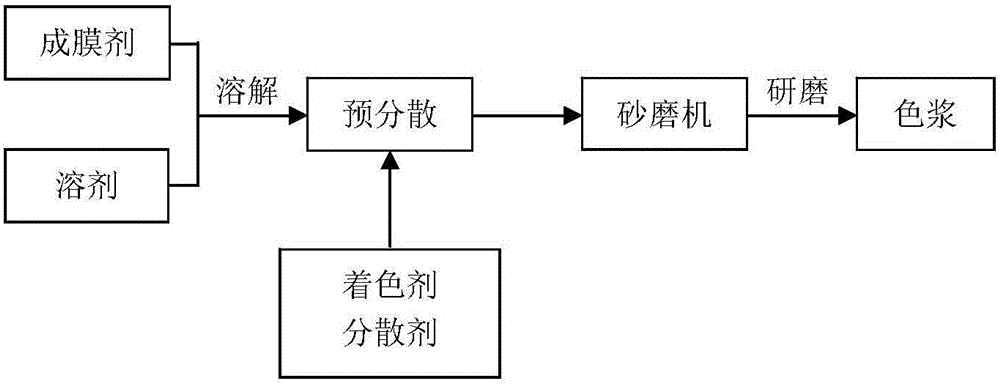

Method used

Image

Examples

Embodiment 1

[0028] This embodiment provides a kind of color paste for preparing whiteboard pen ink. The components include: 60g of solvent, wherein 40g of ethanol, 10g of n-propanol, and 10g of n-butanol; 3g of film-forming agent, which is carboxylate Methyl cellulose; 6 g of colorant, which is carbon black; 1 g of dispersant, which is hyperdispersant Solsperse-24000.

[0029] The above-mentioned preparation method for preparing the color paste of whiteboard pen ink, the steps include: under normal temperature and pressure, add 40g ethanol, 10g n-propanol, 10g n-butanol, 3g carboxymethyl cellulose to the dispersion tank successively, stir at a low speed 20 minutes to completely dissolve carboxymethyl cellulose; then add 6g of carbon black, 1g of hyperdispersant Solsperse-24000, and pre-disperse at low speed for 10 minutes; finally send it to the sand mill and circulate it under the conditions of system pressure 0.02Mpa and material temperature 10℃ Grinding for 5 times, the color paste can...

Embodiment 2

[0032] This embodiment provides a color paste for preparing whiteboard pen ink. The components include: 60g of solvent, including 35g of ethanol and 25g of isopropanol; 5g of film-forming agent, and the film-forming agent is carboxymethyl cellulose; 10g of colorant, the colorant is phthalocyanine blue P.B.15:3; 1g of dispersant, the dispersant is SN-5027.

[0033] The above-mentioned preparation method for preparing the color paste of the whiteboard pen ink, the steps include: under normal temperature and pressure, add 35g ethanol, 25g isopropanol, 5g carboxymethyl cellulose successively to the dispersion bucket, stir at a low speed for 25min to make the carboxymethyl Completely dissolve the cellulose; then add 10g phthalocyanine blue P.B.15:3, 1g dispersant SN-5027, pre-disperse at low speed for 10min; finally send it to the sand mill and grind it circularly under the conditions of system pressure 0.01Mpa and material temperature 20℃ 3 times, the color paste is obtained after...

Embodiment 3

[0036]This embodiment provides a color paste for preparing whiteboard pen ink. The components include: 70g of solvent, including 35g of ethanol, 25g of n-propanol, and 10g of 1,2-propanediol; 6g of film-forming agent, the film-forming agent It is carboxymethyl cellulose; colorant 10g, said colorant is P.R.112; dispersant 2g, said dispersant is hyperdispersant Solsperse-20000.

[0037] The preparation method for the above-mentioned color paste for preparing whiteboard pen ink, the steps include: under normal temperature and pressure, add 35g ethanol, 25g n-propanol, 10g1,2-propanediol, 6g carboxymethyl cellulose successively to the dispersion bucket, and slowly Stir for 20 minutes to completely dissolve carboxymethyl cellulose; then add 10g P.R.112, 2g hyperdispersant Solsperse-20000, and pre-disperse at low speed for 10 minutes; finally send it to a sand mill under the conditions of system pressure 0.13Mpa and material temperature 25°C Circulate grinding 4 times, and get the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com