Preparation method for biological fermentation integrated organic fertilizer

A technology of biological fermentation and organic fertilizer, applied in the preparation of organic fertilizer, biological organic part treatment, organic fertilizer and other directions, can solve problems such as pollution and reduce labor costs, and achieve the effect of improving production speed and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

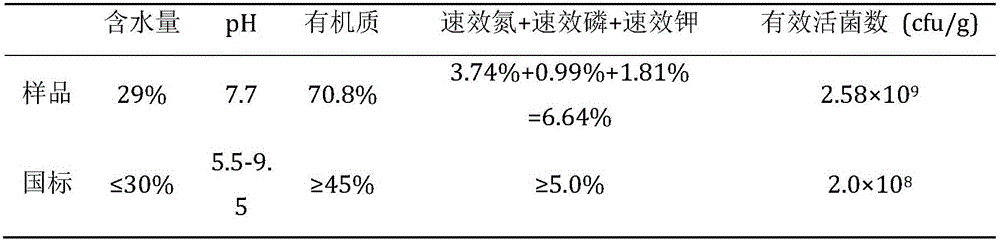

Examples

Embodiment Construction

[0018] This embodiment specifically includes the following steps:

[0019] Step 1. Take the straw waste from the park provided by the Maqiao Base of the Lvrui Vegetable and Fruit Cooperative in Chongming County, Shanghai, pile up the material to 2 / 3 of the height of the fermentation tank, and calculate the required amount of bacteria and auxiliary materials based on this volume.

[0020] For practical application, other straw wastes can be selected and have similar technical effects, such as a mixture of rice straw, asparagus straw and weeds.

[0021] The fermentation auxiliary materials used in this example are urea and compound fertilizer, and the microbial agent used is the compound agent JFB-1.

[0022] Step 2. Take the temperature in the fermentation tank no longer rising or falling as a sign of the completion of a short-term fermentation. Before a new round of fermentation, turn over or add water to ensure sufficient oxygen for microbial growth and metabolism. , to ensu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com