Novel treatment method for leather sewage

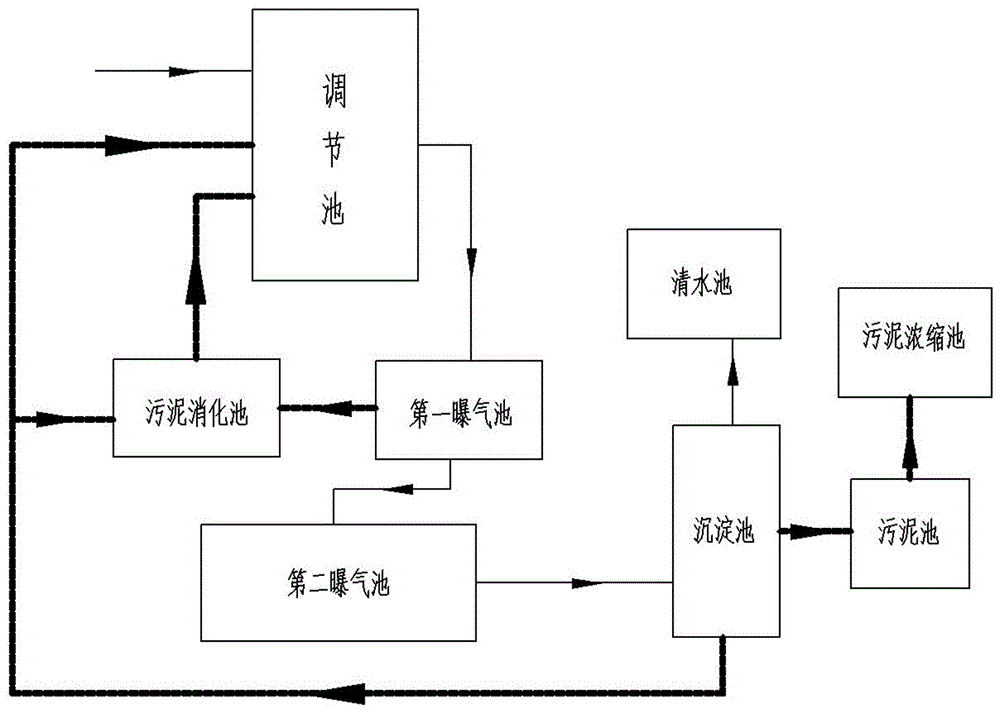

A treatment method and technology for leather sewage, applied in biological water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It can reduce the operating cost, reduce the processing time and improve the processing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Expansion of treated bacteria:

[0044] (a) Add 1 kg of treated bacteria to 9 kg of culture medium for primary expansion to obtain 10 kg of primary expansion medium; the culture medium is an aqueous solution of sugarcane molasses with a mass fraction of 4%; the pH of the culture medium is 5.0; aeration The volume is 70L / min; the culture time is 20 hours;

[0045] (b) Add 10 kg of the first-stage expansion culture solution obtained in step (a) into 90 kg of the culture solution for secondary expansion to obtain 100 kg of the second-level expansion culture solution; the culture medium is an aqueous solution of sugarcane molasses with a mass fraction of 4% ; The pH of the culture solution is 5.0; the ventilation rate is 70L / min; the culture time is 22 hours;

[0046] (c) Add 100kg of the secondary expansion culture solution obtained in step (b) into 100kg of the culture solution for three-level expansion to obtain 200kg of activated bacteria liquid; the culture medium is ...

Embodiment 2

[0056] Expansion of treated bacteria:

[0057] (a) Add 1 kg of treated bacteria to 9 kg of culture solution for primary expansion to obtain 10 kg of primary expansion solution; the culture solution is an aqueous solution of sugarcane molasses with a mass fraction of 6%; the pH of the culture solution is 5.5; aeration The volume is 90L / min; the culture time is 24 hours;

[0058] (b) Add 10 kg of the first-stage expansion culture solution obtained in step (a) into 90 kg of the culture solution for secondary expansion to obtain 100 kg of the second-level expansion culture solution; the culture medium is an aqueous solution of sugarcane molasses with a mass fraction of 6%. ; The pH of the culture solution is 5.5; the ventilation rate is 90L / min; the culture time is 26 hours;

[0059] (c) Add 100kg of the secondary expansion culture solution obtained in step (b) into 100kg of the culture medium for three-level expansion to obtain 200kg of activated bacteria liquid; the culture med...

Embodiment 3

[0069] Expansion of treated bacteria:

[0070] (a) Add 1 kg of treated bacteria to 9 kg of culture medium for primary expansion to obtain 10 kg of primary expansion medium; the culture medium is an aqueous solution of sugarcane molasses with a mass fraction of 5%; the pH of the culture medium is 6.0; The volume is 80L / min; the culture time is 22 hours;

[0071] (b) Add 10 kg of the first-level expansion culture solution obtained in step (a) into 90 kg of the culture medium for second-level expansion to obtain 100 kg of the second-level expansion culture solution; the culture medium is an aqueous solution of sugarcane molasses with a mass fraction of 5% ; The pH of the culture solution is 6.0; the ventilation rate is 80L / min; the culture time is 24 hours;

[0072] (c) Add 100kg of the secondary expansion culture solution obtained in step (b) into 100kg of the culture solution for three-level expansion to obtain 200kg of activated bacteria liquid; the culture medium is an aqueo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com