Woodworking tool for reducing friction coefficient during cutting of woodworking tool and manufacturing method of woodworking tool

A friction coefficient and tool technology, applied in manual woodworking tools, wood processing appliances, manufacturing tools, etc., can solve the problems of easy wear and poor thermal stability of tools, and achieve non-oxidative corrosion resistance, stable performance, and improved work efficiency and service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

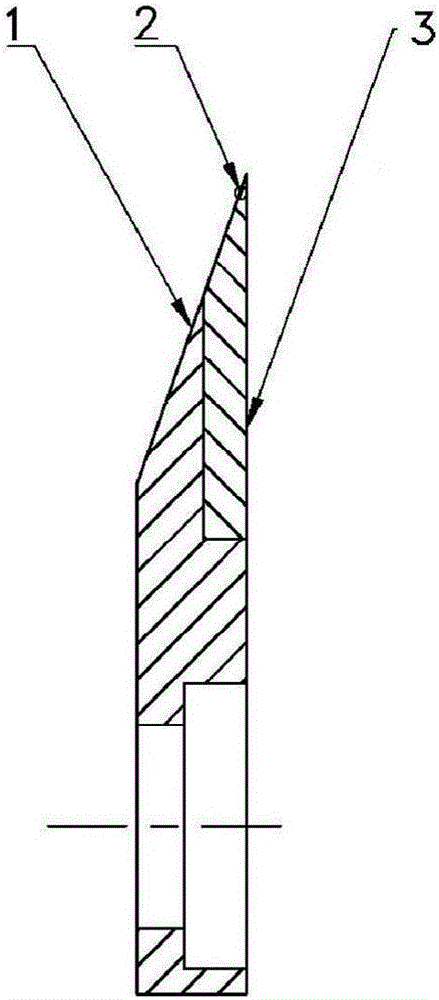

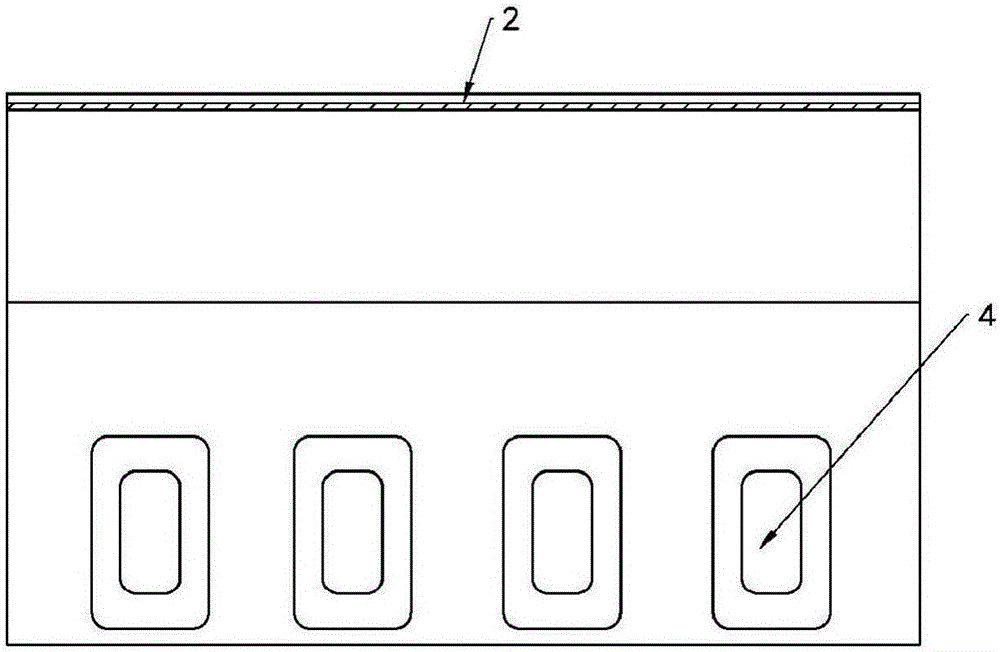

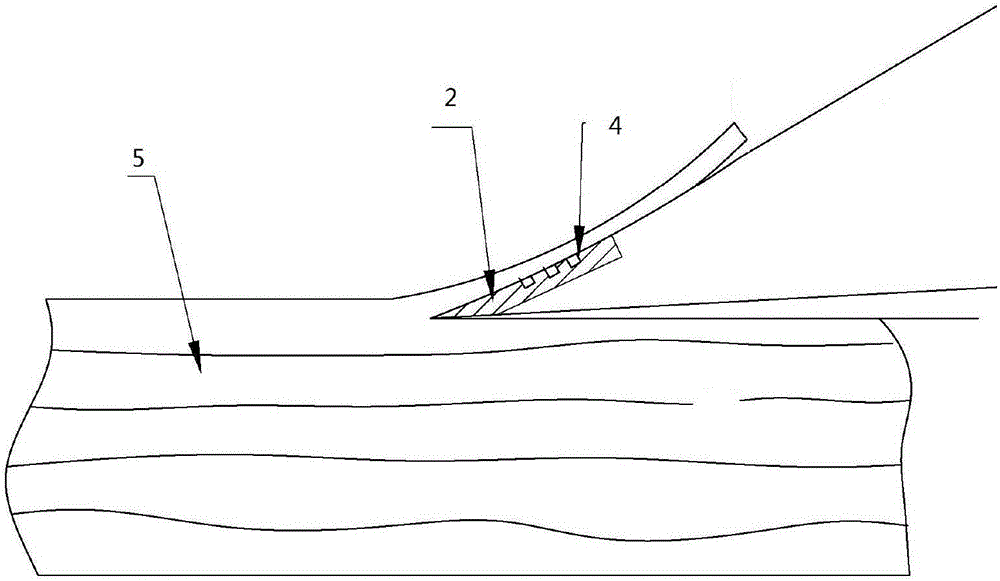

[0027] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0028] In nature, the body surfaces of some insects, snakes, pangolins, sharks and other animals are not completely smooth, and there are tiny structural units with certain geometric shapes randomly or regularly distributed on certain parts of the body surface. The microscopic features of these non-smooth features Surface topography tends to have less frictional resistance than smooth surfaces. Based on the observation of the above phenomenon, the tribology research field proposed the concept of surface microtexture (reference 9: Volchok A, Halperin G, Etsion I. The effect of surface regular microtopography on frettingfatigue life. Wear, 2002, 253 (3 -4):509-515.), the surface micro-texture is a kind of surface functional structure, which is a micron-sca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com