Self-propelled robot used in transformer substation for patrolling and power failure monitoring

A power failure, self-propelled technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of lack of fault classification, unclear responsibility, easy loss, etc., and achieve the effect of saving human resource consumption, reducing work intensity, and increasing battery life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

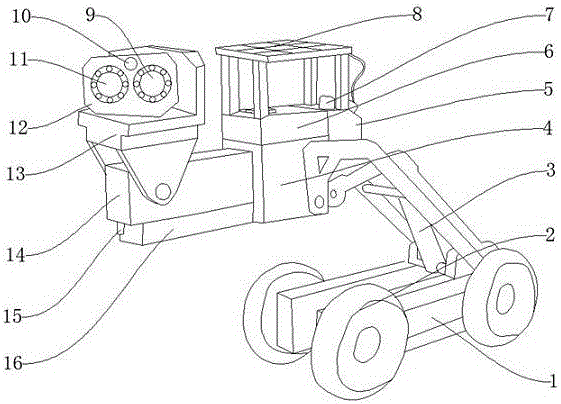

[0014] The present invention will be further explained below in conjunction with the drawings:

[0015] Such as figure 1 As shown, a self-propelled robot for patrolling and monitoring power failures in a substation includes a frame 1 and a motor 4. A drive wheel 2 is provided under the frame 1, and the drive wheel 2 is used to move, and a transmission rod is provided on the drive wheel 2 3. The transmission rod 3 is used to transmit power. A motor 4 is installed on the frame 1, and a water tank 6 is installed on the motor 4 to reduce the temperature of the machine. A battery 5 is installed next to the water tank 6, and the battery 5 is used to store electricity. The battery 5 is provided with a power light 7 which is used to display power. The water tank 6 is provided with a solar panel 8 which is used to collect solar energy. The motor 4 is provided with an oil cylinder 14 and a control box 16 is provided under the oil cylinder 14 A GPS locator 15 is provided next to the contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com