Multifunctional medium-capacity even-dispersion grinding machine and operation method thereof

A technology with uniform capacity and uniform dispersion, applied in grain processing, etc., can solve the problems of poor rotation stability and sealing, low quality of dispersion and grinding, and short service life, so as to ensure working performance, good rotation stability and long service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

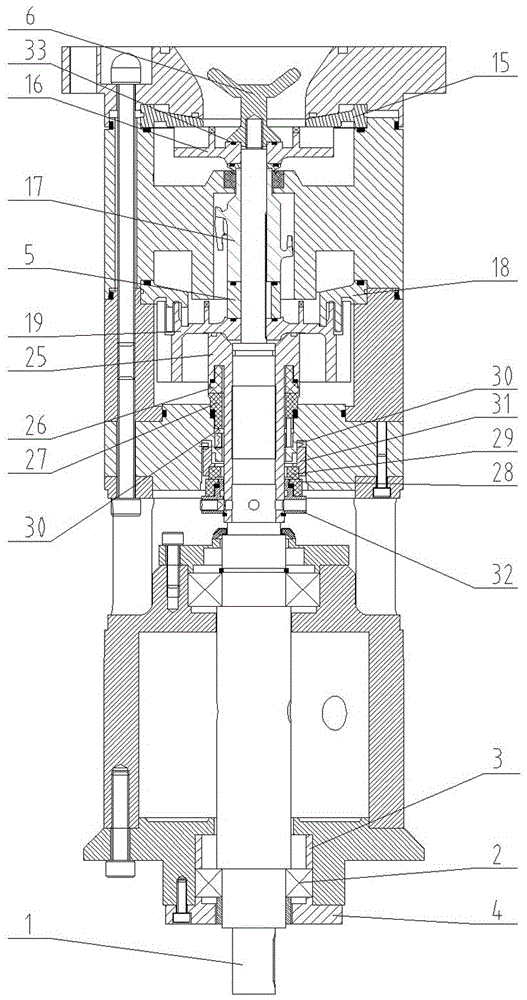

[0029] Such as figure 1 、 figure 2 As shown, a kind of multi-functional middle-capacity uniform dispersing grinder of the present embodiment includes a main shaft 1 , bearing 2 , Bearing retaining ring 3 , Bearing cover 4 , support block 5 , special-shaped nut 6 , bearing base 7 , support cavity 8 , mechanical seal shell 9 , discharge cavity 10 , uniform dispersion chamber 11 , cavity top cover 12 , water inlet 13 , water outlet 14 , Stator 15 , impeller rotor 16 , stirring impeller 17 , grinding stator 18 , grinding rotor 19 , the first entrance 20 , the second entrance 21 , the third entrance 22 , the fourth entrance 23 , exit 24 , machine seal 25 , the first graphite piece 26 , the second graphite piece 27 , the third graphite piece 28 , the fourth graphite piece 29 , spring 30 , shell part 31 , locking cover 32 and sealing ring 33 。

[0030] The connection method of each component is as follows: its m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com