Three pairs of sliding pair-spherical hinge-spherical hinge (3-PSS) mechanism-based coordinate measuring machine

A coordinate measuring machine and parallel technology, which is applied in the field of measuring machines, can solve problems such as the failure of parallel mechanisms to be well applied, the cumulative error of large transferability, and the uneven accuracy of the measurement space, etc. The effect of high system rigidity, light movement and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

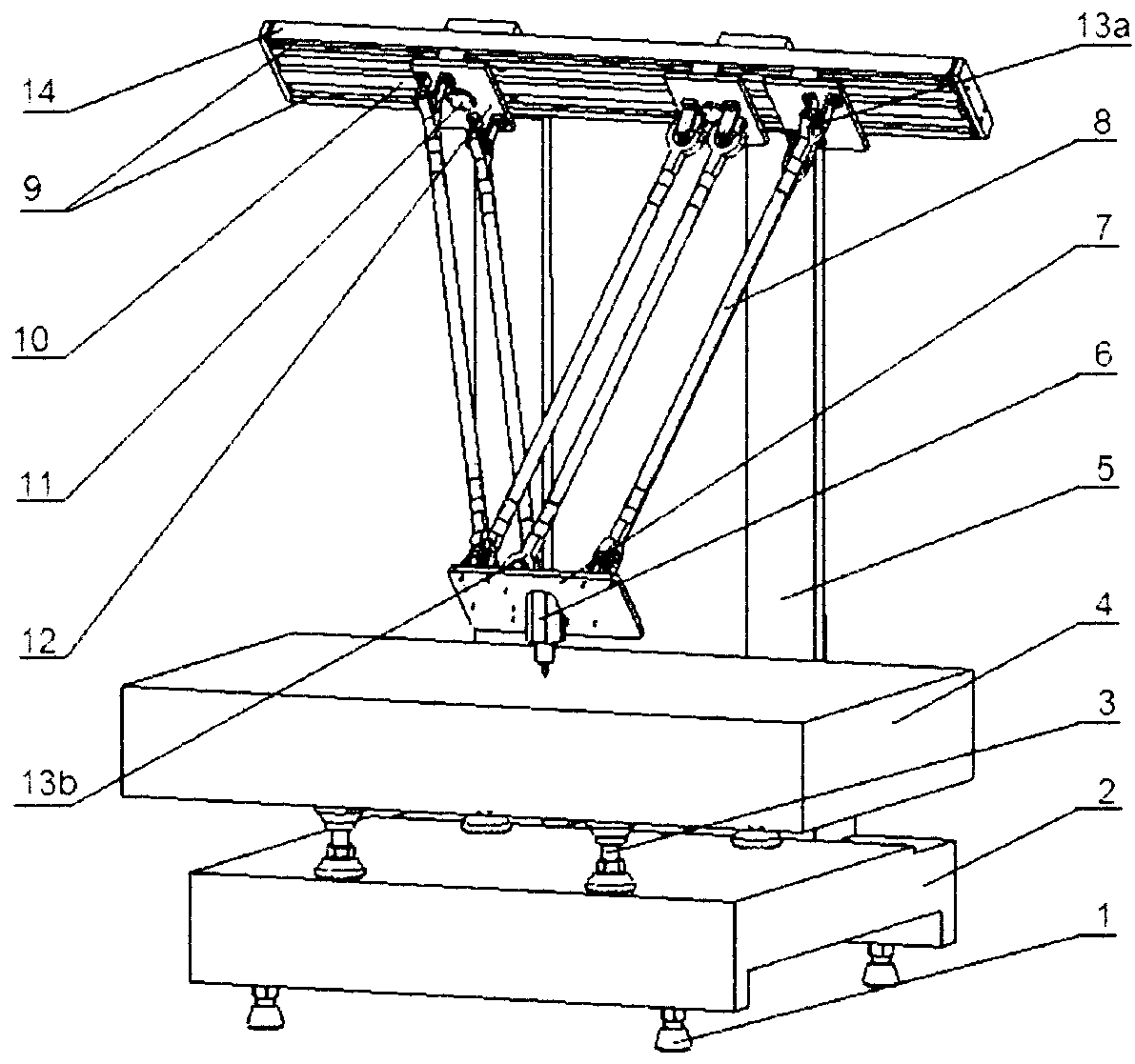

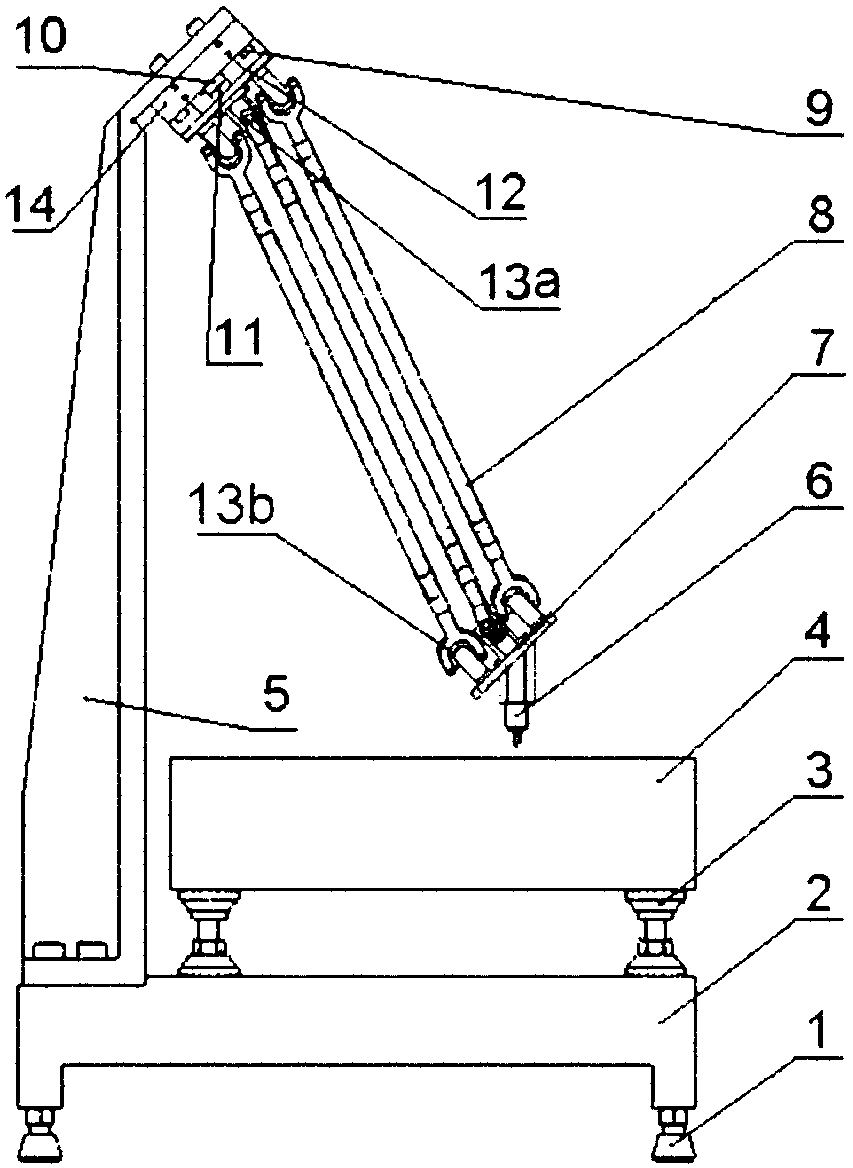

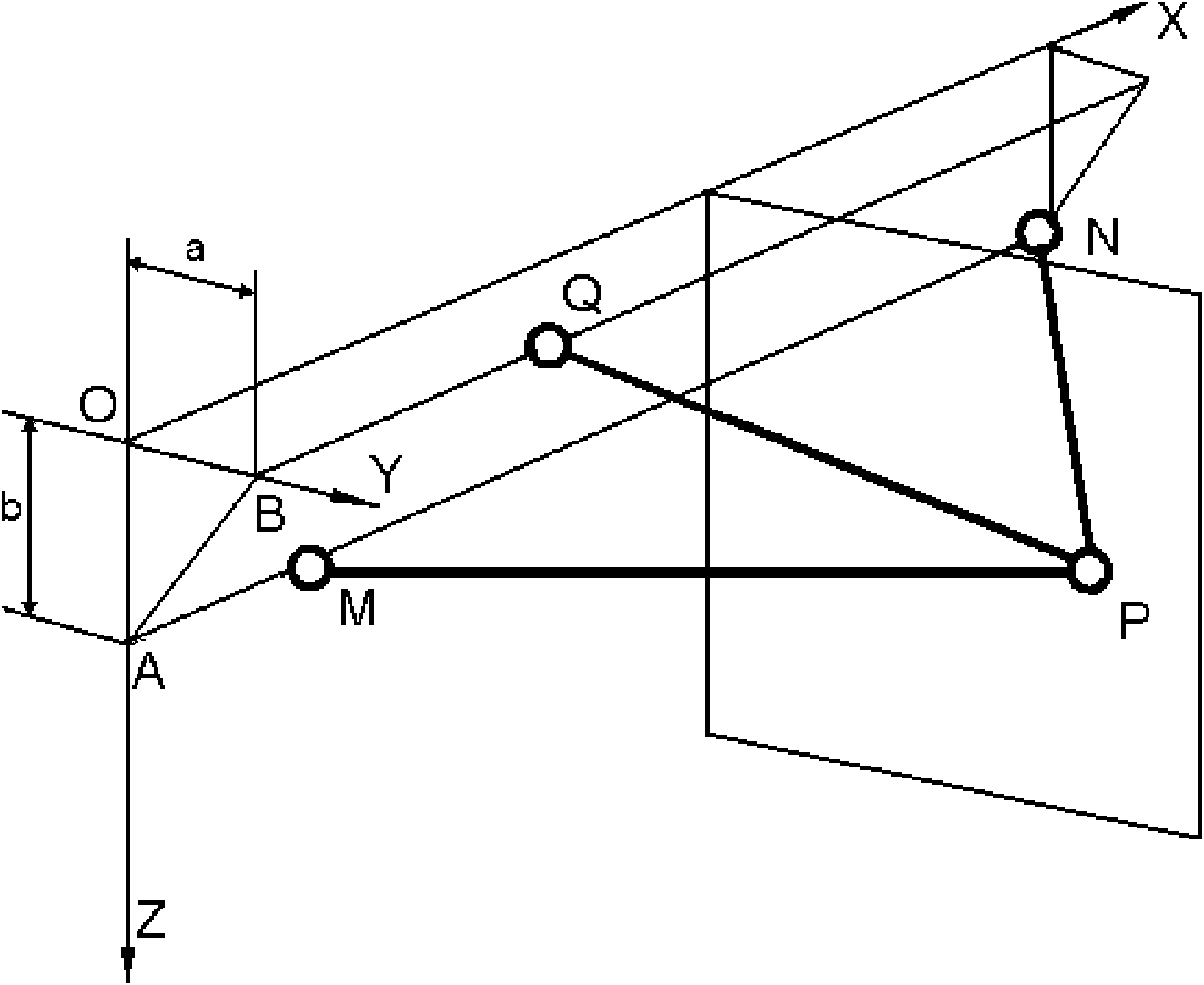

[0030] see figure 1 , figure 2 with image 3 , set up three pairs of moving pair-spherical hinge-spherical hinge parallel mechanism, the parallel mechanism is to independently set three motion sliders 12 on a pair of ball guide rails 9 arranged in parallel, and the three motion sliders 12 can respectively move along the ball guide rail 9 Free sliding; the three moving sliders 12 are respectively connected to one end of the three pairs of link rods 8 through one end universal joint 13a, and the other ends of the three pairs of link rods 8 are respectively connected to the measuring moving platform 7 through the other end universal joint 13b. Measuring head 6 is installed on the lower plane of moving platform 7;

[0031] The three indicator gratings 11 are fixedly connected to the three moving sliders 12 respectively, and a scale grating 10 is arranged parallel to a pair of ball guide rails 9 and installed on the rail beam 14 together; the rail beam 14 is suspended and fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com