High-cavity precision bottle cap die of novel HALF block structure

A block structure and a new type of technology, applied in the field of high-cavity precision bottle cap molds, can solve the problems of difficulty in ensuring the flatness, parallelism, and perpendicularity of large inclined planes, the inability to effectively protect the HALF block, and the inaccurate positioning of the HLAF block. Achieve the effect of reducing the possibility of mold falling, reducing weight and easy processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

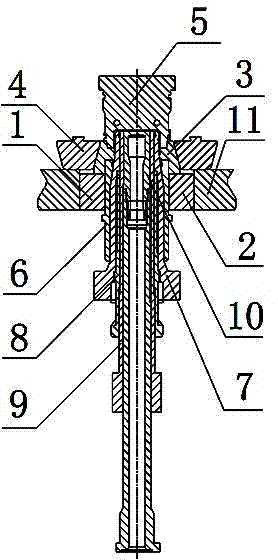

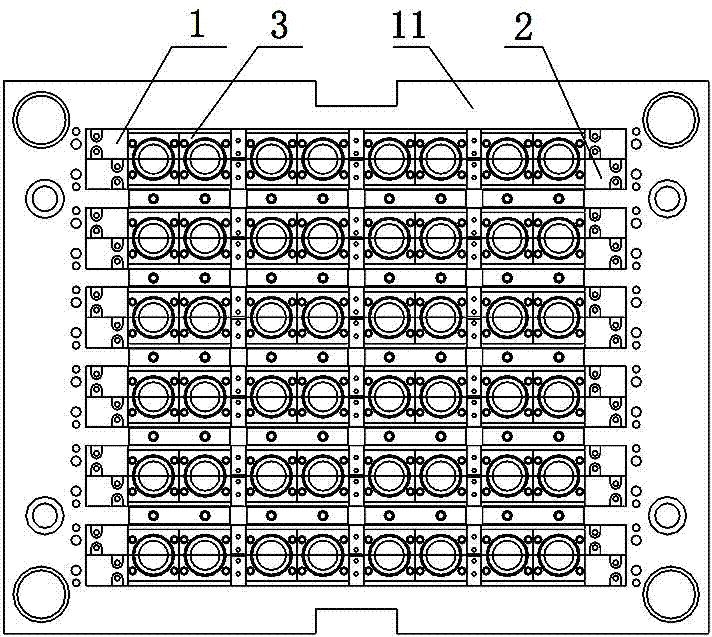

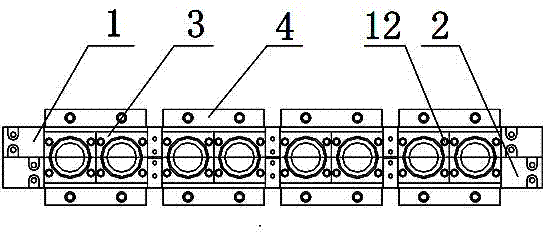

[0022] Such as figure 1 with Figure 4 As shown, the high-cavity precision bottle cap mold of the new HALF block structure includes HALF block 3, cavity 5, large slider A1, large slider B2, wedge block 4, push ring 6, thread core 7, cooling water Core 8, push tube 9 and inner core 10, the upper and lower ends of HALF block 3 are respectively provided with positioning taper holes 14 and positioning straight holes 15, both sides of HALF block 3 are provided with inclined surfaces 13, and cavity 5 is matched and installed in the positioning taper holes Inside 14, both sides of the HALF block 3 are provided with wedge tight blocks 4, the wedge tight blocks 4 are closely matched with the inclined surface 13, and the hollow push ring 6 is installed in the inside of the positioning...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com