Thick broad-bean sauce fermented by mixed pure strains and preparation method thereof

A technology of mixed fermentation and bean paste, applied in food science and other directions, to achieve the effect of improving safety, controlling potential safety hazards, and avoiding pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Soak the shelled dried broad bean in water for 2 hours to make the water fully swell until the section has no white hard core.

[0032] (2) Drain the soaked wet broad beans, put them in a steamer and steam until the surface layer is steamed, cover and keep for 30 minutes, then stop the fire and simmer for 10 minutes before taking out of the pot.

[0033] (3) Cool the watercress out of the pan to room temperature under sterile conditions, and inoculate the number of spores to 10 7 Aspergillus oryzae spore powder 5g of each / g, spore number is 10 7 Put 5g of Aspergillus sojae spore powder and 50g of flour per gram into 500g of watercress, and mix well.

[0034] (4) Cultivate the inoculated broad bean flaps in an incubator at 30°C for 48 hours to prepare koji;

[0035] (5) Ferment 250g of finished koji and 500mL of sterile saline with a concentration of 12w%, and ferment in a constant temperature box at 45°C for 30 days to obtain Doubanjiang.

Embodiment 2

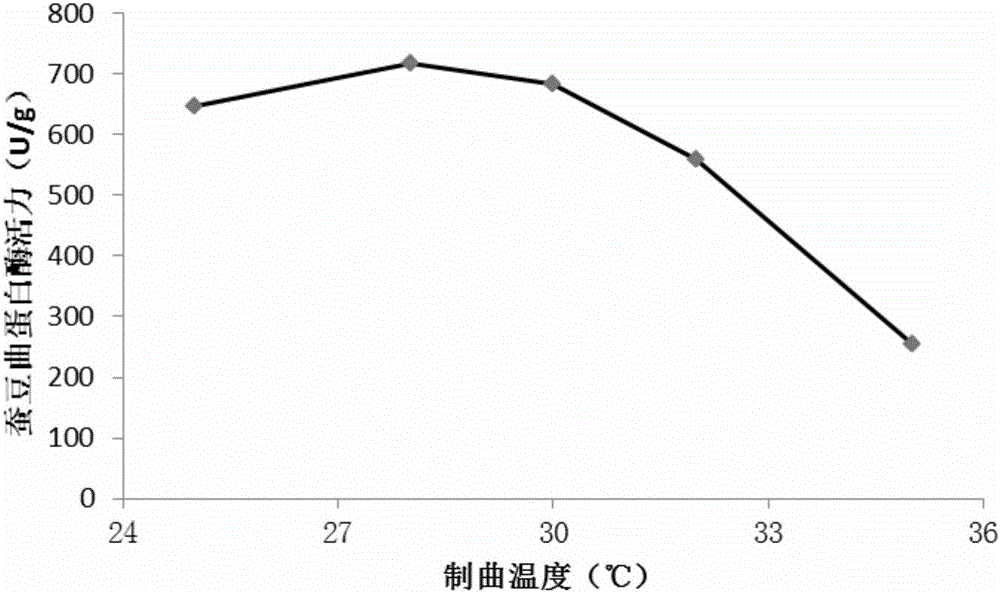

[0037] According to the method of Example 1, just change the culture temperature of the koji (change the culture temperature from 30°C to 25°C, 28°C, 32°C and 35°C), and measure its influence on the protease activity of the koji, the results are as follows figure 1 shown.

[0038] Depend on figure 1 It can be seen that the protease activity of broad bean koji has certain changes at different temperatures, and reaches the highest at 28°C. The koji material is fluffy, uniform in color, and basically free of ammonia and other bad odors. decreasing gradually. Therefore, it is more appropriate to control the temperature of koji making at 28°C.

Embodiment 3

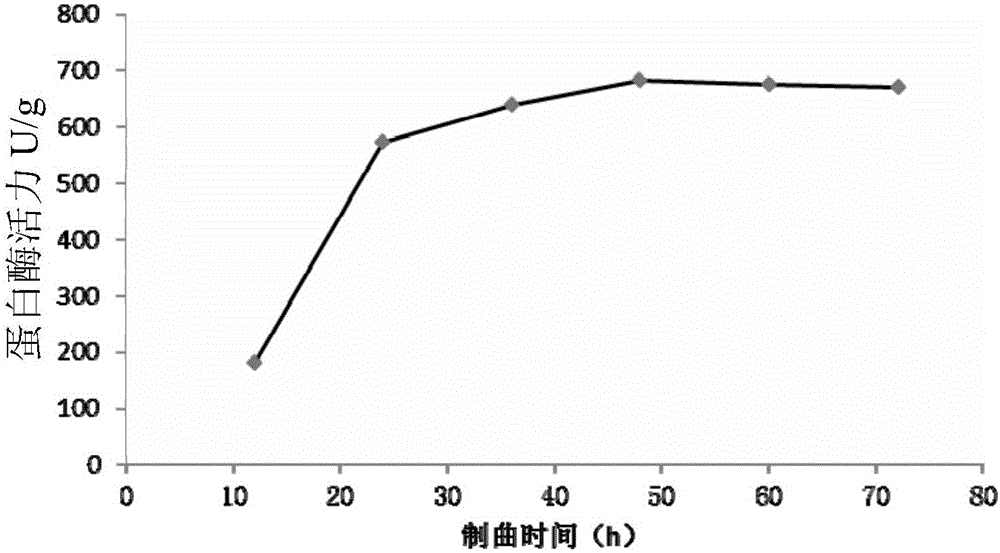

[0040] According to the method of Example 1, just change the culture temperature of the koji (change the culture temperature from 30°C to 28°C) and the culture time (change the culture time from 48h to 12h, 24h, 36h, 60h, 72h), and measure its pairing. The effect of trypsin activity, the results are as follows figure 2 shown.

[0041] Depend on figure 2 It can be seen that when the koji making time is 48 hours, the protease activity of broad bean koji reaches the maximum value, the koji material has no agglomeration, a large number of green-brown spores are produced on the surface, the color is uniform, the musty smell is strong, and there is basically no ammonia smell. Vitality decreased a little but basically remained stable. Therefore, the optimum time for making broad bean koji was 48 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com