Preparation method of spinel type lithium manganate or lithium nickel manganese oxide

A type of lithium manganese oxide and lithium nickel manganese oxide technology, which is applied in the field of lithium-ion battery cathode materials, can solve problems such as poor crystal structure consistency and achieve good structural consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

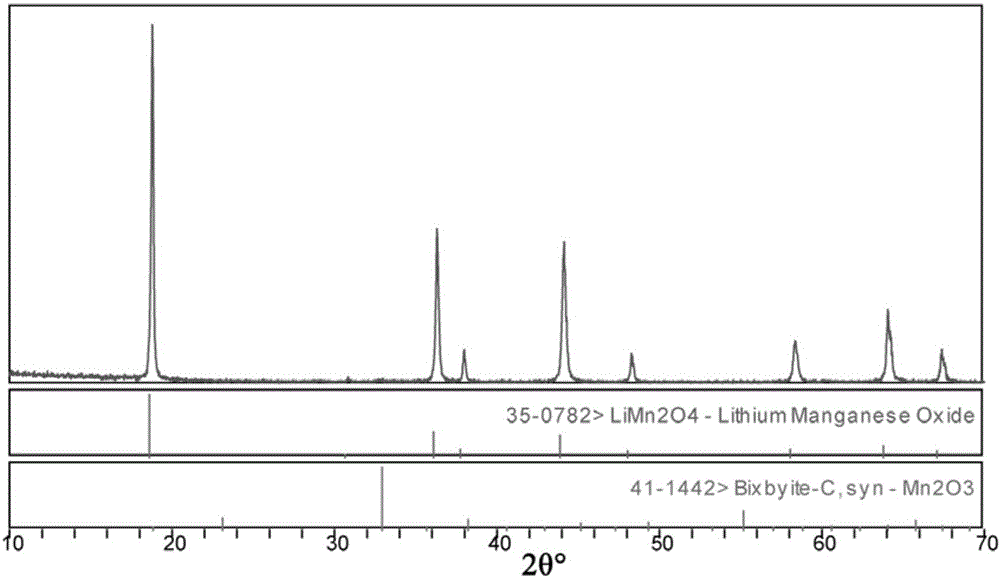

Embodiment 1

[0047] According to the ratio of Li:Mn=1:1.8, weigh 11.1g (0.15mol) lithium carbonate and 62g (0.54mol) manganese carbonate, dissolve in 70mL water, weigh 4.4g according to 6% of the total weight of lithium carbonate and manganese carbonate Cotton pulp (CP1000u type cotton pulp produced by Shandong Gaomi Chemical Fiber Group Co., Ltd.), was added to water, stirred evenly to obtain a colloidal suspension, and then the colloidal suspension was dried at 110°C for 14 hours to obtain a precursor, and then The precursor is placed in a sagger and calcined at 800°C for 4 hours to obtain spinel lithium manganate.

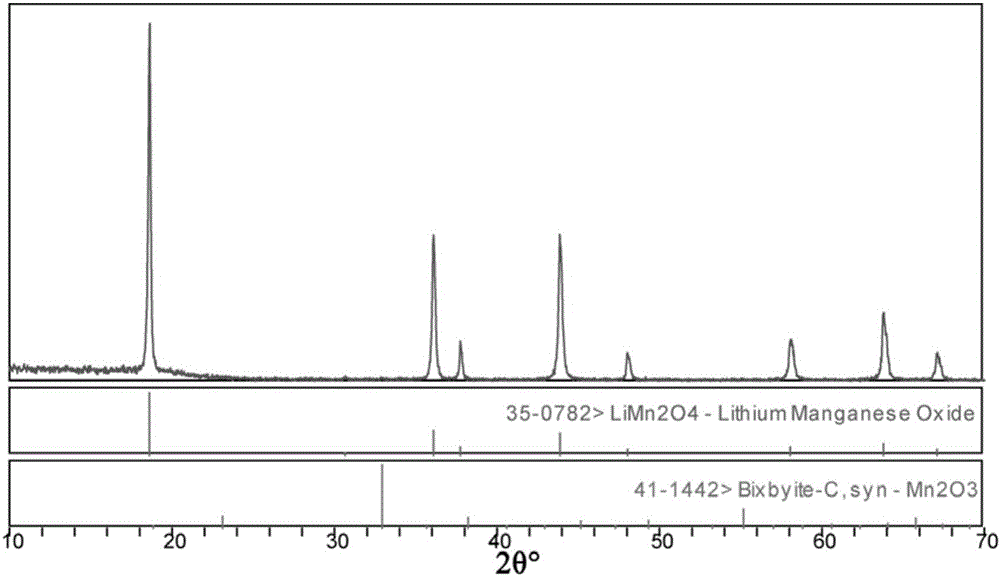

Embodiment 2

[0049] According to the ratio of Li:Mn=1:2, take by weighing 11.1g (0.15mol) lithium carbonate and 69g (0.6mol) manganese carbonate, take by weighing 2.4g cotton pulp according to 3% of lithium carbonate and manganese carbonate gross weight, will The three are ball milled in a ball mill for 10 hours, and then calcined at 800°C for 4 hours to obtain spinel lithium manganate.

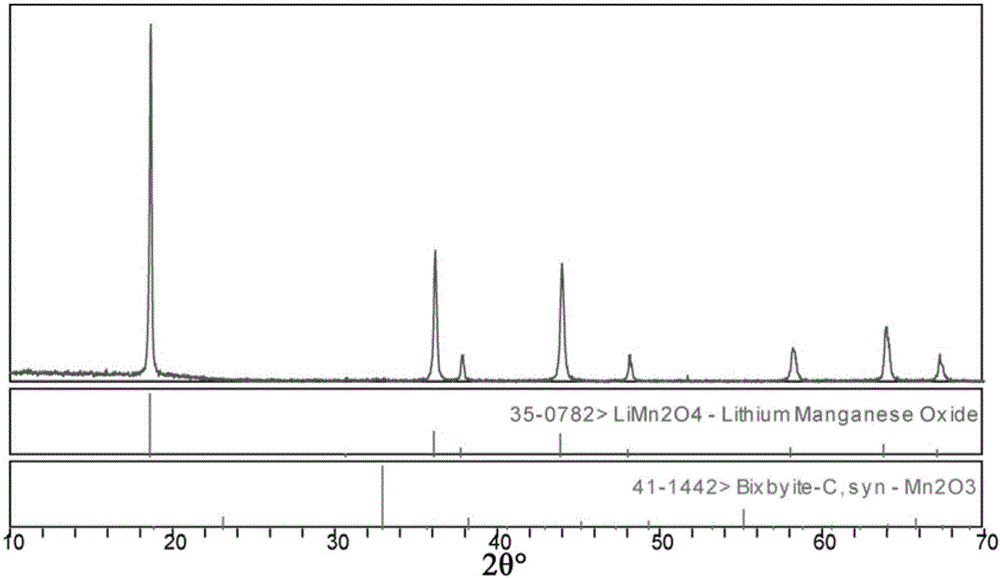

Embodiment 3

[0051] According to the ratio of Li:Ni:Mn=1:0.5:1.5, take by weighing 6.9g (0.1mol) lithium nitrate, 14.5g (0.05mol) nickel nitrate (hexahydrate nickel nitrate), 17.2g (0.15mol) manganese carbonate, Dissolve in 40mL water, weigh 0.39g wood pulp fiber according to lithium nitrate, nickel nitrate and manganese carbonate and 1% of the total weight (Lot145444-black needle pulp produced by Russia Ilim Company provided by Sinotrans Storage and Transportation Co., Ltd.), add Put it into water, stir evenly to obtain a colloidal suspension, then dry the colloidal suspension at 110°C for 14 hours, and then calcinate at 800°C for 4 hours to obtain spinel lithium nickel manganese oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com