Multi-stage heat storage device and copious cooling liquefied air energy storage system using multi-stage heat storage technology

A heat storage device and energy storage system technology, applied in refrigeration and liquefaction, liquefaction, refrigerators, etc., can solve the problems of low thermal energy storage rate and uneven thermal energy quality, and achieve high-quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

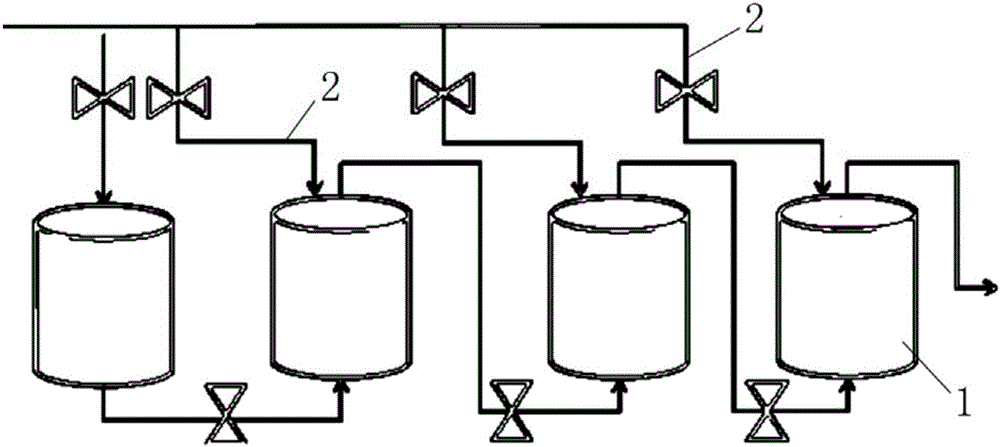

[0033] refer to figure 1 , this embodiment provides a multi-stage heat storage device, including a number of heat storage devices 1, the number of heat storage devices 1 is not less than 2, and any heat storage device 1 is connected to the thermal energy output end, so as to receive the heat energy output from the thermal energy output end. The thermal energy is stored in parallel, and the adjacent storage devices 1 are connected in series through the heat transfer channel 2, so that during the heat storage process, the heat energy escaped from the heat storage process of the previous stage heat storage 1 can enter through the heat transfer channel 2 to the heat storage device 1 of the subsequent stage, so as to preheat the heat storage device 1 of the subsequent stage. Moreover, the heat storage device 1 of the previous stage and the heat storage device 1 of the subsequent stage are used to store heat energy in different temperature ranges, so that when the heat energy is out...

Embodiment 2

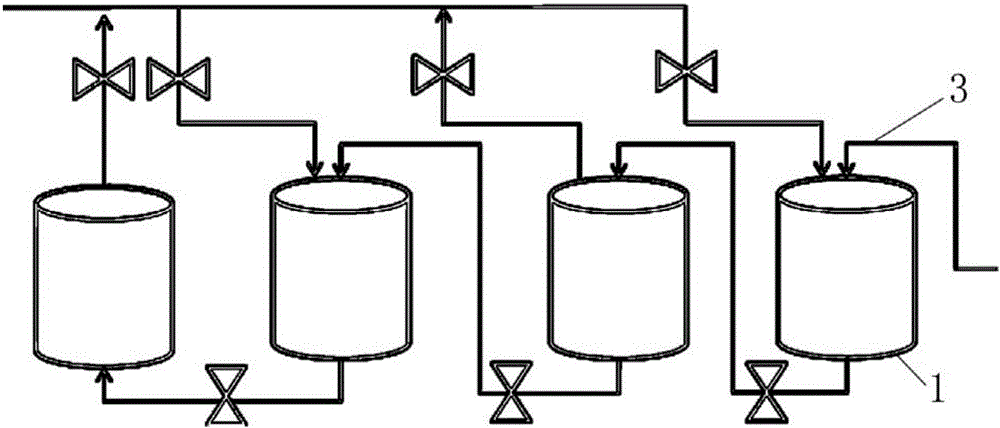

[0045] The difference between this embodiment and Embodiment 1 is that in this embodiment, only one of several heat storage devices 1 is used to connect to the output end of heat energy, and during the heat storage process, the heat energy is sequentially stored in the heat storage devices 1 at various levels. In, the energy release process is the same as in Example 1.

[0046] Compared with Example 1, this heat storage method still contains more heat energy in the escaped exhaust gas, but the exhaust gas discharged from the heat storage device 1 of the previous stage can still be pre-heated for the heat storage device 1 of the subsequent stage. Therefore, compared with the heat storage device in the prior art, the heat storage rate can still be improved to a certain extent, and the waste of heat energy can be reduced.

Embodiment 3

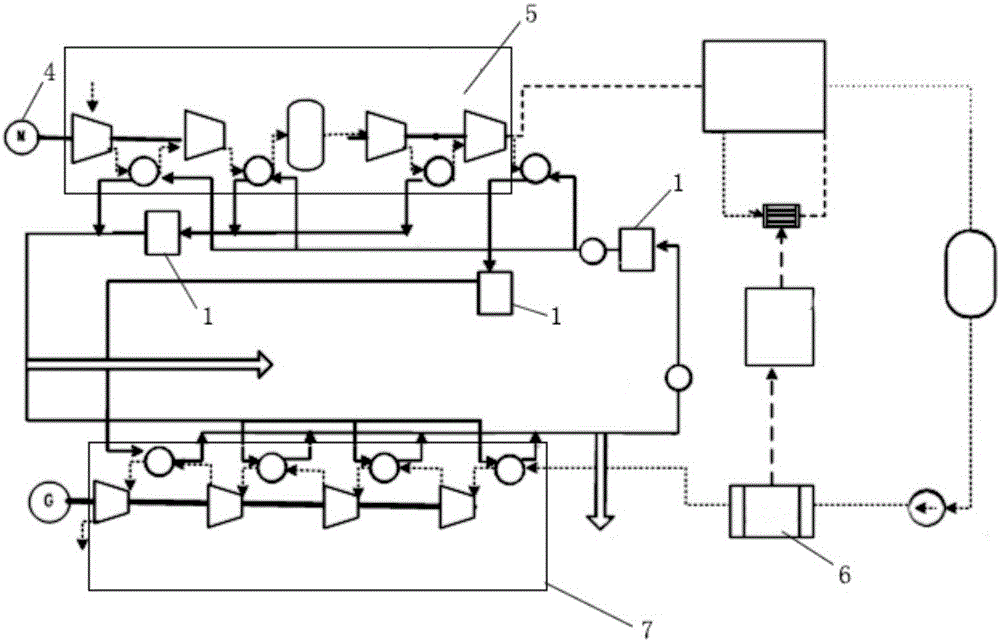

[0048] The following combination image 3 Describe in detail the multi-stage heat storage device of the cryogenic liquefied air energy storage system using the multi-stage heat storage technology provided in this embodiment. The multi-stage heat storage device of the cryogenic liquefied air energy storage system using the multi-stage heat storage technology includes: an energy input device 4, Used to input energy into the energy storage system;

[0049] The air compression device 5 is driven by the energy input device 4 to compress gaseous air into liquid air;

[0050] Gasification device 6, gasifying the liquid air;

[0051] And, the multi-stage heat storage device described in Embodiment 1 or 2 stores heat energy generated during the liquefaction of gaseous air in the air compression device 5 .

[0052] The above-mentioned embodiment is the core technical solution of this embodiment. The multi-stage heat storage device described in Embodiment 1 or 2 is used in combination ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com