Ceramic sealing type rotational steam valve

A ceramic sealing and rotary technology, used in the field of steam valves, can solve the problems of cavitation erosion of seals, valve inner leakage and outer leakage valve service life, corrosion and other problems, and achieve good sealing performance, fast switching speed and long service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following embodiments will further illustrate the present invention in conjunction with the accompanying drawings.

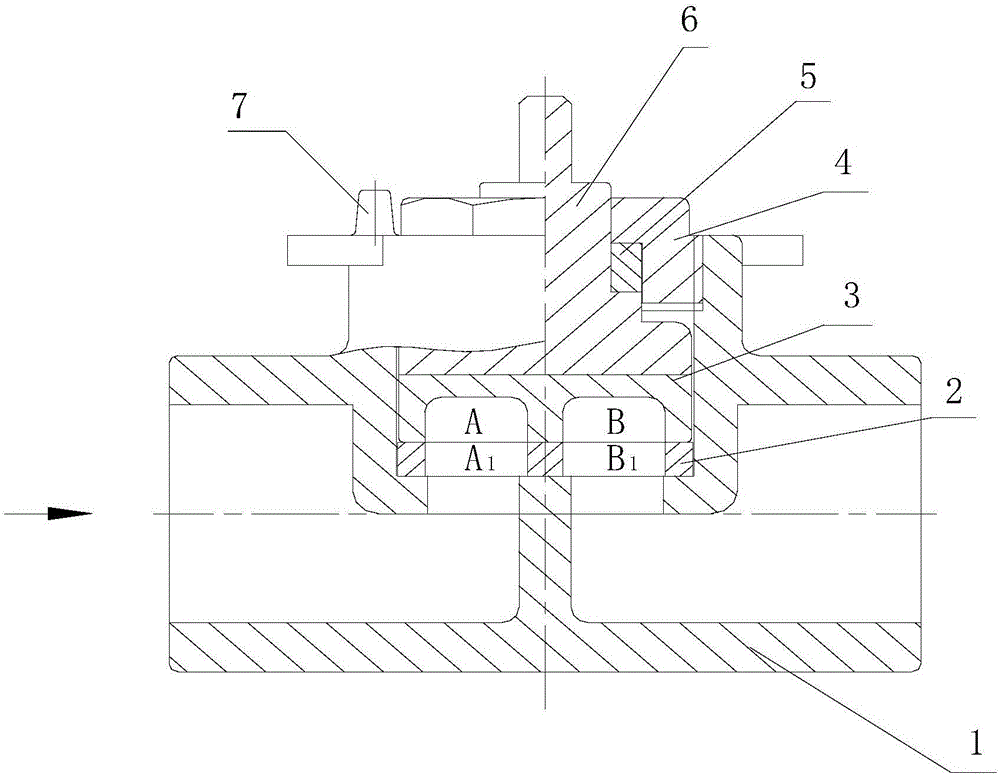

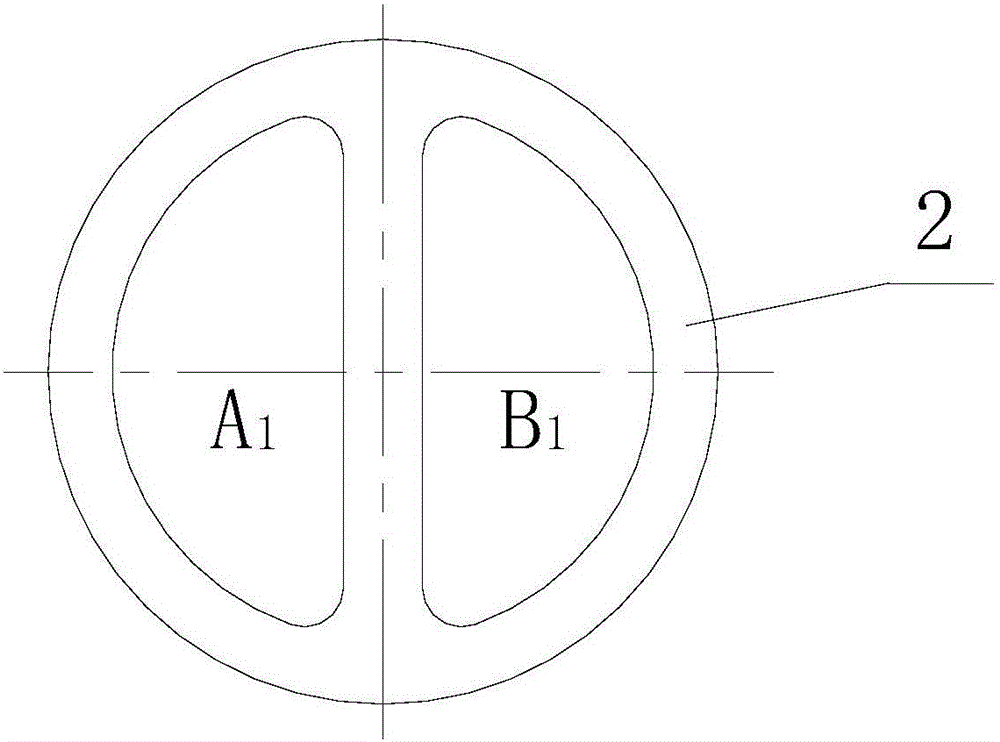

[0017] see figure 1 and 2 , the embodiment of the present invention is provided with a valve body 1, a lower seal ring 2, an upper seal cover 3, a compression nut 4, an adjustment washer 5, an operating rod 6, and a limit post 7; the lower seal ring 2 is loaded into the valve body 1 At the bottom of the inner cavity, the lower sealing ring 2 is connected with the valve body 1 as a whole; the upper sealing cover 3 is arranged on the upper part of the lower sealing ring 2; the lower end of the operating rod 6 is provided with a cross boss, and the top of the upper sealing cover 3 is provided with a cross groove. The cross convex platform is inserted into the cross concave platform, and the operating rod 6 drives the upper sealing cover 3 to rotate; the inner hole of the compression nut 4 is provided with a concave platform, and the outer circle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com