Method for removing arsenic from arsenic-contained smoke

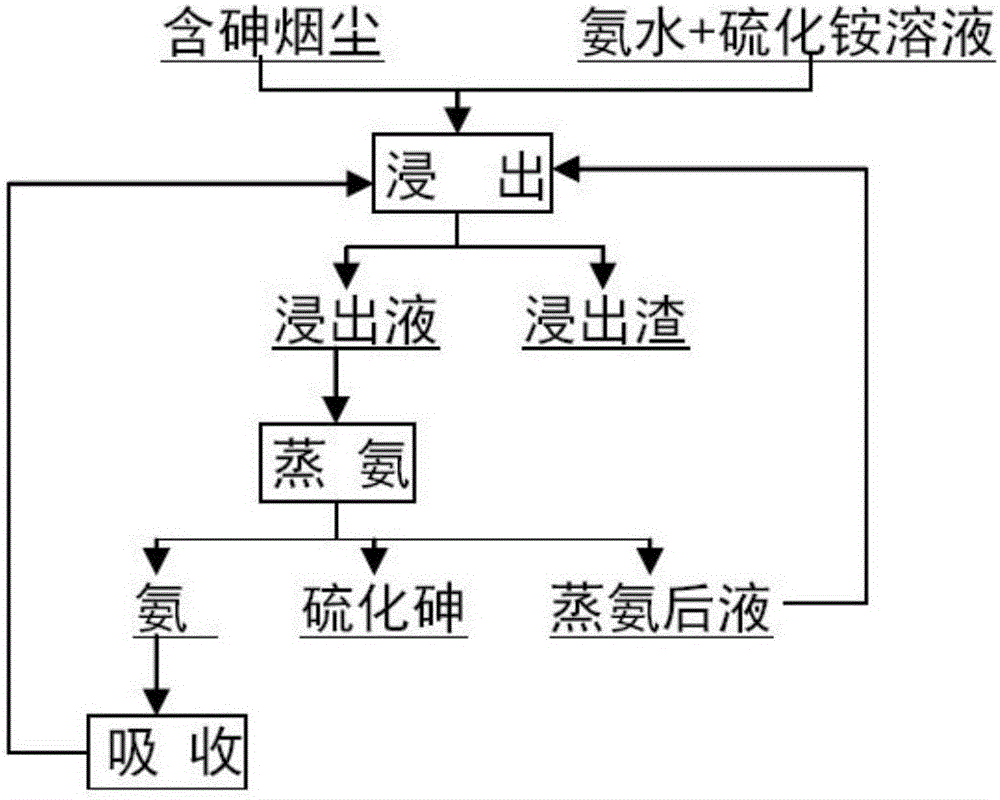

A technology for arsenic fume and dust removal, which is applied in the field of arsenic removal, can solve problems such as the failure of alkaline leaching to achieve selective arsenic leaching, high consumption of acid leaching reagents, long process flow, etc., to meet the requirements of clean production, low toxicity, and process short process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] (1) Leach 40g of arsenic-containing dust (containing As 14.4%, Pb 17.7%, Cu 10.3%) with ammonia water and ammonium sulfide solution, the leaching liquid-solid ratio is 5:1, the concentration of ammonium sulfide is 100g / L, and the concentration of ammonia is 20g / L, the leaching time is 2h, the leaching rate of arsenic is 92.6%, and the leaching rate of lead and copper is less than 5%.

[0019] (2) The arsenic-containing leaching solution obtained in step (1) is evaporated at 90° C. to deammoniate, and the arsenic is precipitated in the form of arsenic sulfide to obtain arsenic sulfide precipitate containing 52.2% of arsenic.

[0020] (3) Absorb the ammonia produced by evaporation in step (2) and use it in step (1).

[0021] (4) Return the ammonia-distilled liquid in step (2) to step (1) to leach arsenic fumes.

Embodiment 2

[0023] (1) Leach 40g of arsenic-containing dust (containing As 11.2%, Pb 15.6%, Cu 8.5%) with ammonia water and ammonium sulfide solution, the leaching liquid-solid ratio is 4:1, the concentration of ammonium sulfide is 120g / L, and the concentration of ammonia is 20g / L, the leaching time is 2h, the leaching rate of arsenic is 91.2%, and the leaching rate of lead and copper is less than 5%.

[0024] (2) The arsenic-containing leaching solution obtained in step (1) is evaporated at 95° C. to deammoniate, and the arsenic is precipitated in the form of arsenic sulfide to obtain arsenic sulfide precipitate containing 51.6% of arsenic.

[0025] (3) Absorb the ammonia produced by evaporation in step (2) and use it in step (1).

[0026] (4) Return the ammonia-distilled liquid in step (2) to step (1) to leach arsenic fumes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com