Production method for glass micro-beads and apparatus for same

A production method and technology of glass microbeads, which are applied in glass production, glass forming, glass manufacturing equipment, etc., can solve the problems of large heat energy consumption, slow cooling and solidification speed of microbeads, mutual adhesion into agglomerates and sticking to walls, etc. Achieve the effect of saving energy, reducing the phenomenon of mutual bonding and sticking to the wall, and improving the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to better clearly express the technical solution of the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

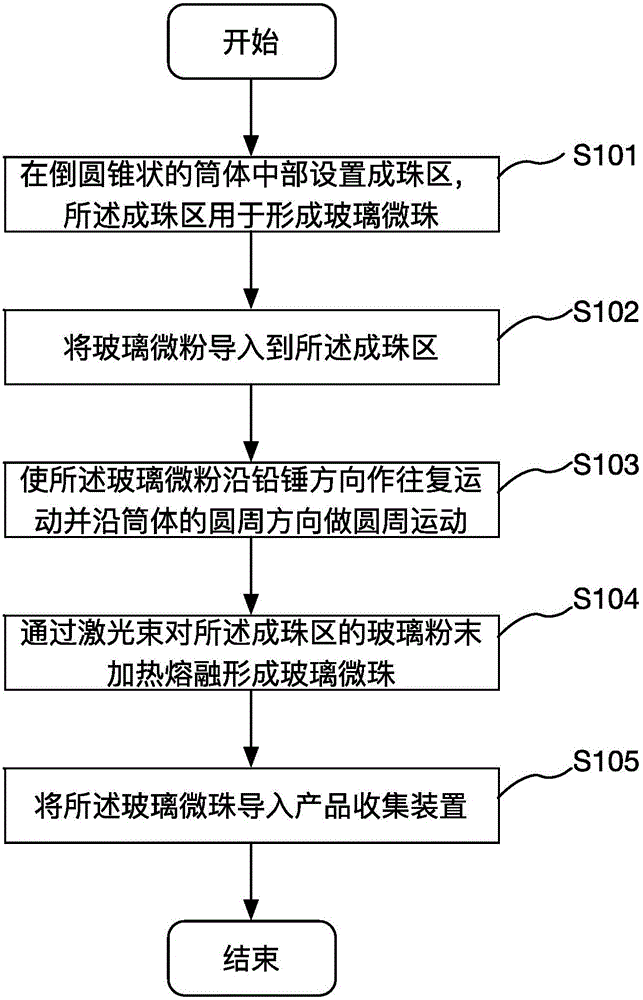

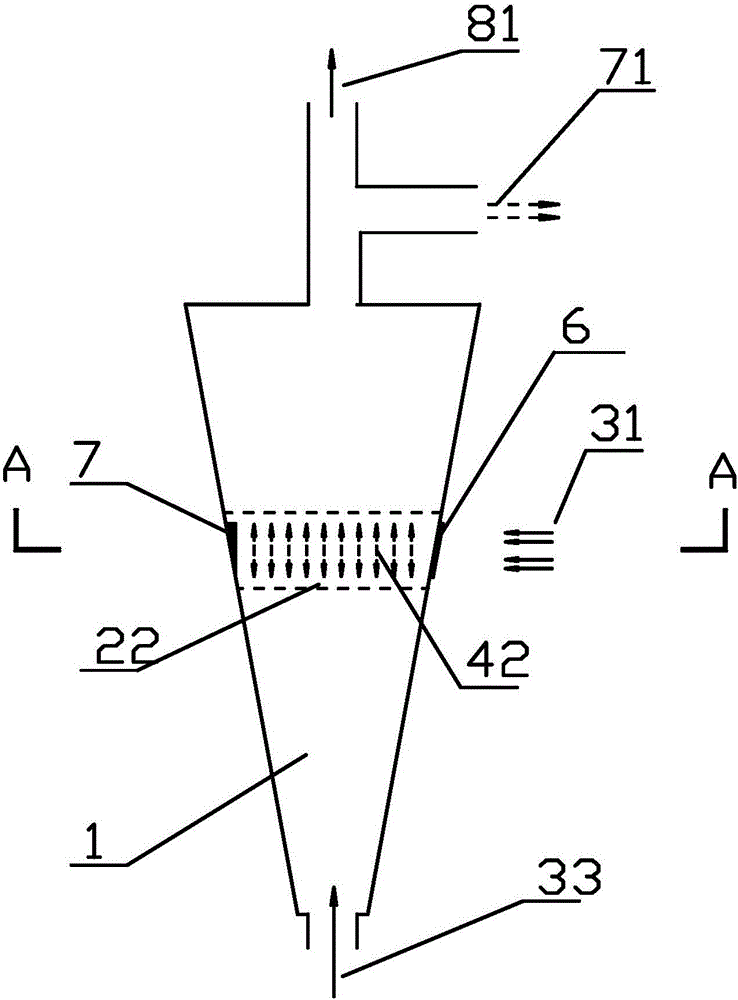

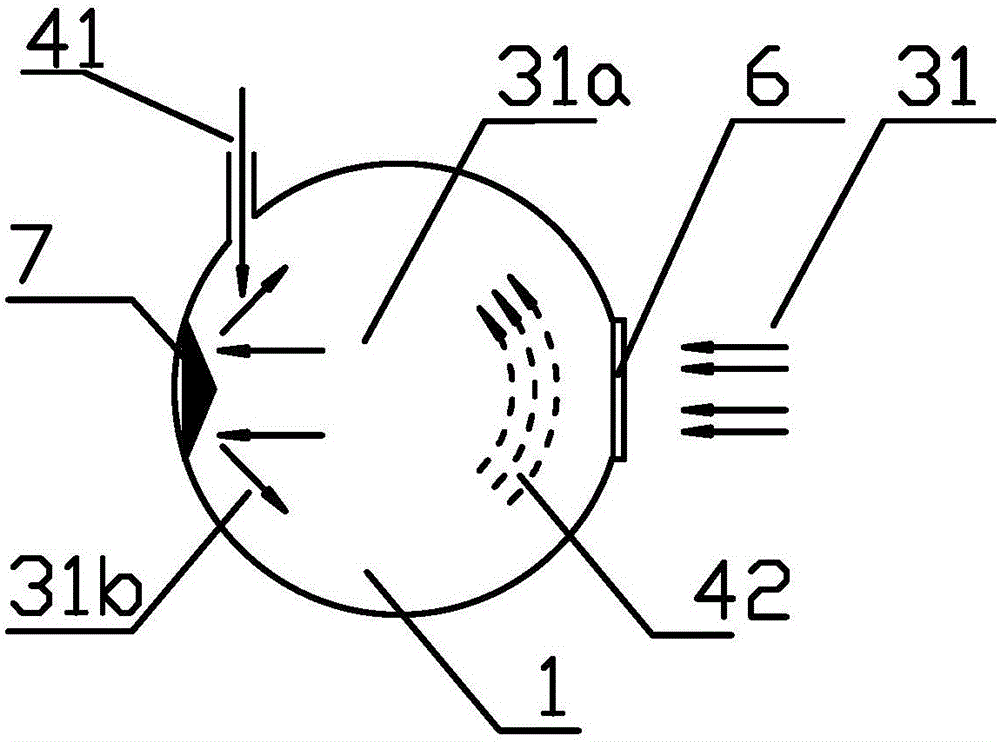

[0028] figure 1 Show a specific embodiment of the present invention, a flow chart of the production method of glass microspheres, figure 2 , image 3 Schematic diagrams of the application scenarios of the production methods are shown respectively. combine figure 1 , figure 2 as well as image 3 As shown, those skilled in the art can understand and realize the technical solution of the present invention more clearly. In such an embodiment, step S101 is performed first, and a beading area 22 is provided in the middle of the inverted conical cylinder 1, and the beading area 22 is used to form glass beads. Specifically, refer to figure 2 In the illustrated embodiment, preferably, the distance from the bottom boundary and the upper boundary of the beading zone along the vertical di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com