Chemical heat washing process equipment and treatment technology for thick oil and oil sludge oil field wastes

A technology of oilfield waste and treatment process, which is applied in the field of oilfield waste heavy oil sludge chemical thermal washing process equipment and treatment process, which can solve the problems of extended waste transportation distance, drilling production cost pressure, and extended treatment time period. Achieve the effects of moderate automation control, low equipment operation noise, and convenient operation and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

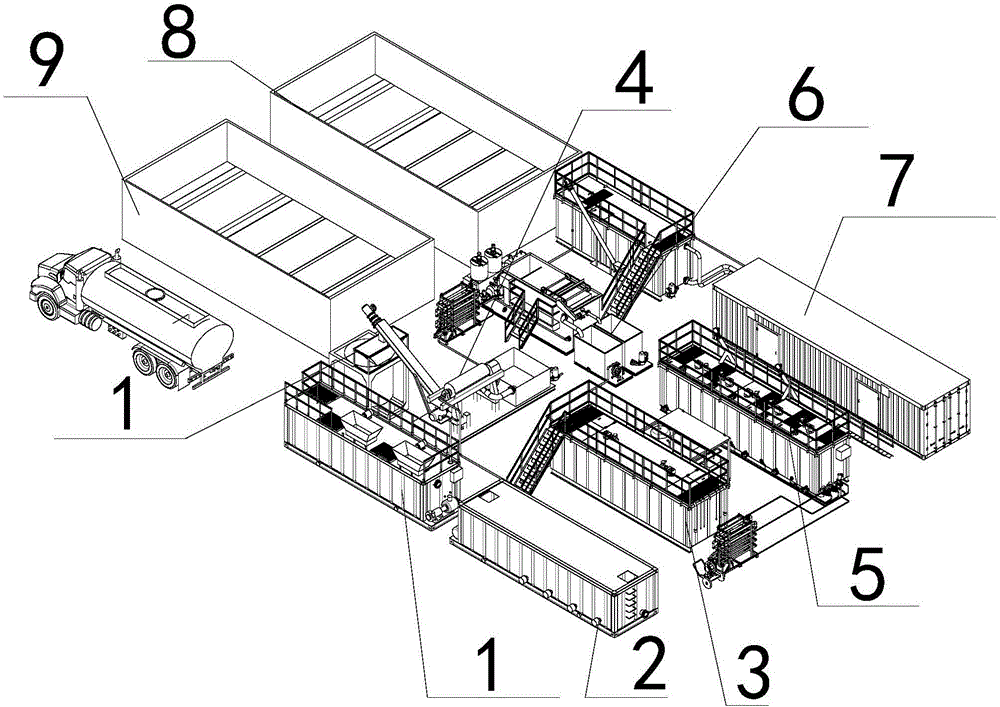

Image

Examples

Embodiment

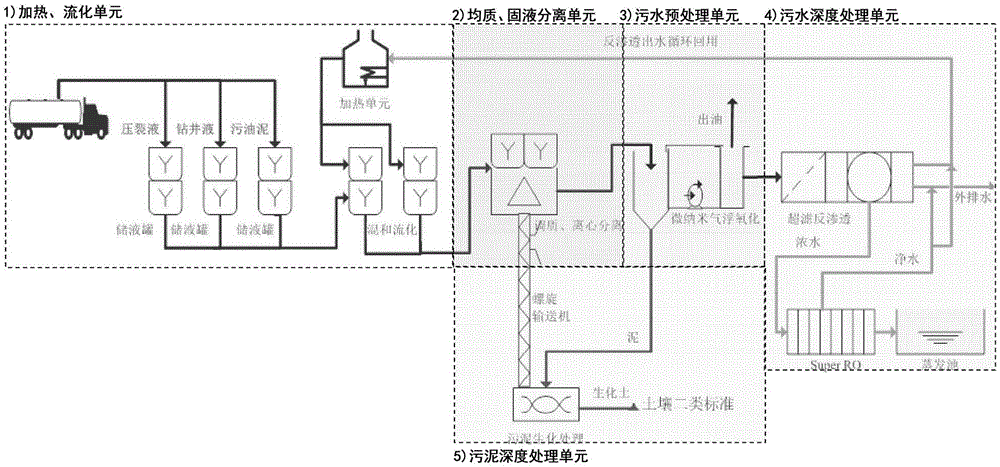

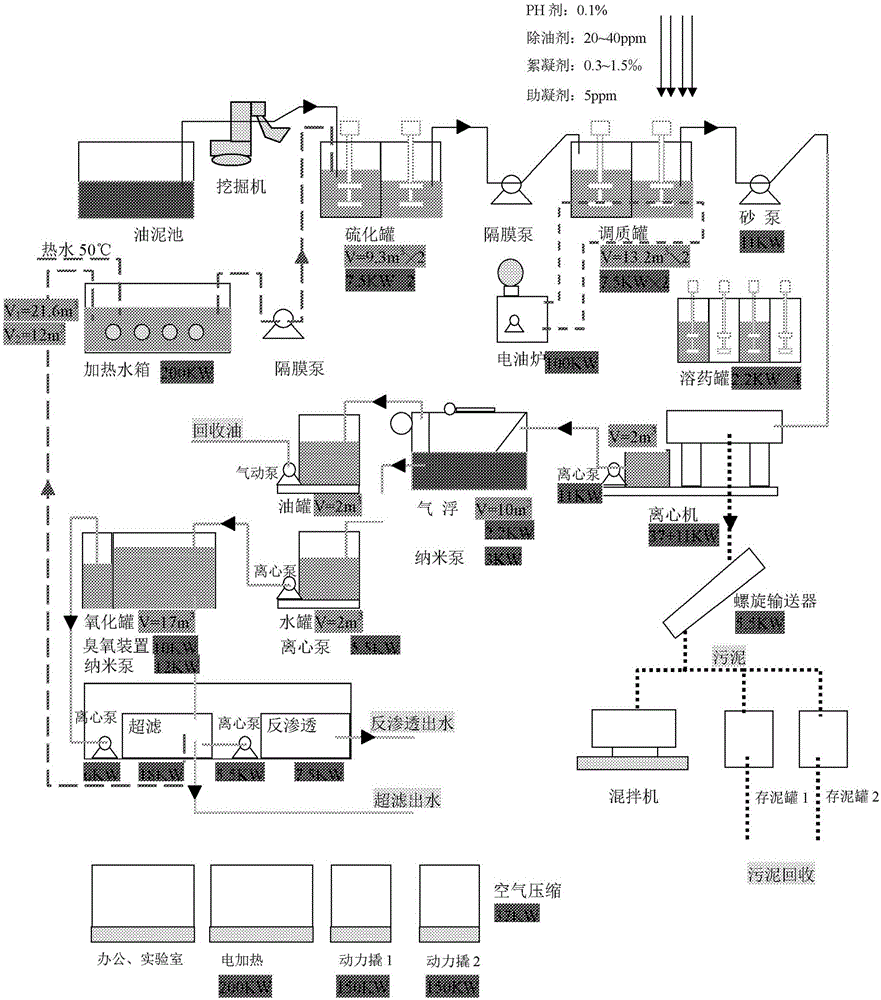

[0063] Heating and sludge fluidization unit

[0064] Select a special storage tank according to the incoming materials, and select a heating unit module and a fluidization unit module for early sludge fluidization and degreasing treatment.

[0065] Oilfield waste (fracturing fluid, drilling fluid and oil sludge) is sorted and stored after incoming materials;

[0066] The heating unit of the power distribution heat conduction oil furnace is used to heat the thick oil sludge that needs high-temperature fluidized oil washing;

[0067] According to the predetermined fluidization ratio and fluidization temperature, put oil sludge and hot water into the fluidization tank for fluidization operation.

[0068] The output from the fluidized tank enters the next process unit for conditioning and separation treatment.

[0069] Fluidization of thick oil sludge and separation of oil, mud and water by hot oil washing process;

[0070] High-efficiency micro-protein surfactant degreaser is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com