Spray nozzle for spraying amorphous alloy ribbon

A technology of amorphous alloys and nozzles, which is applied in the field of amorphous alloy spray belt production, and can solve problems such as easy clogging, burrs on the surface of the strip, and poor toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

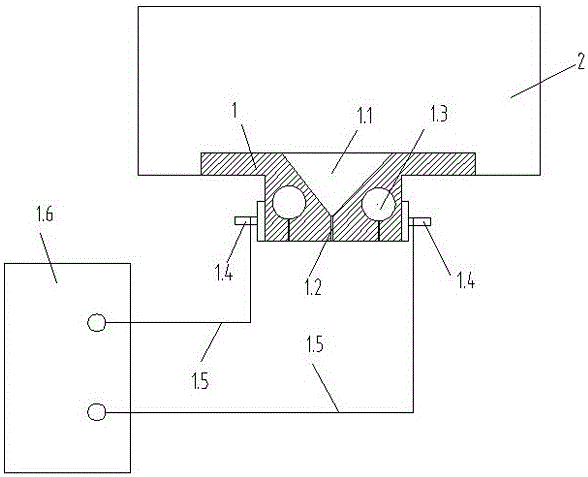

[0010] Embodiment 1: A nozzle for spraying amorphous alloy thin strips, the nozzle 1 is installed at the lower end of the spray bag 2, the nozzle 1 includes a substrate, the substrate inner cavity 1.1 is set in a V shape, and the center of the V shaped inner cavity 1.1 is opened There are spray slots 1.2 with a width of less than 0.3 mm, an air channel 1.3 is symmetrically opened on both sides of the V-shaped inner cavity 1.1 on the base body, and terminal posts 1.4 are provided on both sides of the base body, and the terminal posts 1.4 are connected to the positive and negative poles of the transformer 1.6 through lead wires 1.5 . The nozzle 1 is an anti-oxidation and heat-resistant metal material resistant to a high temperature of 1500 degrees.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com