Method for eliminating cylinder bottom sunken portion of warm-cold-formed inner cavity of thin-walled cylindrical piece

A thin-walled tube and tube bottom technology, which is applied in the field of cold-temperature extrusion of metal materials, can solve the problems of increasing production man-hours and wasting materials, and achieve the effects of improving production efficiency, reducing material consumption, and increasing production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further specifically described below through embodiments and in conjunction with the accompanying drawings.

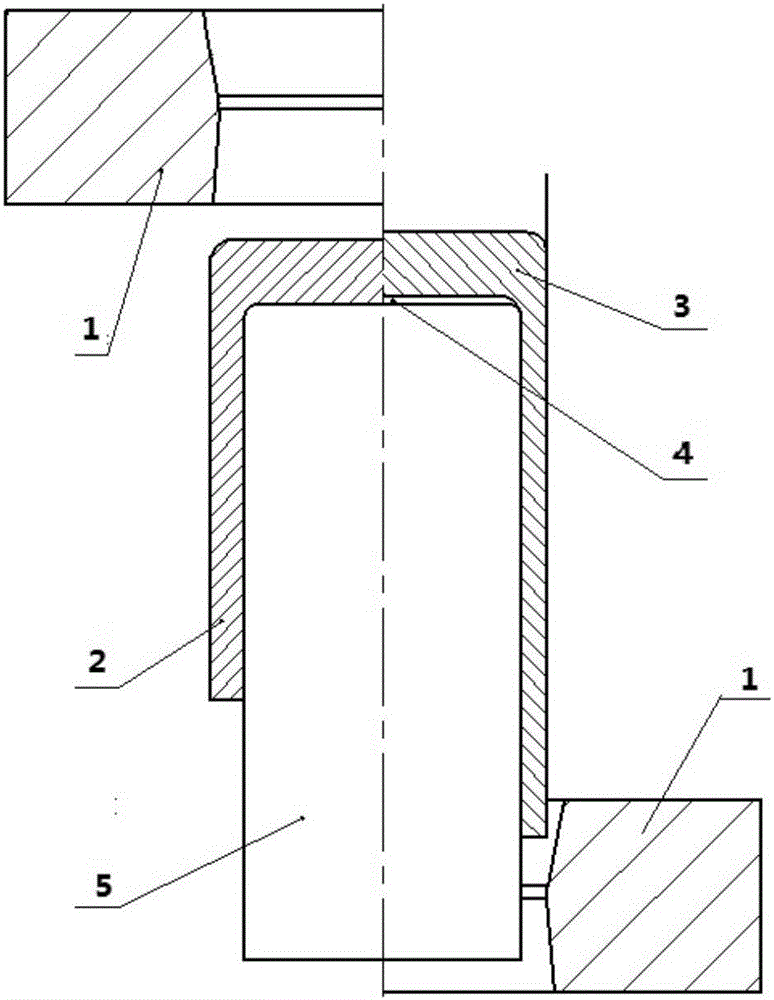

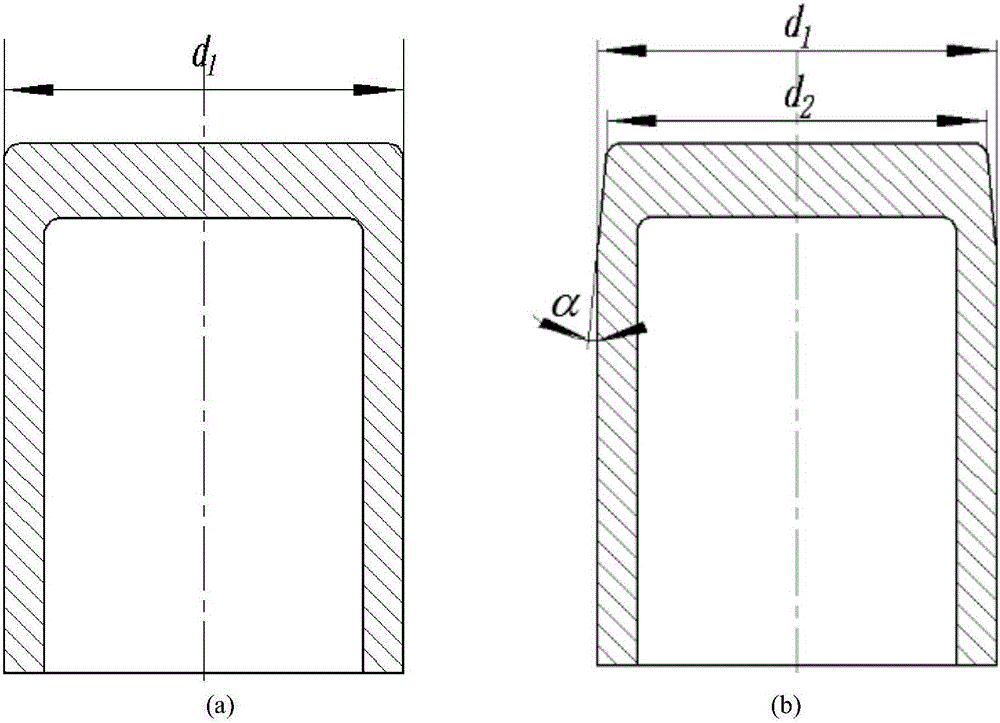

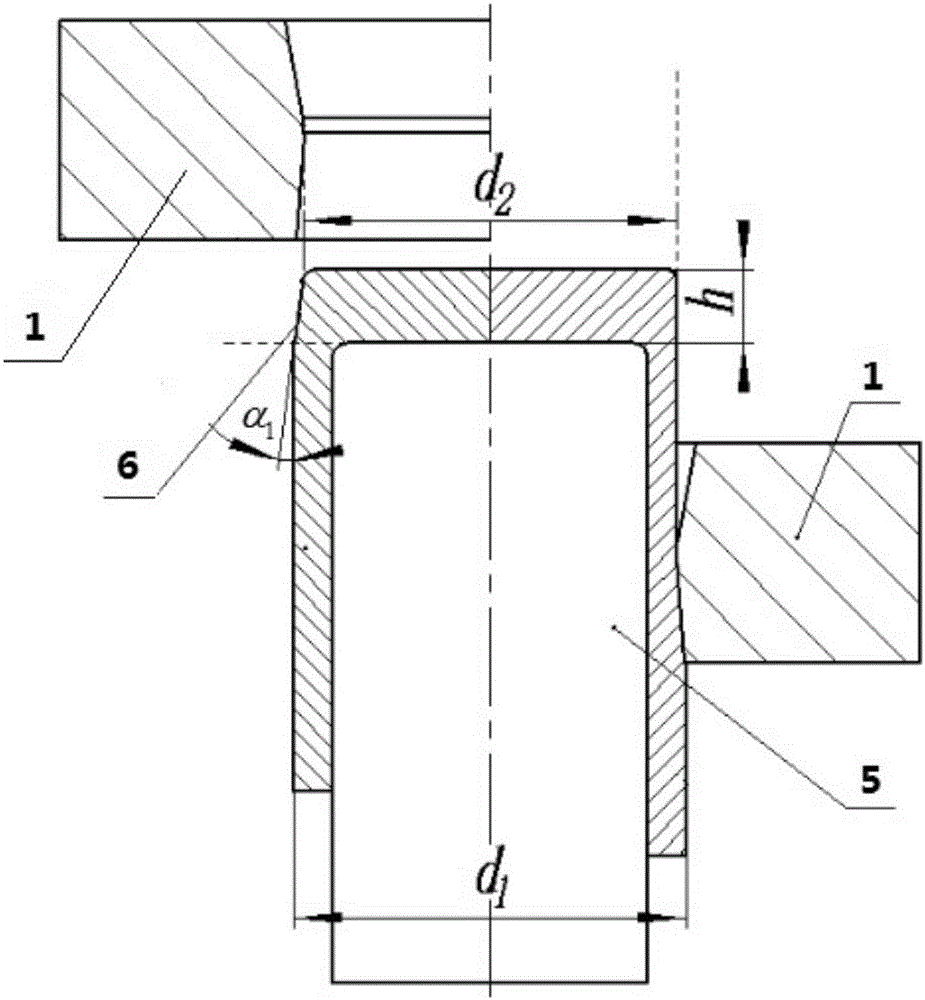

[0019] see image 3 As shown, the present invention provides a design method for the bevel angle of the bottom shoulder of the cylinder and directly forms the bevel angle α of the shoulder of the cylinder bottom in the warm extrusion process step, adopts a reverse extrusion die with a reasonable value of the bevel angle, and obtains a The cylindrical parts with bevel angle α at the shoulder of the bottom of the cylinder are subjected to annealing and phosphorus saponification before cold forming, and are directly subjected to the cold finishing process. The bottom of the cavity has concave defects, and a thin-walled cylindrical part that meets the shape, dimension accuracy and surface quality of the bottom of the cavity is obtained.

[0020] see Figure 4 with Figure 5 As shown, the embodiment of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com