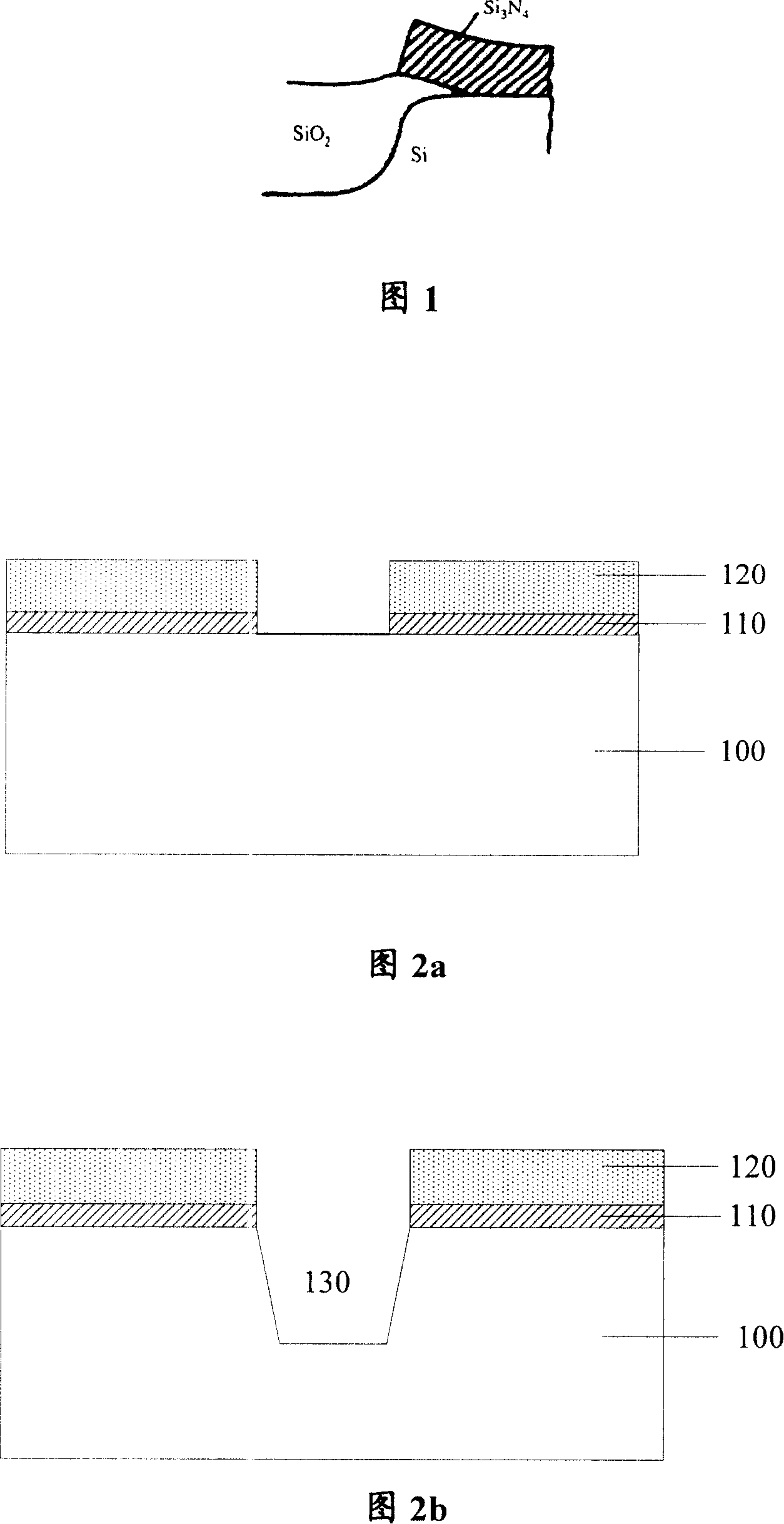

Method for forming isolation structure of shallow plough groove

A trench isolation and trench technology, which is applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of complicated process and unavoidable sidewall over-etching of the trench 70

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

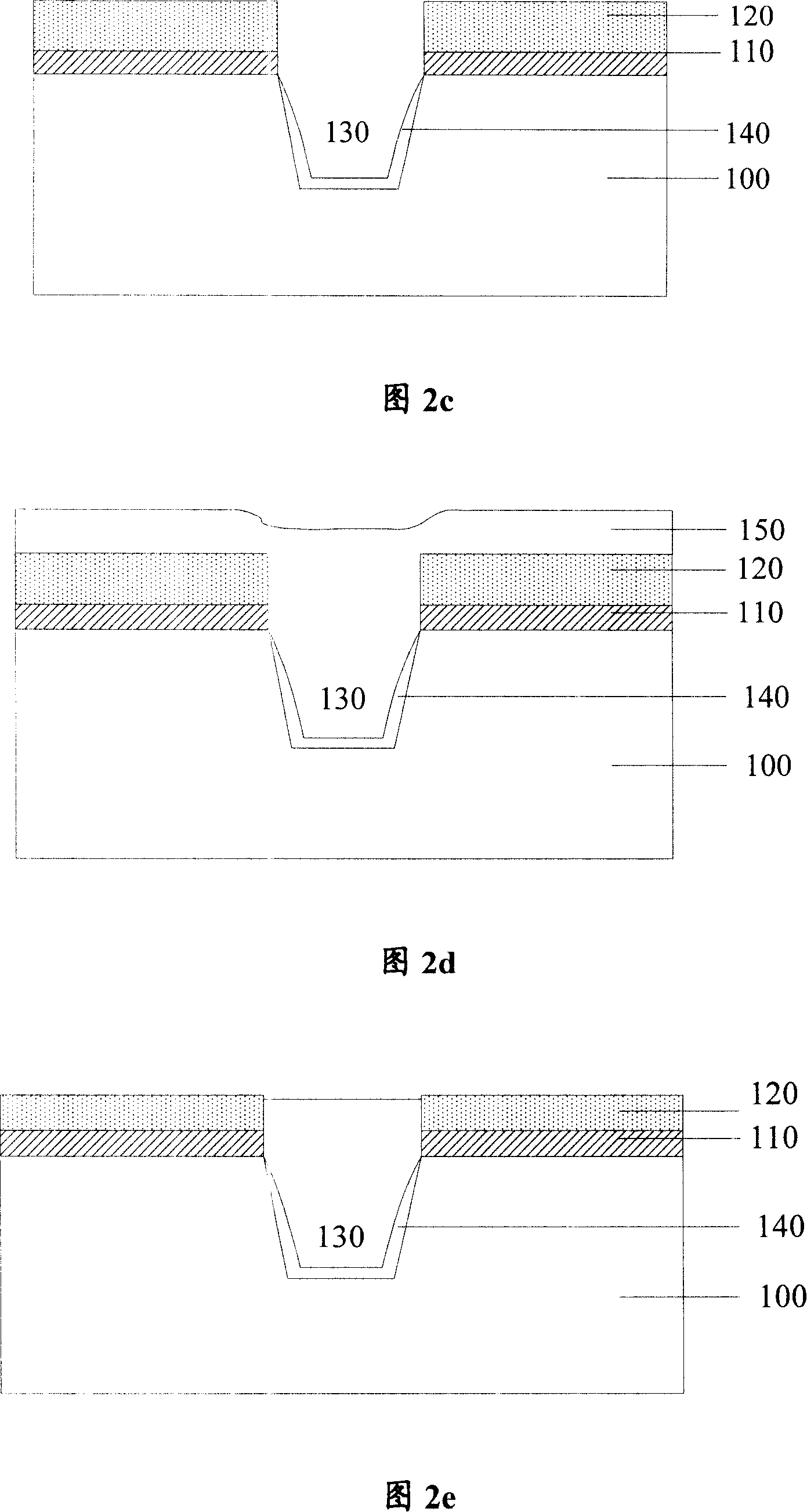

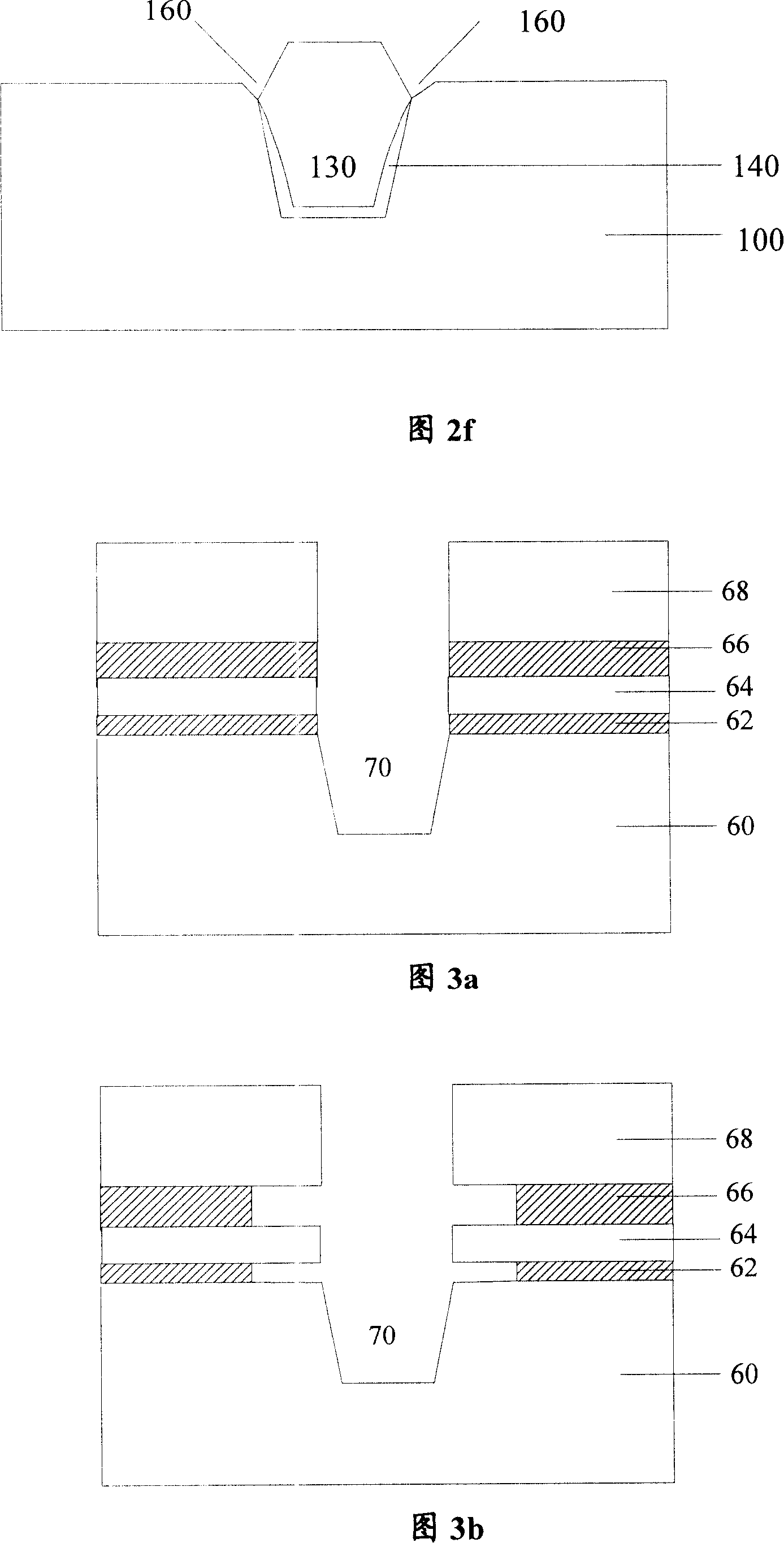

[0037] The present invention provides a method for forming a trench isolation structure. In a specific embodiment of the present invention, the method includes the following steps:

[0038] sequentially forming a pad oxide layer and a corrosion barrier layer on the semiconductor substrate, and sequentially defining the corrosion barrier layer, the pad oxide layer, and the semiconductor substrate to form trenches;

[0039] forming a liner oxide layer on the inner surface of the trench;

[0040] forming an isolation oxide layer filling the trench and covering the sidewalls of the pad oxide layer and the etch barrier layer;

[0041] planarizing the isolation oxide layer to expose the corrosion barrier layer;

[0042] Remove the corrosion barrier layer and the pad oxide layer on the semiconductor substrate in turn; after the corrosion barrier layer and the pad oxide layer are removed, a depression will be produced on the side wall of the trench, and in order to fill the depressio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com