Treatment device for surface of gap of turning wall

A technology for surface treatment devices and gaps, which is applied in the direction of grinding machines, metal processing equipment, grinding/polishing equipment, etc. It can solve the problems of inconvenient grinding and filling, easy hand slipping, and inconvenient hand-holding, so as to ensure accuracy and reduce hand-held phenomena. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

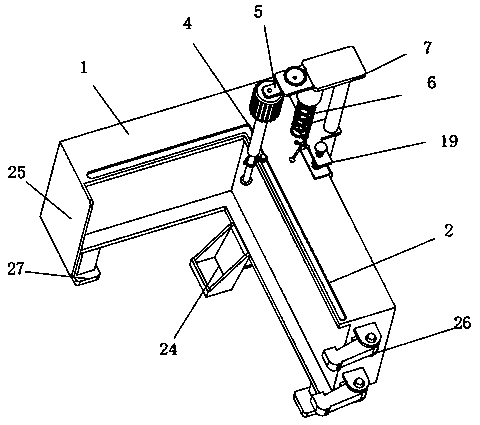

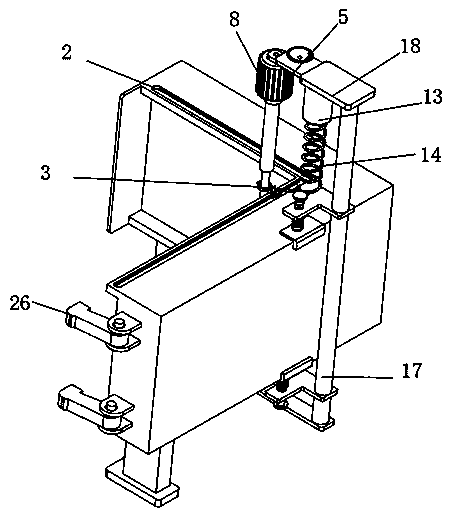

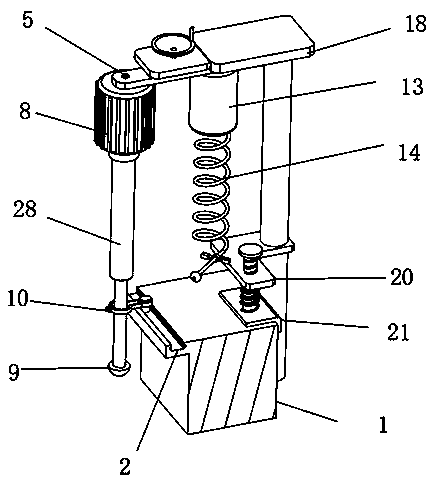

[0028]Specific implementation method: when performing surface treatment on the gap at the inner wall of the small turning wall, push the small turning wall into the inside of the turning wall placement frame 1 until one end of the turning wall is in contact with the limit baffle 25 and then stop pushing the turning wall workpiece , turn the two dampers 26 at the other end of the turning wall placement frame 1 to the side wall of the small turning wall part, and through the common limiting effect of the damper 26 and the limit baffle 25, it is convenient to limit the small turning wall part at Turn the wall to place the inside of the frame 1, open the fastening bolt 12 on the outside of the metal ring sleeve 10, pass the telescopic rod 28 between the metal ring sleeves 10, tighten the metal ring sleeve 10, and put the grinding head on the bottom of the telescopic rod 28 9 close to the gap, the metal ring 10 will limit the telescopic rod 28 at the gap, start the motor 8, because ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com