Inverted blue light quantum-dot thin film electroluminescence device

An electroluminescent device, quantum dot light emitting technology, applied in the direction of electric solid state devices, electrical components, semiconductor devices, etc., can solve the problems of large HOMO energy level, high hole injection barrier, and difficult hole injection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0051] In addition, the present invention also provides a method for preparing the above-mentioned inverted blue light quantum dot thin film electroluminescent device 10, such as image 3 As shown, the method includes the following steps S110-S140.

[0052] S110, providing a substrate, and forming a cathode on the substrate.

[0053]The material of the substrate can be glass, and the substrate can be ultrasonically treated with detergent, acetone, ethanol and isopropanol for 15 minutes each. Then vapor deposition, sputtering, sputtering or electrochemical vapor deposition on the substrate to form the cathode. The material of the cathode can be indium tin oxide (ITO), fluorine-doped tin oxide (FTO), aluminum-doped zinc oxide (AZO), indium-doped zinc oxide (IZO), etc., and the thickness of the cathode is 80nm-200nm.

[0054] Preferably, indium tin oxide (ITO) is sputtered onto the glass substrate by sputtering.

[0055] In this embodiment, after the cathode is formed on the s...

Embodiment 1

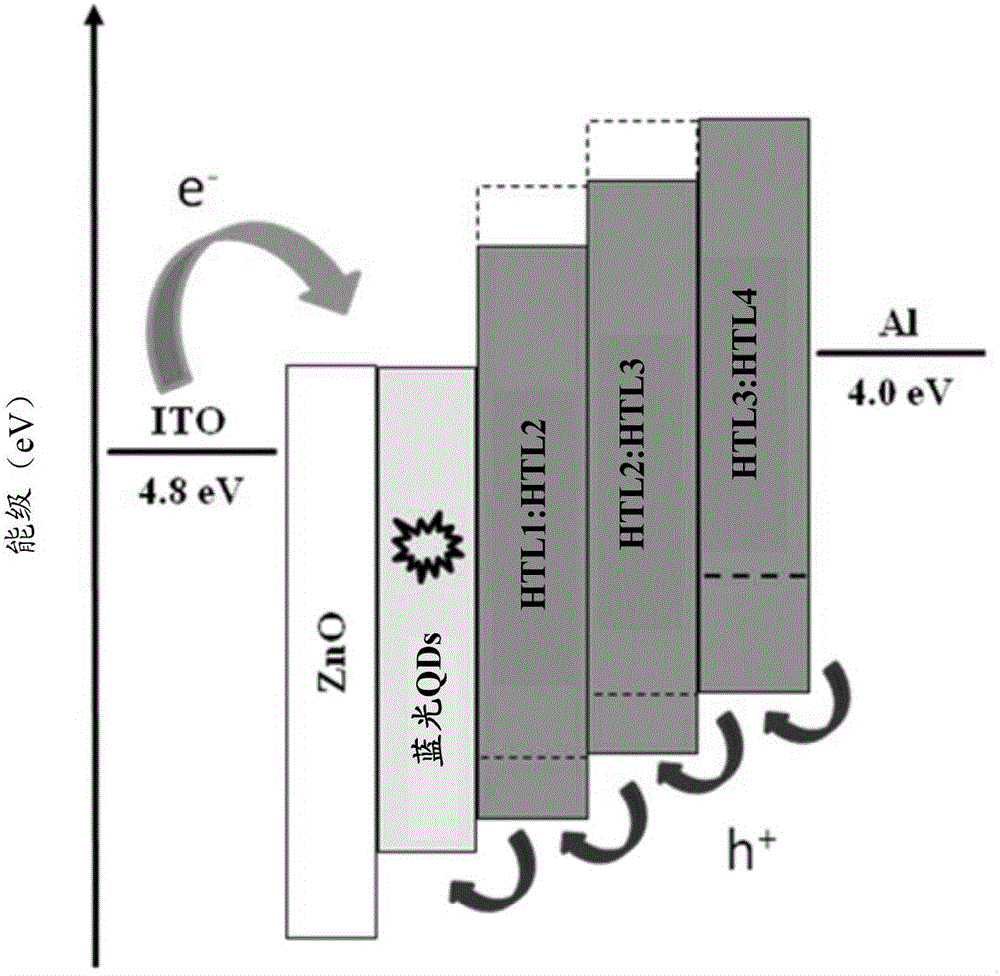

[0067] The structure of the inverted blue quantum dot thin film electroluminescent device is a substrate, a cathode, an electron transport layer, a blue quantum dot light-emitting layer, a hole transport layer and an anode, wherein the hole transport layer includes a first hole transport layer, a second hole transport layer stacked in sequence. Two hole transport layers and a third hole transport layer. The side of the first hole transport layer away from the second hole transport layer is in close contact with the blue light quantum dot light-emitting layer. Wherein, the thickness of the first hole transport layer is 8 nm, and the material of the first hole transport layer is a mixture of the first hole transport material (HTL1) and the second hole transport material (HTL2), wherein HTL1 is 2- Hydroxy-3-methyl-2-cyclopenten-1-one (mCP), HTL2 is 3,5-di(9hydro-carbazol-9-yl)-nitrogen, nitrogen-biphenylamine (DCDPA), The mass ratio of mCP to DCDPA is 3:2. The thickness of the ...

Embodiment 2

[0073] The thickness of the first hole transport layer in the inverted blue light quantum dot thin film electroluminescence device of the present embodiment is 10nm, and the material of the first hole transport layer is the mixture that HTL1 and HTL2 form, and wherein HTL1 is mCP, and HTL2 is DCDPA, The mass ratio of mCP to DCDPA is 3:2. The thickness of the second hole transport layer is 20nm, and the material of the second hole transport layer is a mixture of HTL2 and HTL3, wherein HTL2 is DCDPA, HTL3 is BTPD, and the mass ratio of DCDPA to BTPD is 3:4. The thickness of the third hole transport layer is 30nm, and the material of the third hole transport layer is a mixture of HTL3 and HTL4, wherein HTL3 is BTPD, and HTL4 is WO 3 , BTPD and WO 3 The mass ratio is 2:3. All the other are identical with embodiment 1.

[0074] The specific preparation method of the inverted blue light quantum dot thin film electroluminescent device is the same as that of Example 1.

[0075] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com