Automatic device capable of realizing wall thickness deviation measurement of steel tube

An automatic device and deviation measurement technology, applied in the direction of measurement device, optical device, instrument, etc., can solve the problems of complicated wall thickness measurement operation, and achieve the effect of improving production automation rate, high efficiency and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

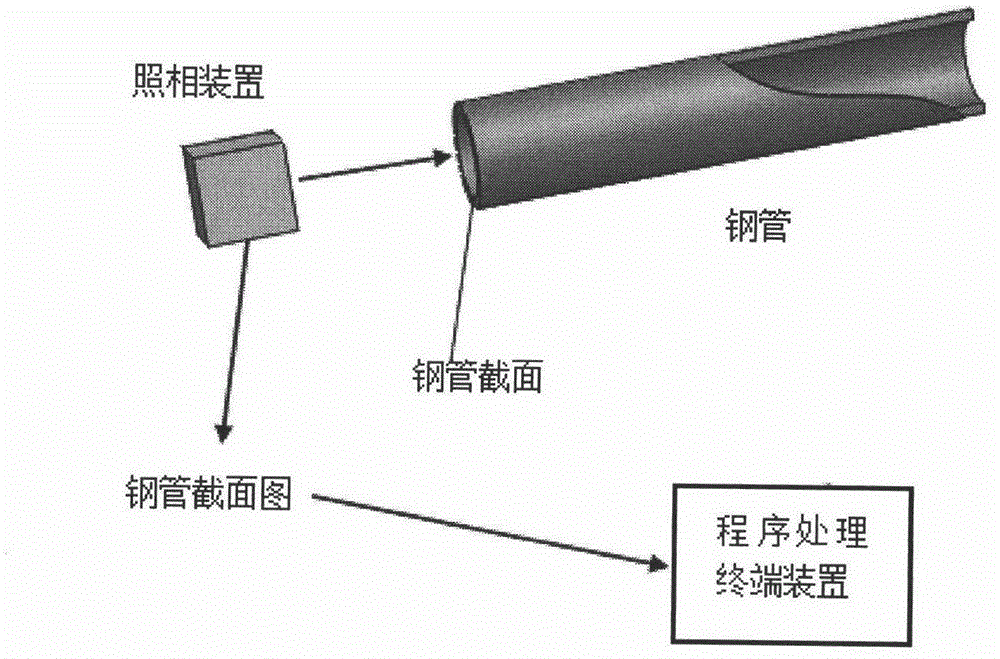

[0026] figure 1 The schematic diagram of the device designed by the present invention is shown, which includes three parts: a steel pipe, a photographing device and a program processing device.

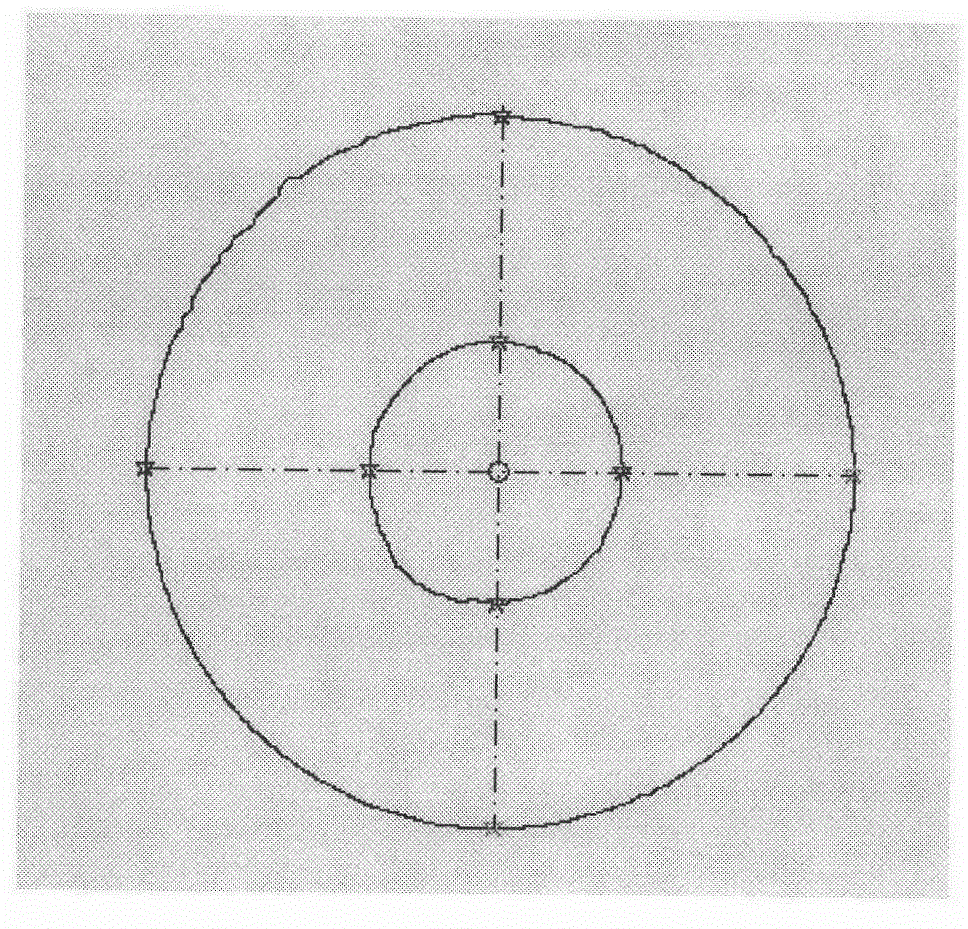

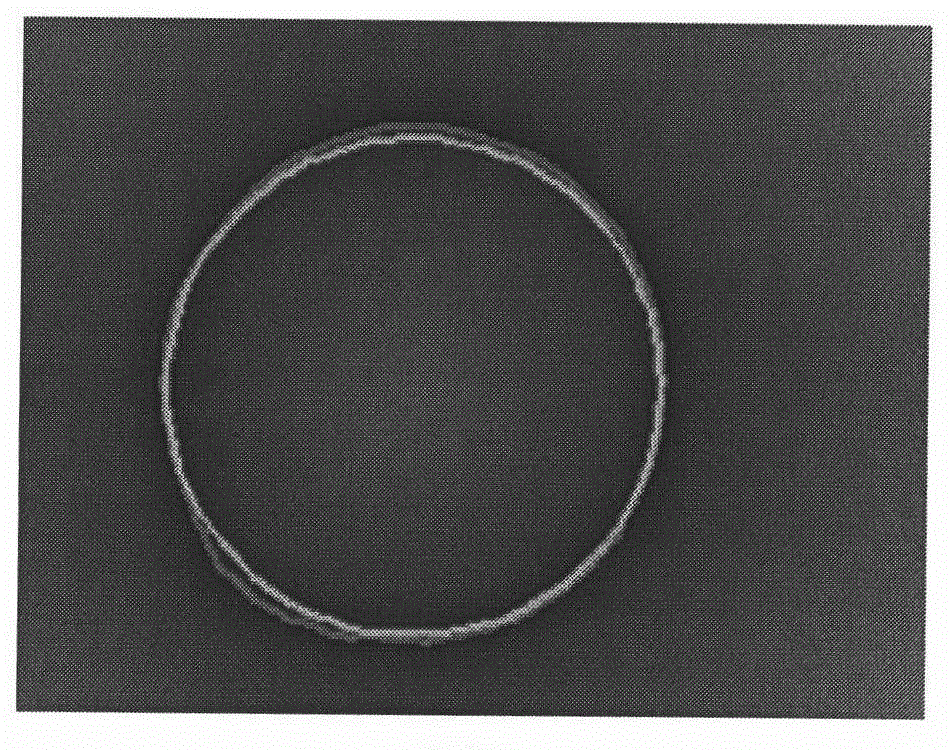

[0027] Illustrate with a steel pipe cross-section obtained after scanning, figure 2 Shown is the profile of the steel pipe after the treatment of the present invention. The useful information area of the original image is intercepted, the image is binarized, sharpened, and the image noise is removed, and then the "canny" operator of the edge function is used to obtain the image contour map, and its pixel data is stored as a large sparse matrix, and the pixel coordinates of the large circle are taken out Make its least squares circle to get its center coordinates. With the center of the big circle as the center, a set of wall thickness value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com