Nailing control method and system based on visual positioning of seat cushion

A technology of visual positioning and control system, applied in image analysis, instrument, calculation, etc., can solve the problems of low level, inability to produce automation, and insufficient nailing position accuracy, and achieve the effect of improving production automation and improving nailing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

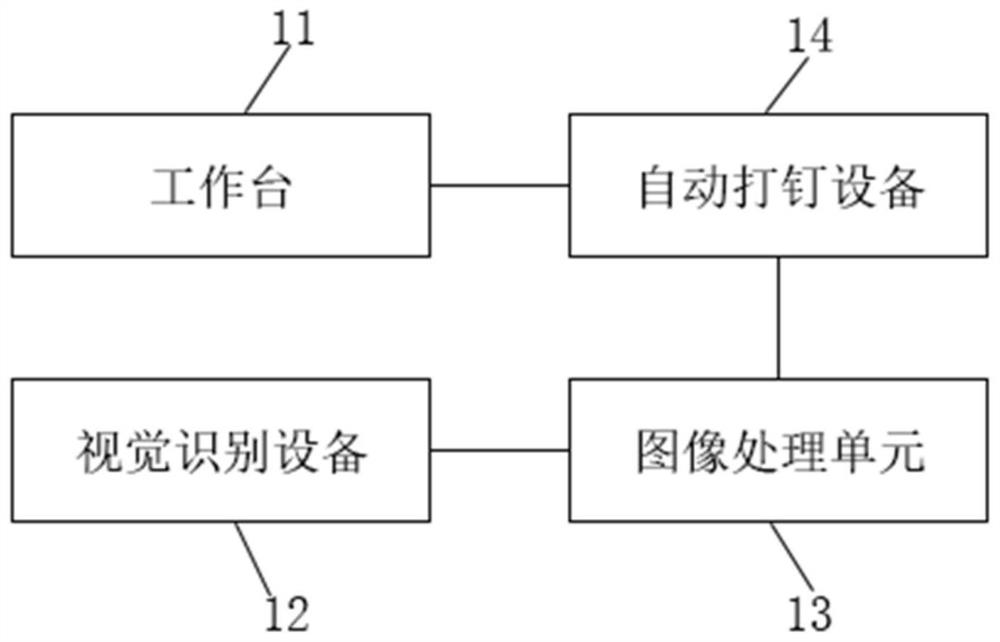

[0030] This embodiment provides a nailing control system based on visual positioning of seat cushion, such as figure 1 As shown, it includes a workbench 11, a visual recognition device 12, an image processing unit 13, and an automatic nailing device 14;

[0031] Workbench 11, used to place and fix the seat cushion;

[0032] The visual recognition device 12 is used to collect image information on the side of the seat cushion to be nailed, and send the collected image information to the image processing unit 13;

[0033] The image processing unit 13, connected with the visual recognition device 12, is used for receiving image information, and processing the received image information to obtain the center position information of the area to be nailed;

[0034] The automatic nailing device 14 is connected to the workbench 11 and the image processing unit 13 respectively, and is used to adjust the nail gun head of the nailing machine to the center of the area to be nailed accordin...

Embodiment 2

[0039] This embodiment provides a nailing control method based on visual positioning of a seat cushion, including the control system in the first embodiment;

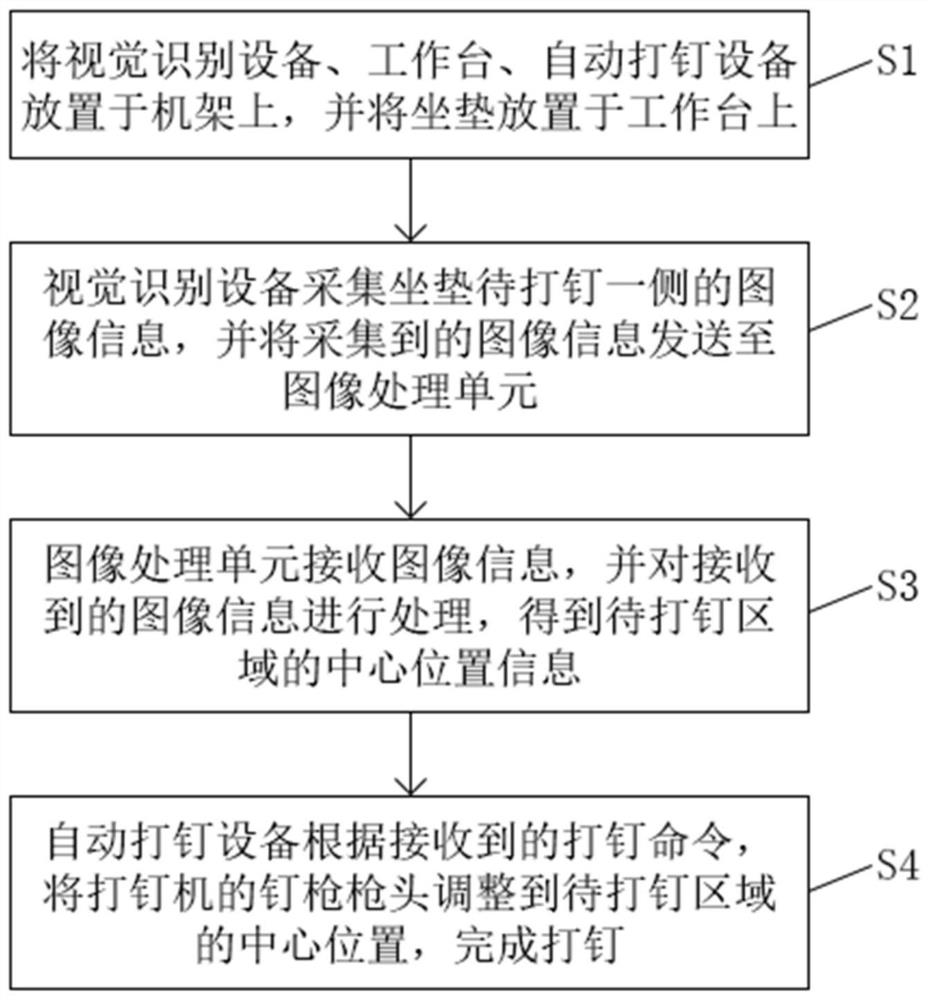

[0040] like figure 2 As shown, the control method includes:

[0041] S1. Place the visual recognition equipment, workbench, and automatic nailing equipment on the rack, and place the seat cushion on the workbench;

[0042] S2. The visual recognition device collects image information on the side of the cushion to be nailed, and sends the collected image information to the image processing unit;

[0043] S3. The image processing unit receives the image information, and processes the received image information to obtain the center position information of the area to be nailed;

[0044] S4. The automatic nailing device adjusts the nail gun head of the nailing machine to the center of the area to be nailed according to the received nailing command to complete the nailing.

[0045] In step S2, the visual recognition devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com