Mining online pressure-measuring device based on optical fiber

A pressure measuring device and mine-used technology, which is applied in measurement, wellbore/well components, earthwork drilling and mining, etc. It can solve the problems of lack of long-distance monitoring technology, long data reading and updating cycle, and unsatisfactory gas control effect. , to achieve fast and effective real-time online monitoring and monitoring, long-term stable and reliable sensitivity, and the effect of eliminating potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

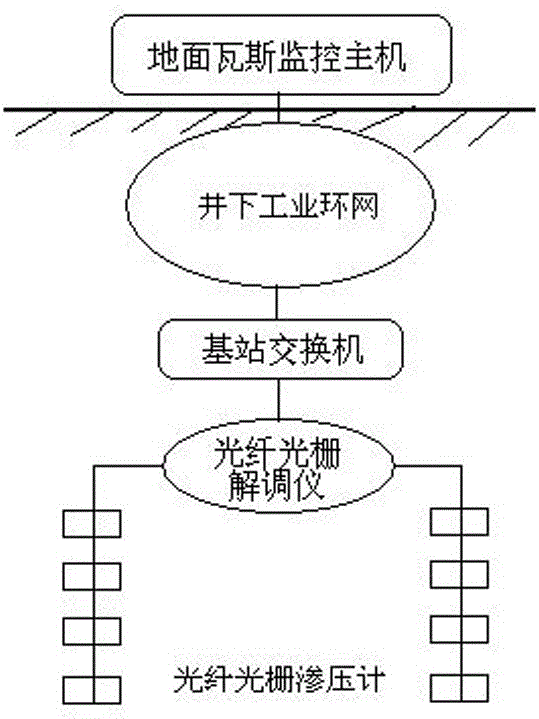

[0016] Such as figure 1 As shown, an online mine pressure measurement device based on optical fiber includes a ground gas monitoring host, an underground industrial ring network connected in sequence, a number of base station switches connected to the underground industrial ring network, and a fiber grating demodulator connected to the base station switch. Fiber Bragg grating osmometers connected to the fiber Bragg grating demodulator through transmission cables. The ring network is transmitted to the ground gas monitoring host for real-time online monitoring and monitoring of coal seam gas pressure.

[0017] The surface gas monitoring host analyzes, stores, and displays the collected data reported on the underground industrial ring network, and provides data export, thereby realizing real-time online monitoring of the system, and simultaneously displaying multiple real-time data and relevant location parameters.

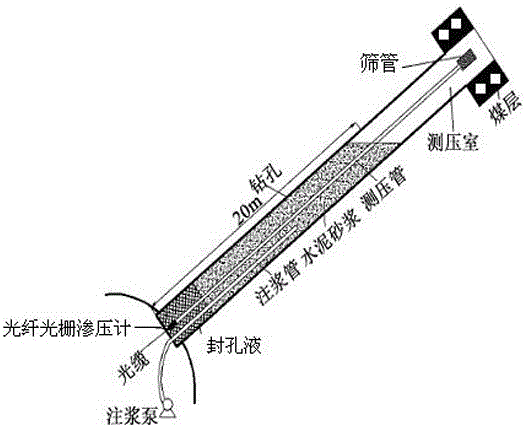

[0018] Such as figure 2 As shown, the installation method o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com