Hydrochloric acid waste liquid regeneration method and system

A technology of hydrochloric acid waste liquid and regeneration system, which is applied in separation methods, chemical instruments and methods, and the use of liquid separation agents, etc., can solve the problems of energy saving and consumption reduction, high fuel consumption, and severe autumn and winter seasons, so as to save construction costs and transformation cost, reduction of flue gas volume, and the effect of moisture reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

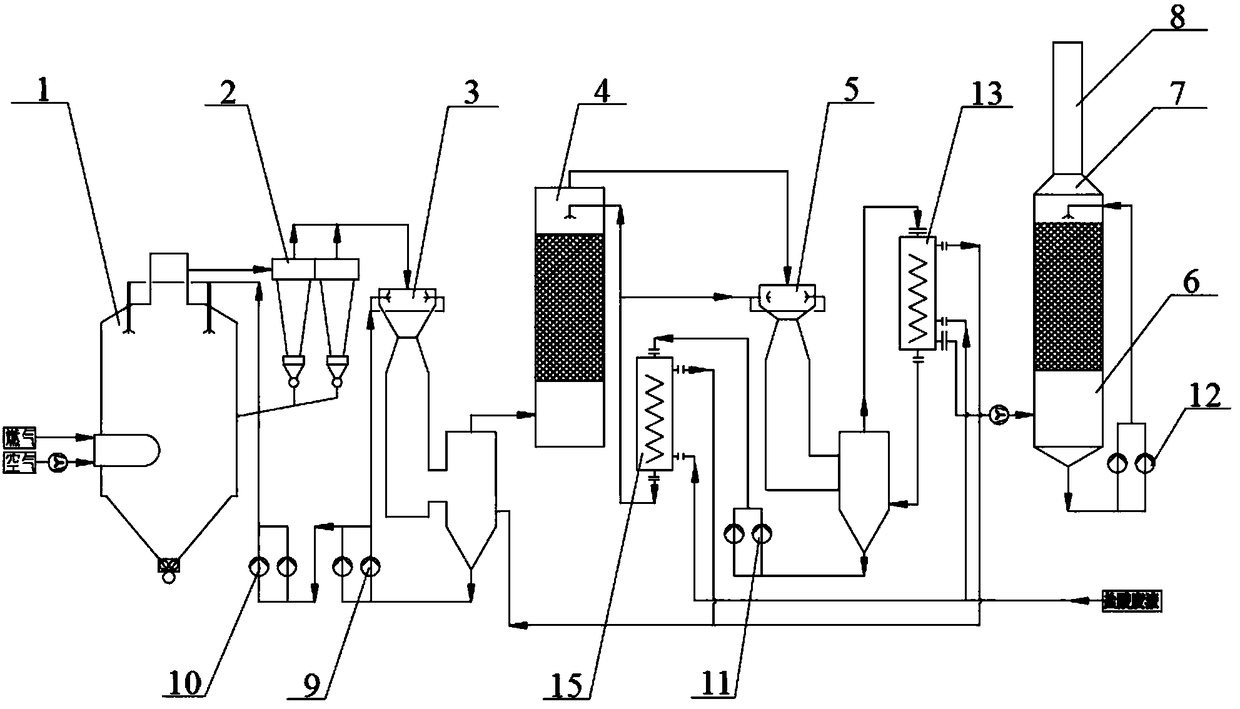

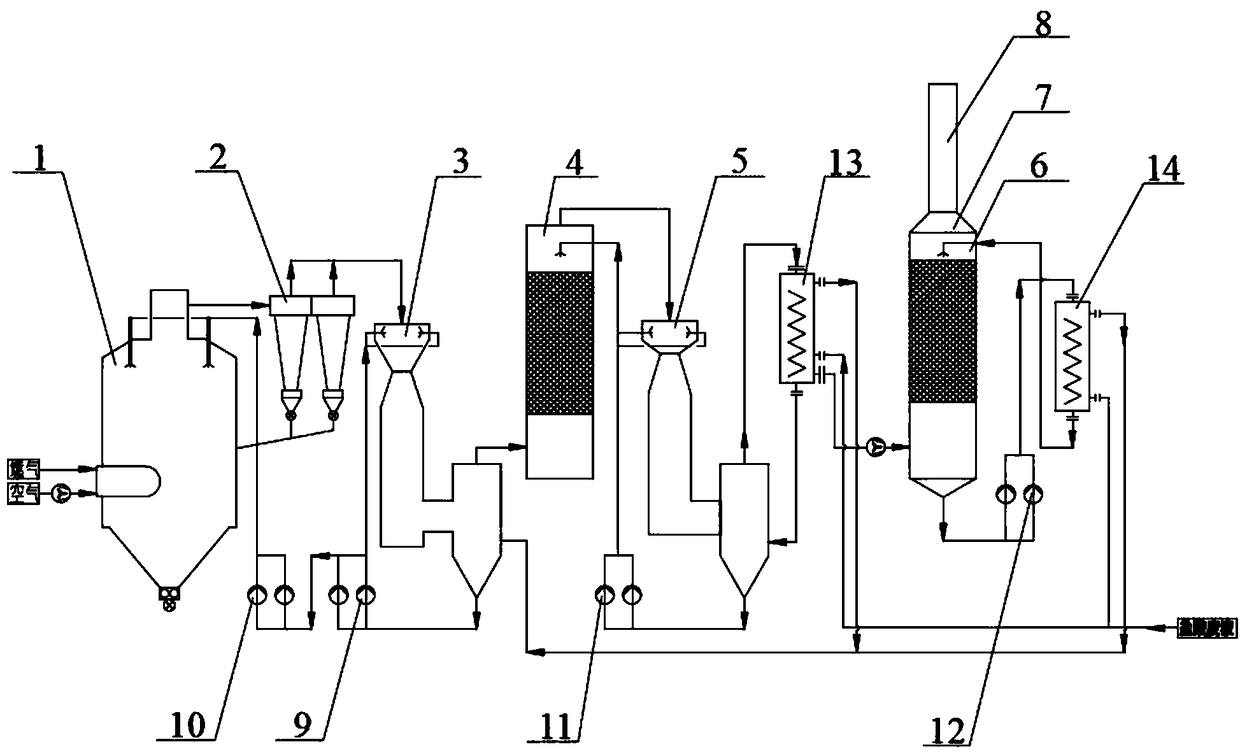

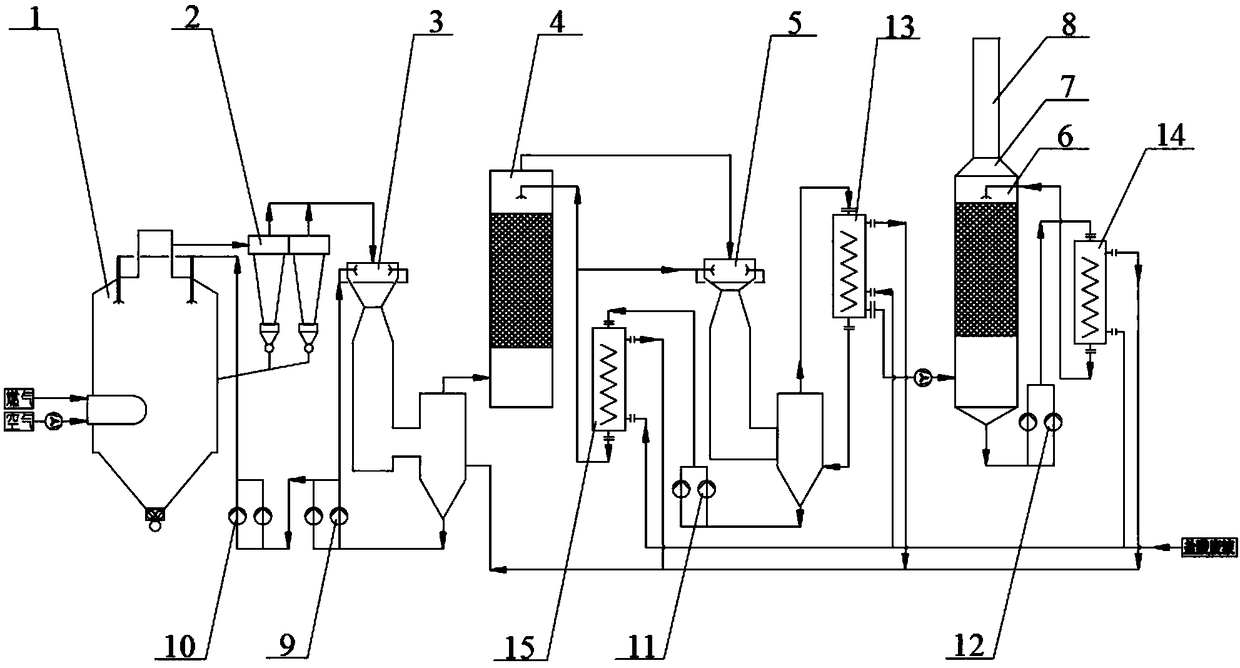

[0021] This embodiment relates to a regeneration treatment method for hydrochloric acid waste liquid, comprising the following steps:

[0022] (1) After the hydrochloric acid waste liquid directly enters the Venturi pre-concentrator 3 for heating and concentrating, it is sprayed into the roasting furnace 1 with atomized droplets after being pressurized by the Venturi pre-concentrator circulating liquid pump 9 and the roasting furnace feed pump 10, After the droplet undergoes a chemical reaction in the roaster 1, it generates 2 O, O 2 , CO 2 , N 2 and a small amount of Fe 2 o 3 High temperature flue gas of powder (390~410℃).

[0023] (2) The above-mentioned high-temperature flue gas enters the Venturi pre-concentrator 3 to exchange heat with the hydrochloric acid waste liquid, the flue gas is cooled and dedusted, and the hydrochloric acid waste liquid is heated, and the temperature of the flue gas is reduced to 95-100°C.

[0024] (3) The flue gas from the Venturi pre-conc...

Embodiment 2

[0031] The embodiment of the present invention relates to a hydrochloric acid waste liquid regeneration method, which can solve at least part of the problems of the prior art. This method is basically the same as the steps of the regeneration treatment method of hydrochloric acid waste liquid in the above-mentioned embodiment one, and the specific steps are not repeated here; this method is improved on the basis of the method in embodiment one, specifically: hydrochloric acid waste liquid After being heated and concentrated in the Venturi preconcentrator 3, it is sprayed into the roasting furnace 1, and the roasting flue gas produced is subjected to subsequent hydrochloric acid regeneration treatment and purification treatment; in the hydrochloric acid waste liquid entering the Venturi preconcentrator 3, at least part of it is pre Heated hydrochloric acid waste.

[0032]By preheating the hydrochloric acid waste liquid, the heat required for heating and concentrating the hydroc...

Embodiment 3

[0038] The embodiment of the present invention relates to a hydrochloric acid waste liquid regeneration method, which can solve at least part of the problems of the prior art. This method is basically the same as the steps of the regeneration treatment method of the hydrochloric acid waste liquid in the above-mentioned embodiment one, and the specific steps are not repeated here; this method is improved on the basis of the method in the embodiment one, specifically: recovering the first Part of the waste heat of the circulating liquid of the stage washing mechanism 5 is used to preheat at least a part of the hydrochloric acid waste liquid entering the Venturi preconcentrator 3, and the circulating liquid after heat exchange is sprayed into the first stage washing mechanism 5 and / or In the absorption tower 4. That is, a second heat exchange mechanism 15 is set on the circulating liquid pipeline of the first-stage washing mechanism 5, and the hydrochloric acid waste liquid is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com