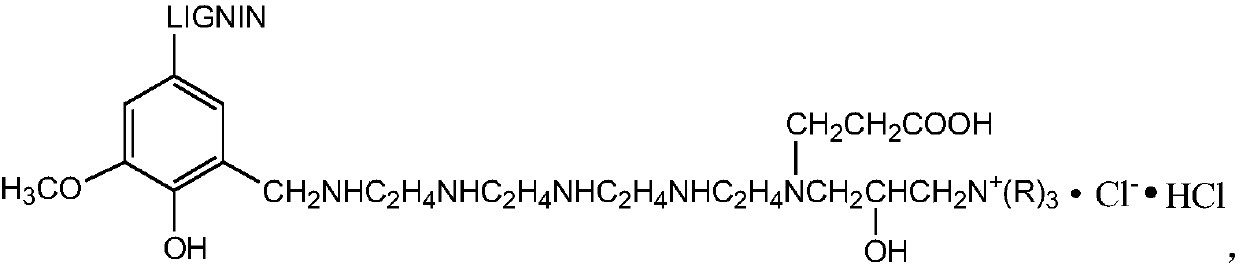

A kind of lignin polyamine quaternary ammonium salt cationic asphalt emulsifier and its preparation method

A quaternary ammonium salt cation, asphalt emulsifier technology, applied in building components, building insulation materials, construction and other directions, can solve the problems of requiring high temperature reaction, high temperature reaction, complicated preparation steps, etc., achieve good storage stability, improve emulsification performance , the effect of increasing hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] (1) Preparation of lignin polyamine quaternary ammonium salt cationic asphalt emulsifier:

[0049] 1) Add 189.3g of tetraethylenepentamine into the reactor, then dropwise add 72.1g of acrylic acid, stir and react at 45°C for 1h, and obtain reaction intermediate I.

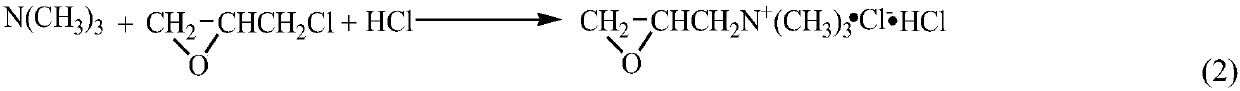

[0050] 2) In another reactor, add 193.1g of 33% (mass fraction) trimethylamine aqueous solution, gradually add 131.2g of 30% (mass fraction) industrial hydrochloric acid, then gradually add 97.1g of epichlorohydrin, and stir and react at 45°C for 2h to obtain Reaction Intermediate II.

[0051] 3) In another reactor, 283.0 g of lignin was dissolved in 649.6 g of 10.7% (mass fraction) sodium hydroxide aqueous solution, mixed and stirred for reaction to obtain reaction intermediate III.

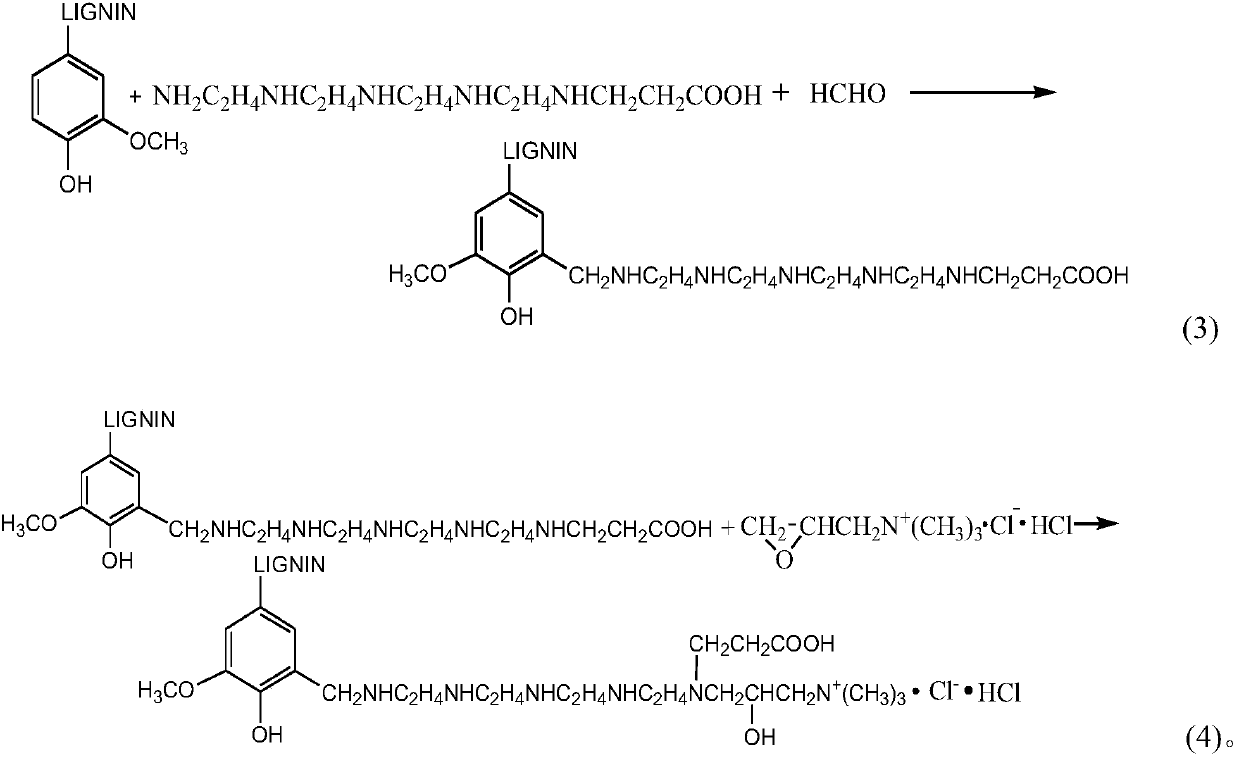

[0052] 4) Add reaction intermediate I to reaction intermediate III, then gradually add 92.5 g of 37% (mass fraction) formaldehyde, and react at 70°C for 3 hours to obtain reaction intermediate IV;

[0053] 5) Gradually add t...

Embodiment 2

[0065] (1) Preparation of lignin polyamine quaternary ammonium salt cationic asphalt emulsifier:

[0066] 1) Add 189.3g of tetraethylenepentamine into the reactor, then dropwise add 72.1g of acrylic acid, stir and react at 45°C for 1h, and obtain reaction intermediate I.

[0067] 2) Add 109.1g triethylamine to another reactor, gradually add 131.2g 30% (mass fraction) industrial hydrochloric acid, then gradually add 97.1g epichlorohydrin, stir and react at 45°C for 2h to obtain reaction intermediate II.

[0068] 3) In another reactor, 283.0 g of lignin was dissolved in 649.6 g of 10.7% (mass fraction) sodium hydroxide aqueous solution, mixed and stirred for reaction to obtain reaction intermediate III.

[0069] 4) Add reaction intermediate I to reaction intermediate III, then gradually add 92.5 g of 37% (mass fraction) formaldehyde, and react at 60°C for 4 hours to obtain reaction intermediate IV;

[0070] 5) Gradually add the reaction intermediate II to the reaction intermedi...

Embodiment 3

[0081] (1) Preparation of lignin polyamine quaternary ammonium salt cationic asphalt emulsifier:

[0082] 1) Add 189.3g of tetraethylenepentamine into the reactor, then dropwise add 72.1g of acrylic acid, stir and react at 45°C for 1h, and obtain reaction intermediate I.

[0083] 2) In another reactor, add 189.6g 85% (mass fraction) triethanolamine aqueous solution, gradually add 131.2g 30% industrial hydrochloric acid, then gradually add 97.1g epichlorohydrin, stir and react at 45°C for 2h, and obtain the reaction medium Body II.

[0084] 3) In another reactor, 283.0 g of lignin was dissolved in 649.6 g of 10.7% (mass fraction) sodium hydroxide aqueous solution, mixed and stirred for reaction to obtain reaction intermediate III.

[0085] 4) Add the reaction intermediate I to the reaction intermediate III, then gradually add 92.5g of 37% (mass fraction) formaldehyde, react at 80°C for 2 hours, and obtain the reaction intermediate IV;

[0086] 5) Gradually add the reaction in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com