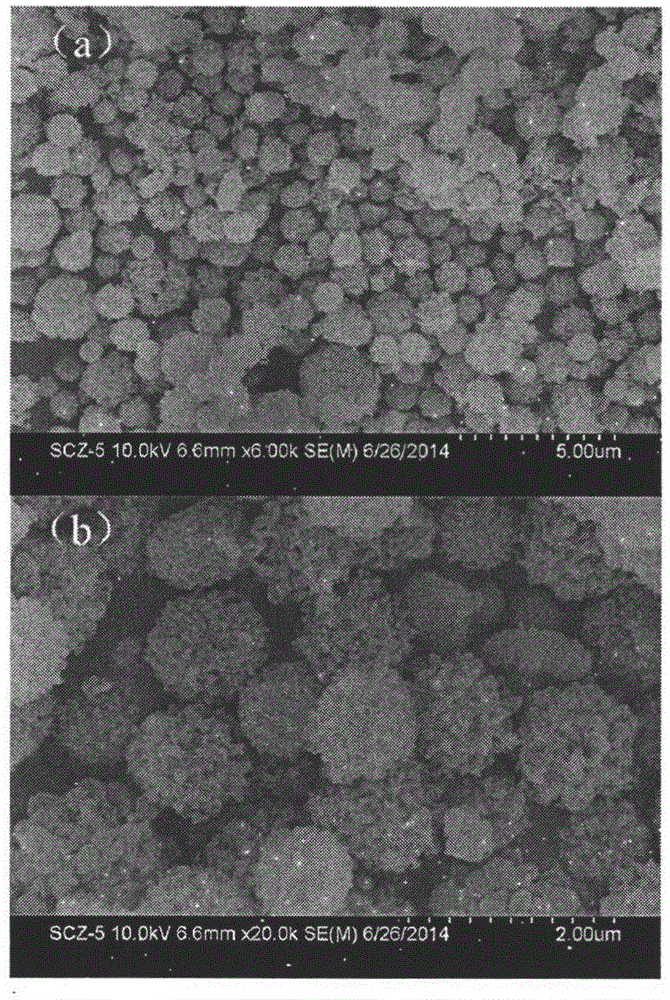

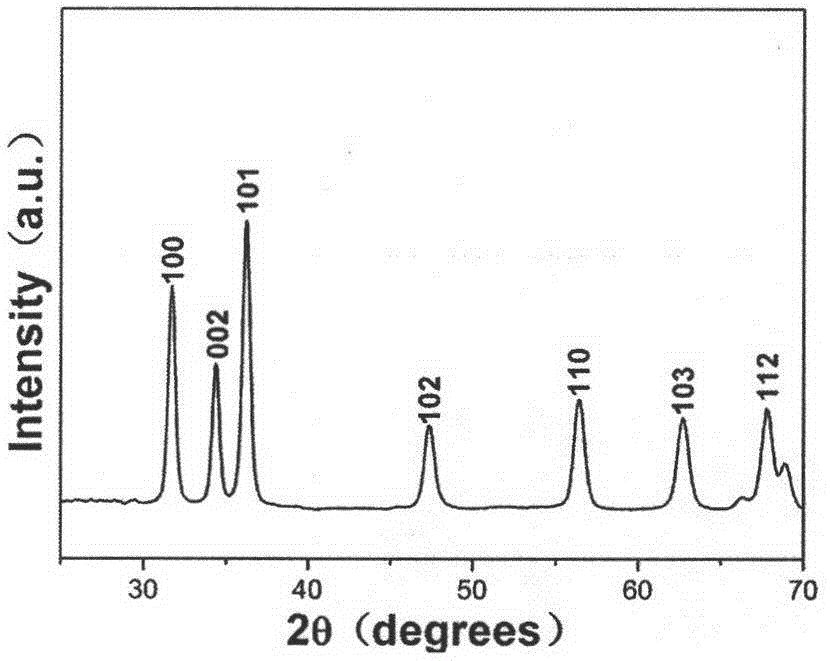

Preparation method of porous pompon-like zinc oxide material

A technology of porous zinc oxide and zinc oxide, applied in the direction of zinc oxide/zinc hydroxide, nanotechnology for materials and surface science, nanotechnology, etc., can solve the problems such as porous pompom-shaped zinc oxide materials that are rarely reported, and achieve Large application value, large-scale industrial production, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A preparation method of porous pompomed zinc oxide, comprising the following steps:

[0018] (1) taking distilled water as solvent preparation concentration is the zinc nitrate solution A of 0.1mol / L, preparation concentration is the glucose solution B of 2mol / L, preparation concentration is the acrylic acid solution C of 0.6mol / L;

[0019] (2) Mix solution A, solution B and solution C in a volume ratio of 1:1:1, and the obtained mixed solution D is stirred at room temperature for a certain period of time;

[0020] (3) Pour the clear mixed solution D obtained above into a 50mL polytetrafluoroethylene autoclave for hydrothermal reaction at 180°C for 6 to 12 hours;

[0021] (4) when the autoclave is naturally cooled to room temperature, the obtained precipitate is taken out, then alternately centrifugally washed with distilled water and absolute ethanol, and then dried in an oven at 60°C;

[0022] (5) Finally, heat treatment of the dried zinc oxide precursor at 500° C. f...

Embodiment 2

[0025] A preparation method of porous pompomed zinc oxide, comprising the following steps:

[0026] (1) taking distilled water as solvent preparation concentration is the zinc acetate solution A of 0.1mol / L, preparation concentration is the glucose solution B of 2mol / L, preparation concentration is the acrylic acid solution C of 0.6mol / L;

[0027] (2) Mix solution A, solution B and solution C in a volume ratio of 1:1:1, and the obtained mixed solution D is stirred at room temperature for a certain period of time;

[0028] (3) Pour the clear mixed solution D obtained above into a 50mL polytetrafluoroethylene autoclave for hydrothermal reaction at 180°C for 6 to 12 hours;

[0029] (4) when the autoclave is naturally cooled to room temperature, the obtained precipitate is taken out, then alternately centrifugally washed with distilled water and absolute ethanol, and then dried in an oven at 60°C;

[0030] (5) Finally, heat treatment of the dried zinc oxide precursor at 500° C. f...

Embodiment 3

[0032] A preparation method of porous pompomed zinc oxide, comprising the following steps:

[0033] (1) taking distilled water as solvent preparation concentration is the zinc sulfate solution A of 0.1mol / L, preparation concentration is the glucose solution B of 2mol / L, preparation concentration is the acrylic acid solution C of 0.6mol / L;

[0034] (2) Mix solution A, solution B and solution C in a volume ratio of 1:1:1, and the obtained mixed solution D is stirred at room temperature for a certain period of time;

[0035] (3) Pour the clear mixed solution D obtained above into a 50mL polytetrafluoroethylene autoclave for hydrothermal reaction at 180°C for 6 to 12 hours;

[0036] (4) when the autoclave is naturally cooled to room temperature, the obtained precipitate is taken out, then alternately centrifugally washed with distilled water and absolute ethanol, and then dried in an oven at 60°C;

[0037] (5) Finally, heat treatment of the dried zinc oxide precursor at 500° C. f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com