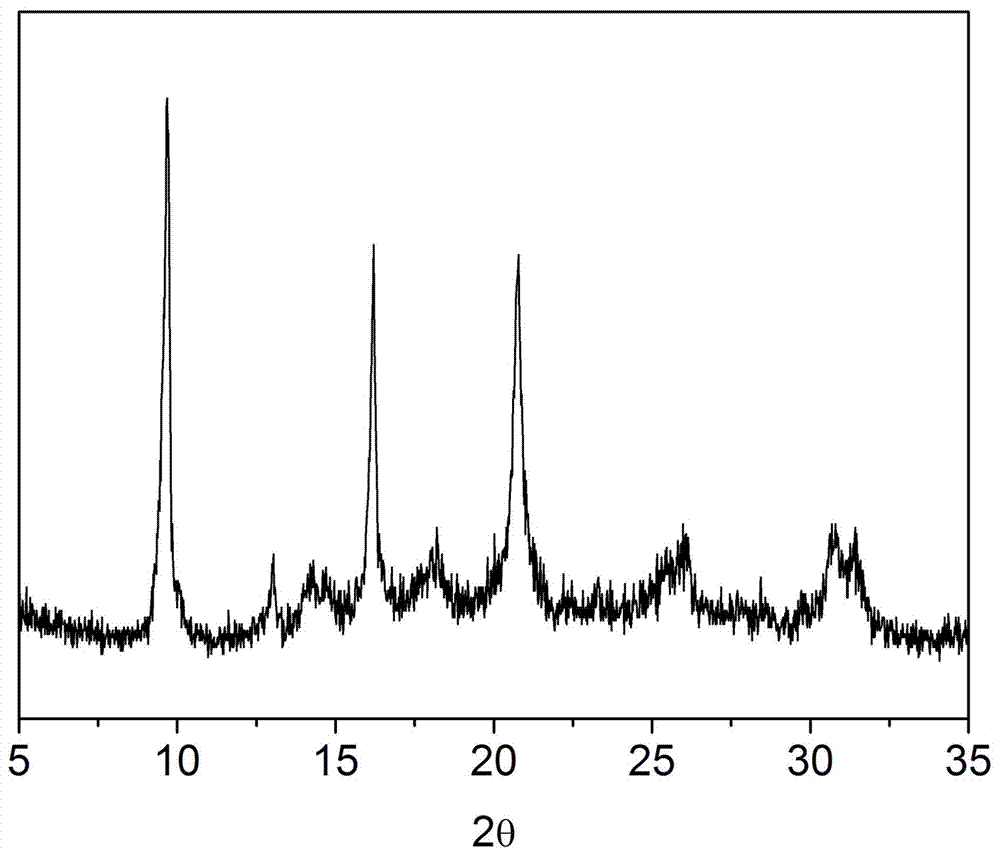

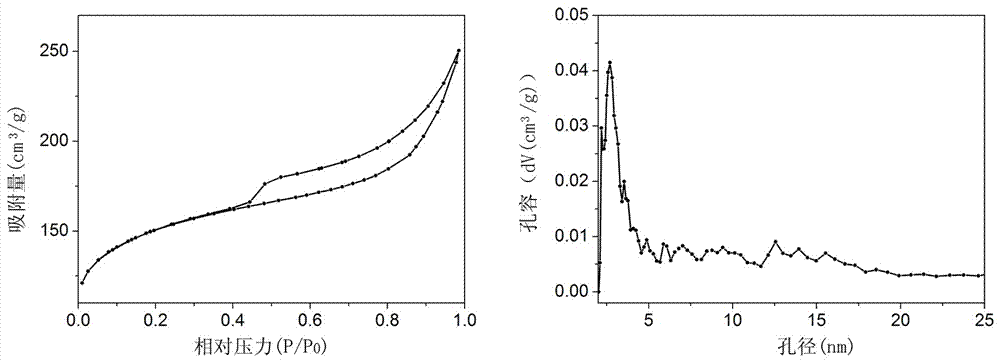

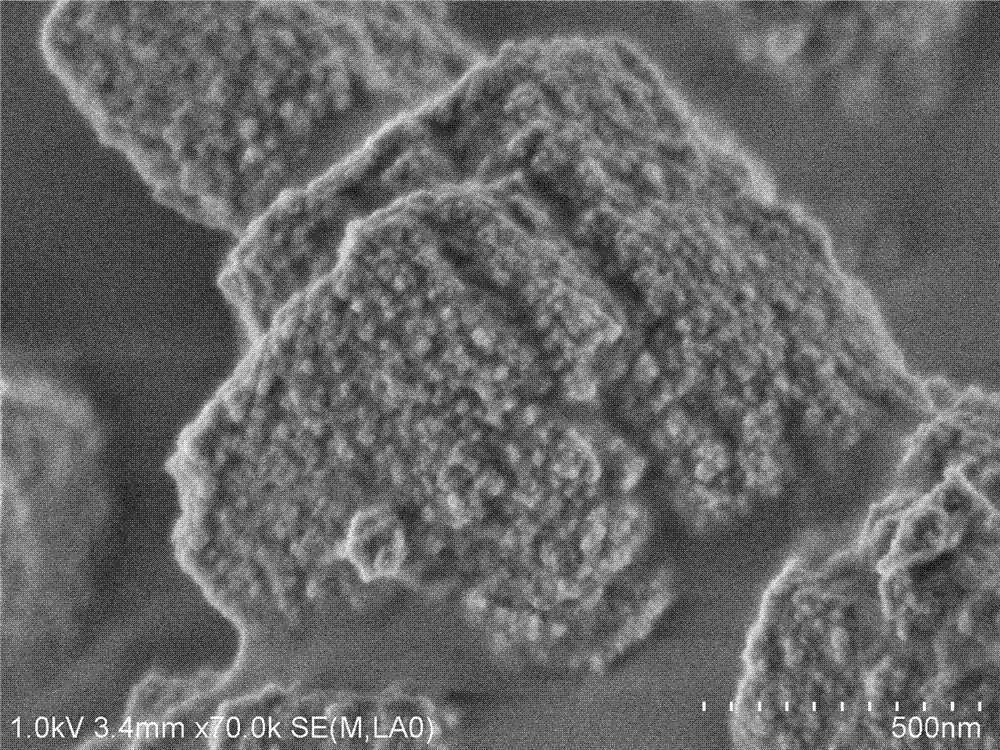

A kind of preparation method of mesoporous sapo-34 molecular sieve

A molecular sieve and solution technology, applied in the direction of molecular sieve and alkali-exchanged phosphate, molecular sieve characteristic silicoaluminophosphate, etc., can solve the problems of large pore diameter, difficult adjustment of silicon-aluminum ratio, and wide distribution in multi-level porous molecular sieves, to overcome Diffusion bottleneck, low cost of preparation, effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 0.7g of PHAPTMS (density 1.07g / ml), mix it with 3ml of methanol and stir for 5min, slowly add 1ml of deionized water to make a solution; 2 / g gas phase SiO 2 After mixing with 10ml of deionized water and stirring for 5 minutes, it was added to the above solution, heated to 60° C. and stirred for 5 hours at a constant temperature to obtain a silicon source solution.

[0029] Add 20g of TEAOH aqueous solution with a mass concentration of 20% into a beaker, place it in a water bath at 60°C and stir it. After 5ml of water is evaporated, take it out at room temperature, add 2.44g of pseudo-boehmite, stir for 3 hours, and slowly add a mass concentration of 85 %H 3 PO 4 The solution was 2.38ml, stirred for 30 minutes, then added to the silicon source solution and stirred for 2-3 hours to obtain a gel.

[0030] Put the obtained gel into a reaction kettle lined with polytetrafluoroethylene, and conduct a hydrothermal crystallization reaction at 160°C for 10 days. ℃ cal...

Embodiment 2

[0037] Weigh 0.9g of PHAPTMS (density 1.07g / ml), mix it with 3ml of methanol and stir for 5min, slowly add 1ml of deionized water to make a solution; 2 / g gas phase SiO 2 After mixing with 10ml of deionized water and stirring for 5 minutes, it was added to the above solution, heated to 60° C. and stirred for 5 hours at a constant temperature to obtain a silicon source solution.

[0038] Add 23g of TEAOH aqueous solution with a mass concentration of 20% into a beaker, place it in a water bath at 60°C and stir it. After 8ml of water is evaporated, take it out at room temperature, add 2.44g of pseudo-boehmite, stir for 3 hours, and slowly add a mass concentration of 85 %H 3 PO 4 The solution was 2.38ml, stirred for 30 minutes, then added to the silicon source solution and stirred for 2-3 hours to obtain a gel.

[0039] Put the obtained gel into a reaction kettle lined with polytetrafluoroethylene, and conduct a hydrothermal crystallization reaction at 160°C for 10 days. ℃ cal...

Embodiment 3

[0042] Weigh 0.9g of PHAPTMS (density 1.07g / ml), mix it with 3ml of methanol and stir for 5min, slowly add 1ml of deionized water to make a solution; 2 / g gas phase SiO 2 After mixing with 10ml of deionized water and stirring for 5 minutes, it was added to the above solution, heated to 60° C. and stirred for 5 hours at a constant temperature to obtain a silicon source solution.

[0043] Add 20g of TEAOH aqueous solution with a mass concentration of 20% into a beaker, place it in a water bath at 60°C and stir, after evaporating 7ml of water, take it out at room temperature, add 2.44g of pseudo-boehmite, stir for 3 hours, and slowly dropwise add a mass concentration of 85 %H 3 PO 4 The solution was 2.38ml, stirred for 30 minutes, then added to the silicon source solution and stirred for 2-3 hours to obtain a gel.

[0044] Put the obtained gel into a reaction kettle with a polytetrafluoroethylene liner, and conduct a hydrothermal crystallization reaction at 180°C for 6 days. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com