Multi-unit cubic star main load-bearing structure based on carbon fiber composite

A composite material and carbon fiber technology, which is used in artificial satellites, space navigation equipment, space navigation aircraft, etc., can solve the problems of increasing the structural mass of the CubeSat, reducing the load-to-structure-to-mass ratio, and complicating the composition and assembly. Difficulty and structural quality, enhanced impact resistance, improved stiffness and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

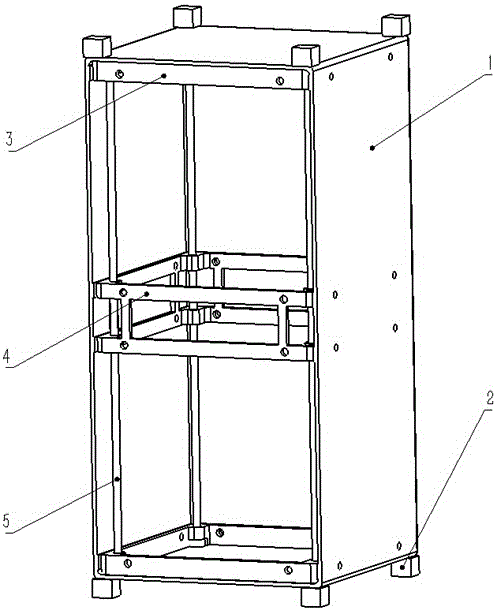

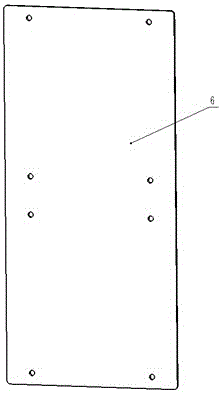

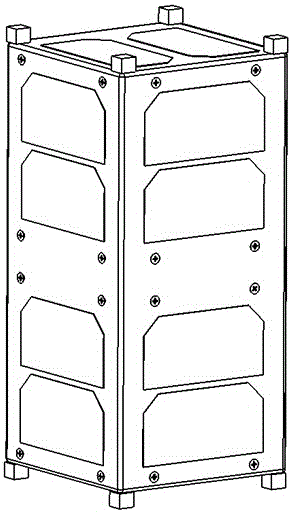

[0036] combine figure 1 , figure 2 and image 3 , a multi-unit cube star main load-bearing structure based on carbon fiber composite materials, including a box body 1, a corner 2, a first fixed frame 3, a second fixed frame 4, studs 5 and a metal cover 6, four screws The columns 5 are distributed in a trapezoidal shape, with a first fixed frame 3 at both ends and a second fixed frame 4 in the middle. The four studs 5, the first fixed frame 3 and the second fixed frame 4 together form a load-bearing frame. The body 1 is a box without a cover on one side. The load-bearing frame is arranged in the box 1 and is fixed by screws. The metal cover plate 6 is fixed on the coverless end of the box 1 by screws. The corners are respectively glued to the corners 2, and the corners 2 support the cube. The solar battery array is directly set on the outer wall of the box, reducing the number of components and reducing the weight of the structure.

[0037] The box body 1 is made of T700 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com