Novel adsorption device tower for coal mine gas concentration

A technology for coal mine gas and adsorption equipment, which is applied in the fields of gas fuel, petroleum industry, and dispersed particle separation, and can solve the problems of exhaust gas emission, large airflow resistance and high cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

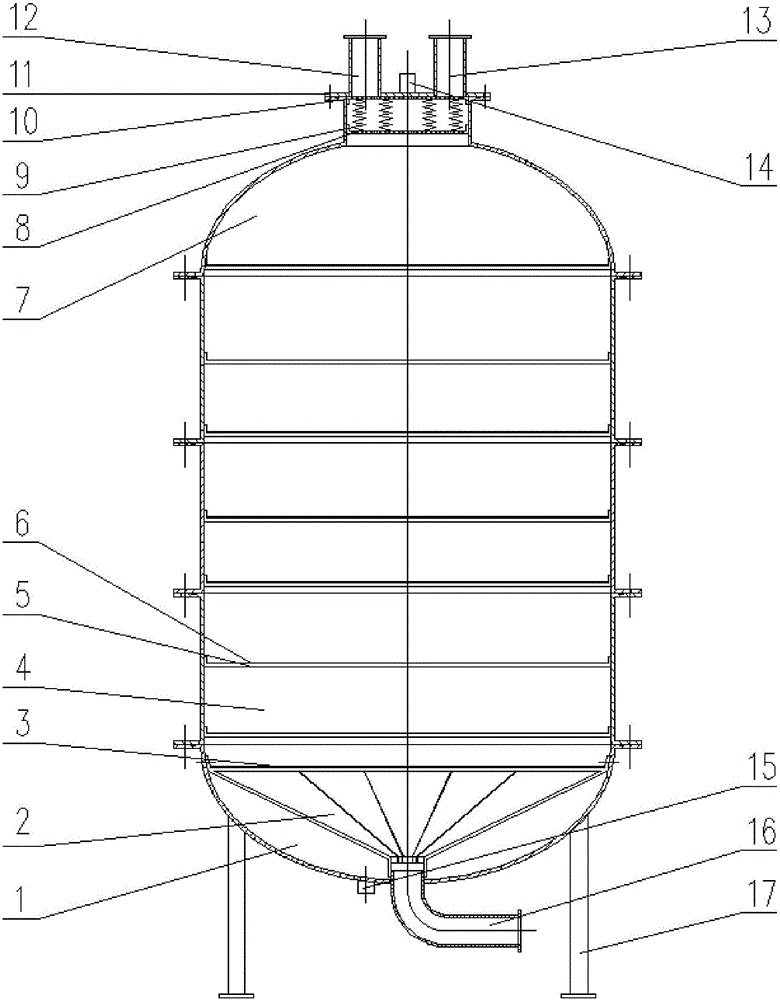

[0013] A new type of adsorption equipment tower for concentration of coal gas, including an adsorption tower body, the lower end of the adsorption tower body is the tower bottom 1, and the upper end is the tower top 7, and there are multiple sections between the tower bottom 1 and the tower top 7 The cylindrical tower body 4 is combined; the cylindrical tower body 4 is provided with a support body 5 and a metal mesh 6, the support body 5 is used to bear the weight of the adsorbent, and the metal mesh 6 ensures that the adsorbent does not fall, and ensures that The gas passes through and has the function of eliminating static electricity; the lower end of the tower bottom 1 is provided with a raw material gas inlet pipe 16, and the gas outlet end of the raw material gas inlet pipe 16 is connected with a splitter 2, and the upper end of the splitter 2 is connected with a diffuser plate 3; The upper end of the tower top 7 is provided with a bottom 8, a spring 9 and a top 10 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com